MCP 2400

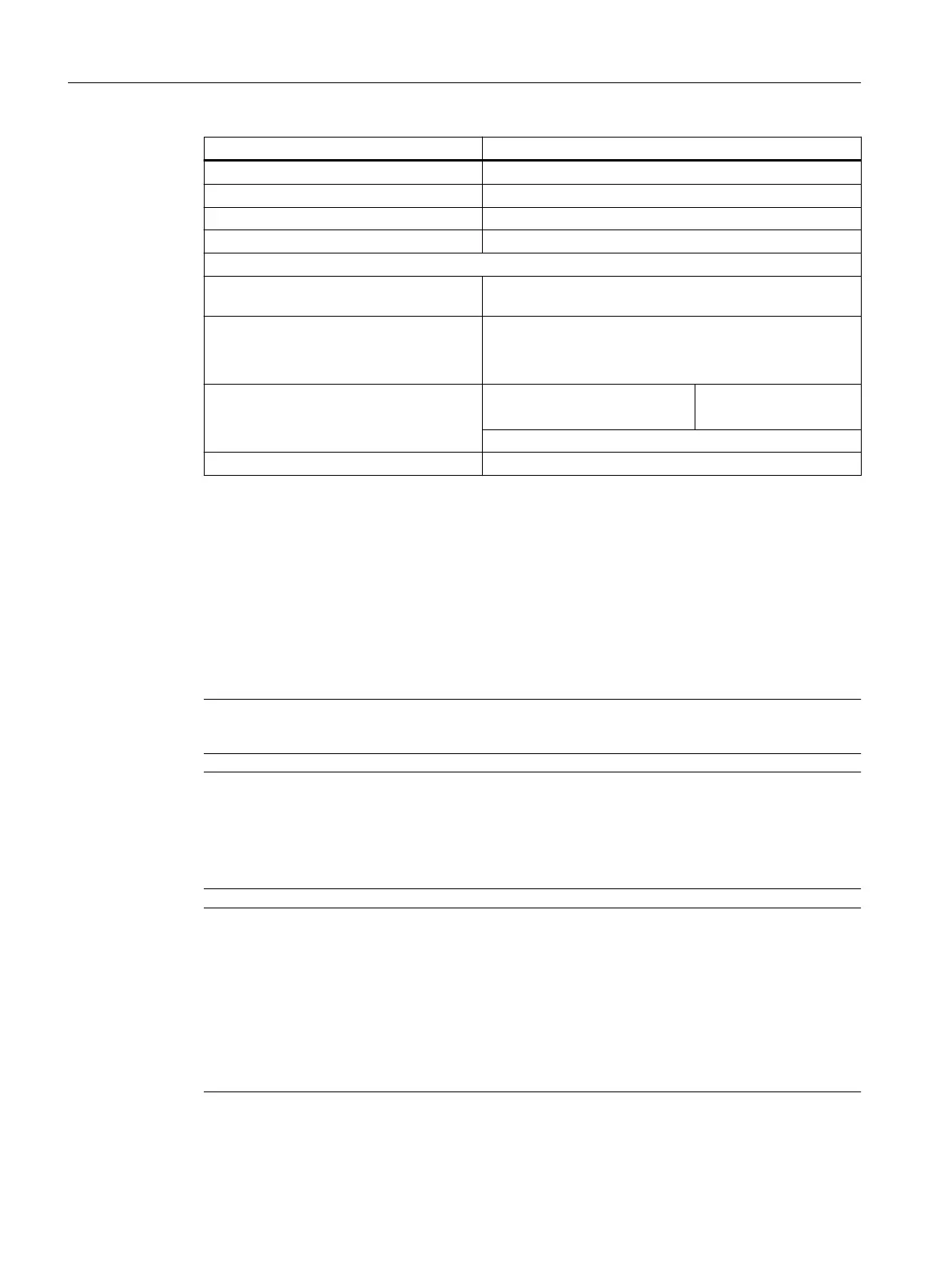

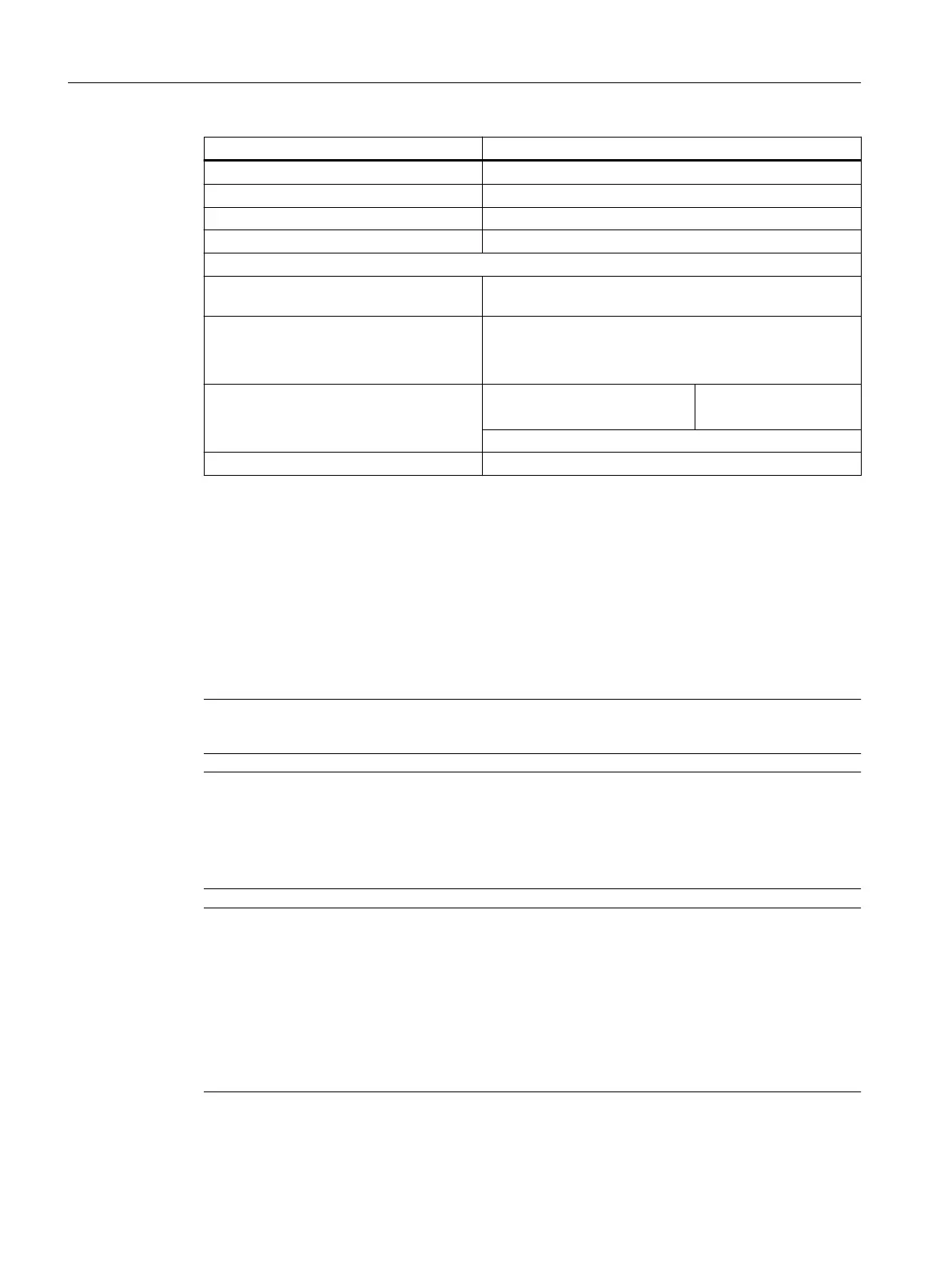

Temperature change Max. 30K/h

Relative humidity 5 ... 90% (without condensation)

Permissible change in the relative humidity Max. 6%/h

Pollution degree 2 (only use indoors)

Mechanical environmental conditions

Classication of the mechanical environ‐

ment

Class 3M2 according to EN 60721-3-3

Vibration load during operation Frequency range: 10 – 200 Hz

Deection at 9 – 18 Hz: 1.5 mm

Acceleration at 18 – 200 Hz: 2g

Shock load during operation with shock-

sensitive components

Acceleration: 5g

Shock duration: 30ms

Acceleration: 15g

Shock duration: 11ms

Load: 3 x in each direction

EMC conducted / radiation Class C2 according to EN61800-3

1) The system installer ensures the system is sealed properly according to IP65, IP classication has not been

checked by UL, UL TYPE 1.

2) Open-type equipment according to UL61010.

3) The customer must ensure that the product, with the rear cover to be attached by the customer, meets

the requirements for ame resistance of the material according to UL 94 V-1 and the mechanical stability /

re protection requirements / touch protection according to UL61010.

4) If power supply units with primary-side supplies up to 600V AC (line-to-neutral voltage) have to be

deployed, the transient voltages on the primary side of the power supply unit must be limited to 4000 V.

5) Connect the device only to a 24 V DC power supply that is compliant with protective extra-low voltage

(PELV) requirements according to UL61010.

Note

The 24 V DC power source must be adapted to the input data of the device (see "Electrical data").

Note

In a residential environment, this product can cause high-frequency interference, which may

make interference suppression measures necessary.

• Have the installation and commissioning with appropriate radio interference suppression

measures performed by qualied personnel.

Note

Damage to components by coolants and lubricants

The SINUMERIK operator components have been designed for industrial use, particularly on

machine tools and production machines. This also takes into account the use of commercially

available coolants and lubricants. The use of aggressive compounds and additives can damage

components and result in their failure.

Avoid contact between the operator components with coolants and lubricants, as resistance to

all coolants and lubricants cannot be guaranteed.

Technical data

ONE MCP Part 2: MCP 2400

24 Equipment Manual, 08/2023, A5E50324707B AB

Loading...

Loading...