Operating and Programming — Milling Page 98 808D

ISO

Mode

s

Basic Theory

All the ISO codes described in this unit

can be implemented in the ISO mode of

the 808D system!

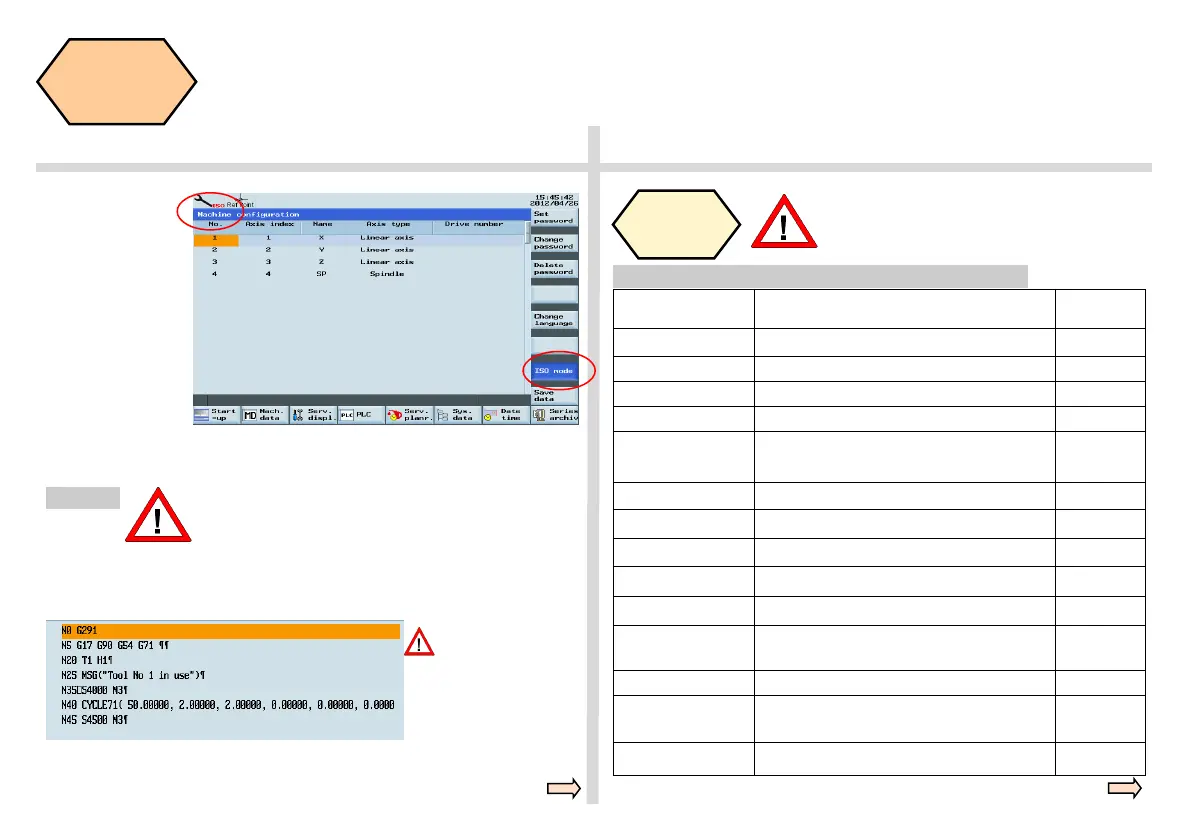

After pressing

“OK”, the sys-

tem restarts auto-

matically.

After restarting,

press “Shift” +

“System - Alarm”

again and if the

symbol in the red

circle appears,

ISO mode is al-

ready activated.

A red ISO appears at the top of the screen and the ISO mode button on

the right is highlighted in blue.

Method 2

When using method 2 to activate the ISO mode,

it will exit ISO mode and return to the default

DIN mode via “Reset” button or after finishing

the machining program.

G291/G290 com-

mands must be set

separately in a line!

Insert G291 in the first line of the ISO part program to be executed and

insert G290 in front of M30.

If ISO is displayed at the top of the screen, it is

activated.

