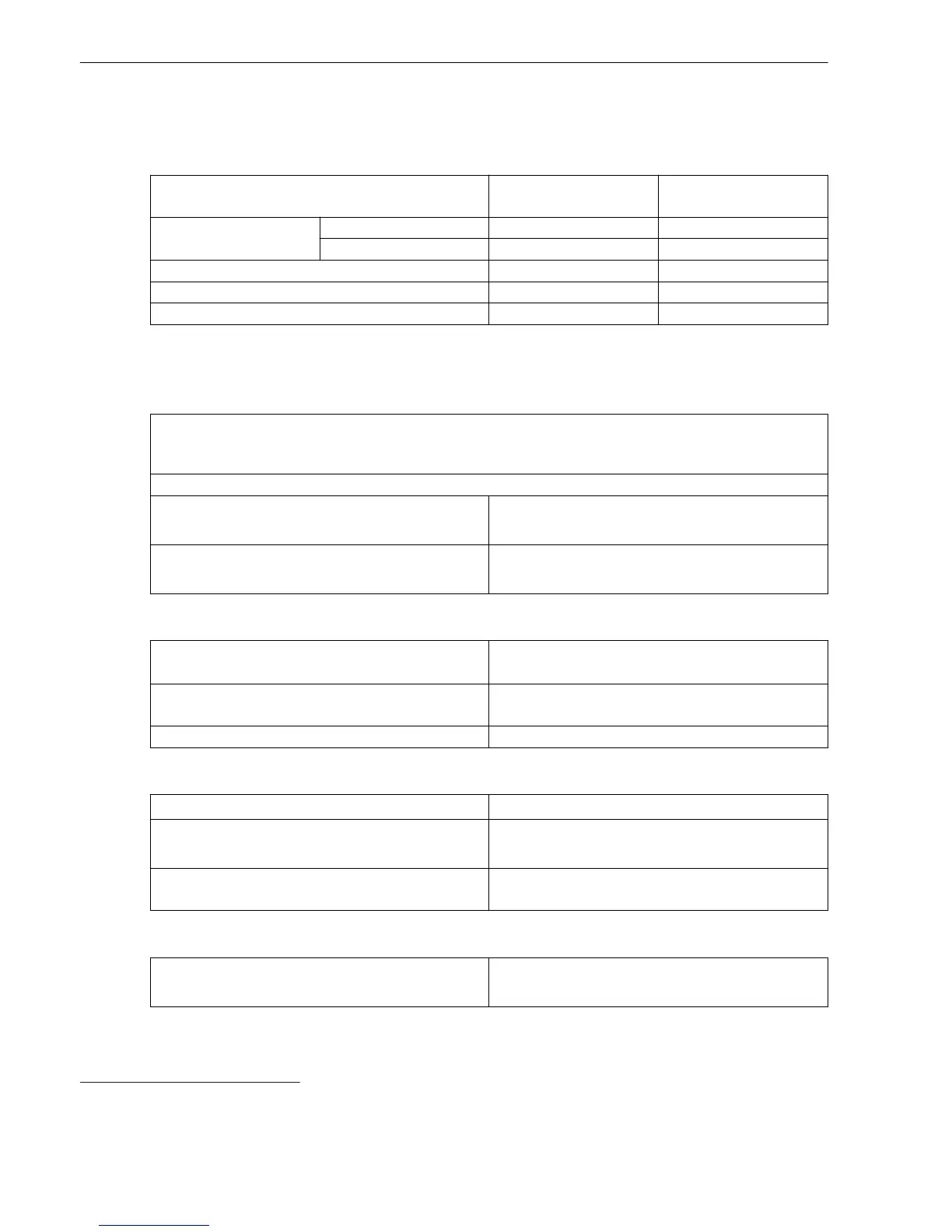

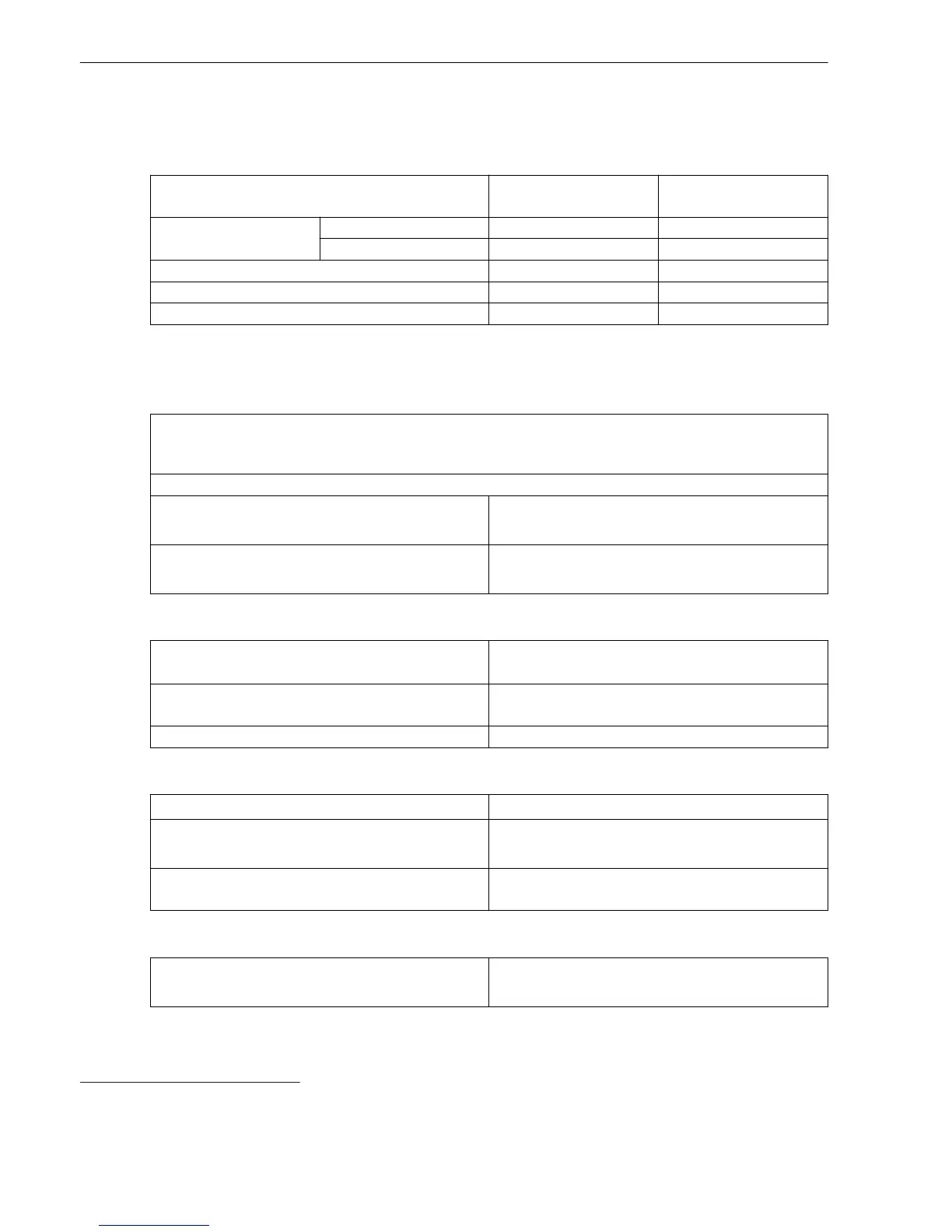

Stage with Definite-Time Characteristic Curve

Setting Values

Method of measurement Fundamental component

RMS value

–

Threshold value

20

1 A @ 100 Irated 0.030 A to 35.000 A Increments of 0.001 A

5 A @ 100 Irated 0.15 A to 175.00 A Increments of 0.01 A

Dropout ratio 0.90 to 0.99 Increments of 0.01

Time delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout delay 0.00 s to 60.00 s Increments of 0.01 s

Dropout

The greater dropout differential (= | pickup value – dropout value |) of the following 2 criteria

applies:

Dropout differential derived from the parameter Dropout ratio

If this parameter is not available, a dropout ratio of 95 % applies for overcurrent and of 105 % for undercur-

rent functionality.

Minimum absolute dropout differential

Protection-class current transformer 15 mA sec. (I

rated

= 1 A) or

75 mA sec. (I

rated

= 5 A)

Instrument current transformer 0.5 mA sec. (I

rated

= 1 A) or

2.5 mA sec. (I

rated

= 5 A)

Times

Operate time with time delay = 0 ms

Approx. 25 ms + OOT