ISO

code

explanation

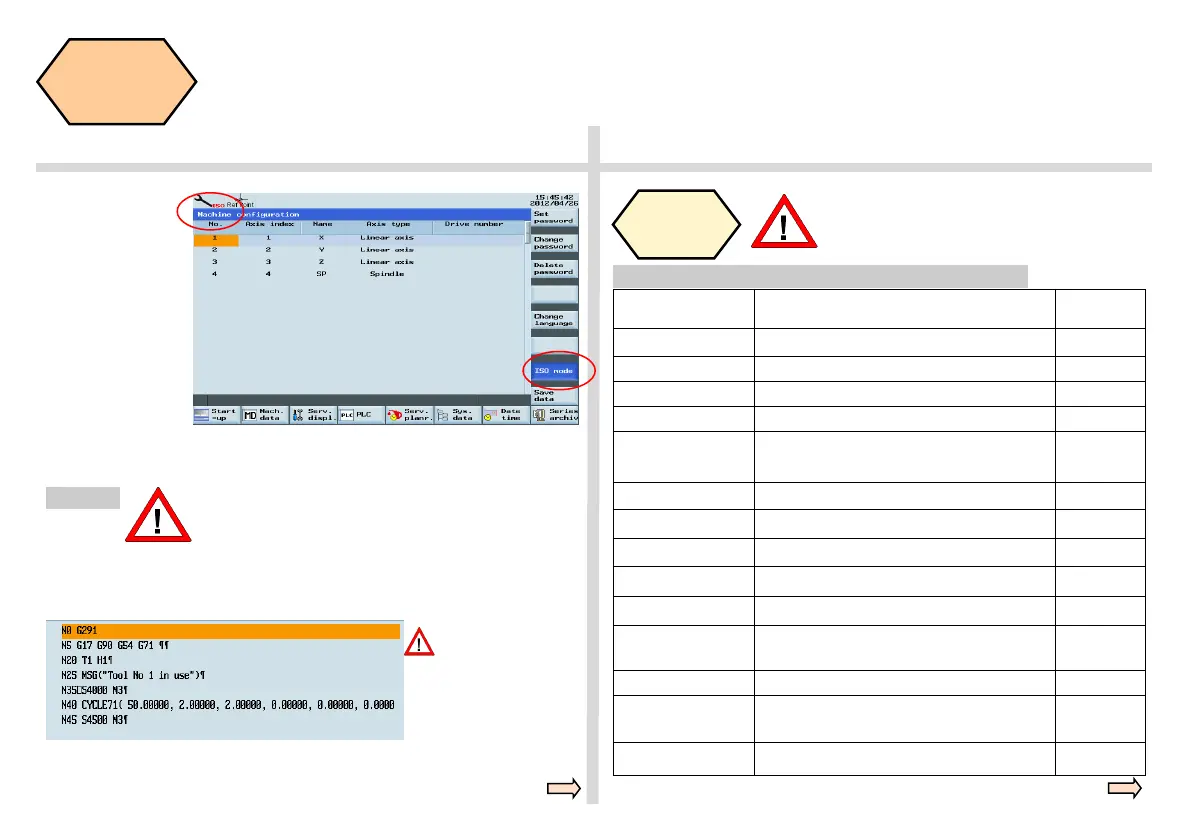

ISO code Description Compare

with DIN

G00

Orientation (rapid traverse)

As DIN

G1 Linear difference As DIN

G17/G18/G19 XY plane / ZX plane / YZ plane As DIN

G20/G21 Input in inch/mm G70/G71

G41/G42/G40 Left tool tip radius compensation / right tool tip

radius compensation / cancel tool radius

compensation

As DIN

G54 ~ G59 Select workpiece coordinate system As DIN

G80 Cancel fixed cycle

G90/G91 Absolute/incremental programming

G94/G95 Feedrate F in mm/min / mm/r As DIN

S Spindle speed As DIN

,R Reverse circle (note the form there must be

”,” before R parameter)

RND

M3/M4/M5 Spindle right / spindle left / spindle stop As DIN

M98 P _L_

Subprogram call (P+ subprogram name/ L+

times)

Program

name + L

M99

End of Subroutine M17

Brief description of typical, frequently used ISO codes

Loading...

Loading...