21

at 50 Hz

Approx. 22 ms + OOT at 60 Hz

Extension of the operate time during operation with

transformer inrush-current detection

Approx. 10 ms

Dropout time Approx. 20 ms + OOT

Frequency Operating Range

0.9 ≤ f/f

rated

≤ 1.1 According to specified tolerances

10 Hz ≤ f < 0.9 f

rated

1.1 f

rated

< f ≤ 80 Hz

Slightly expanded tolerances

f < 10 Hz

f > 80 Hz

Active

Tolerances

3I0 measured via I4

22

, method of measurement =

fundamental component

1 % of the setting value or 5 mA (I

rated

= 1 A)

or 25 mA (I

rated

= 5 A), (f

rated

± 10 %)

11.17

20

If you have selected the method of measurement = RMS value, do not set the threshold value under 0.1 l

rated,sec

.

21

OOT (Output Operating Time) additional delay of the output medium used, see Chapter 11.1.4 Relay Outputs

22

Slightly expanded tolerances will occur during the calculation of 3I0, maximum factor of 2

Technical Data

11.17 Stage with Definite-Time Characteristic Curve

588 SIPROTEC 5, Low-Impedance Busbar Protection 7SS85, Manual

C53000-G5040-C019-6, Edition 06.2016

Loading...

Loading...