SIRIUS 3RU2/3RB3 overload relays

5.5 Configuration

SIRIUS Innovations

504 System Manual, 01/2011, A8E56203870002-03

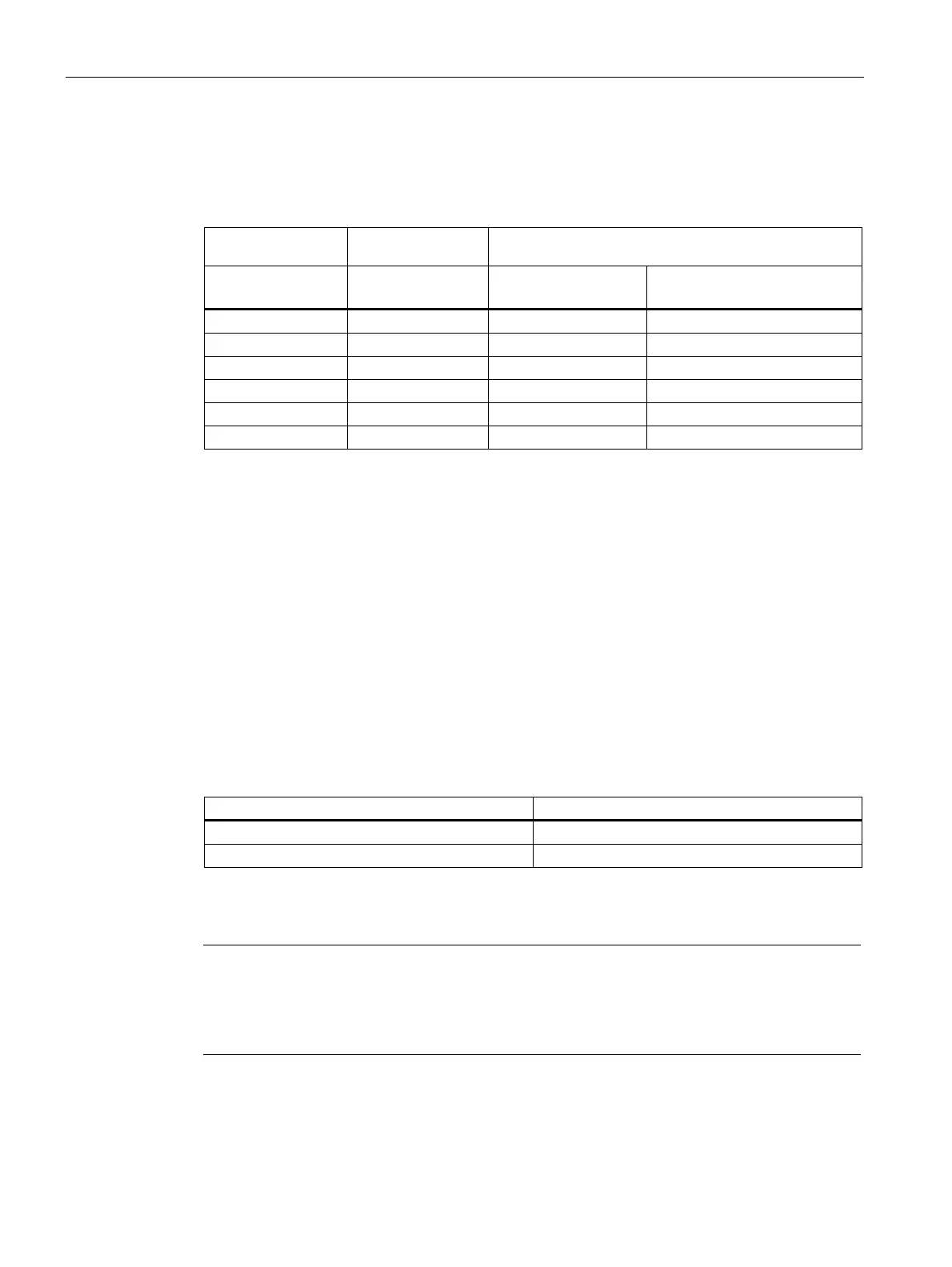

Appropriate contactors are required to protect loads. The table below provides an overview

of the assignments between overload relays and contactors, along with their power ratings.

Table 5- 9 Overload relay with contactor assemblies

Overload relay Current range Contactors

(type, size, rating in kW)

Type [A] 3RT201

S00 3/4/5.5/7.5

3RT202

S0 5.5/7.5/11/15 /18.5

3RU211

1)

0.11 … 16 ✓ -

3RU212

1)

1.8 … 40 - ✓

3RB301

1)

0.1 … 16 ✓ -

3RB302

1)

0.1 … 40 - ✓

3RB311

1)

0.1 … 16 ✓ -

3RB312

1)

0.1 … 40 - ✓

1)

If you are using the overload relays in feeders, see Technical data (Page 536)

The configuration guide titled "Configuring SIRIUS Innovations - Selection data for load

feeders in fuseless and fused designs" (order no. 3ZX1012-0RA21-1AC0) provides

information about the assembly of type-tested motor feeders according to IEC/EN 60947-4-1

with type of coordination 1 or 2.

5.5.1.2 Normal and heavy-duty starting

Normal starting

Selecting the right overload relay means considering the start time as well as the rated motor

current. The start time refers to the time required by the motor between switching on and

reaching its rated speed.

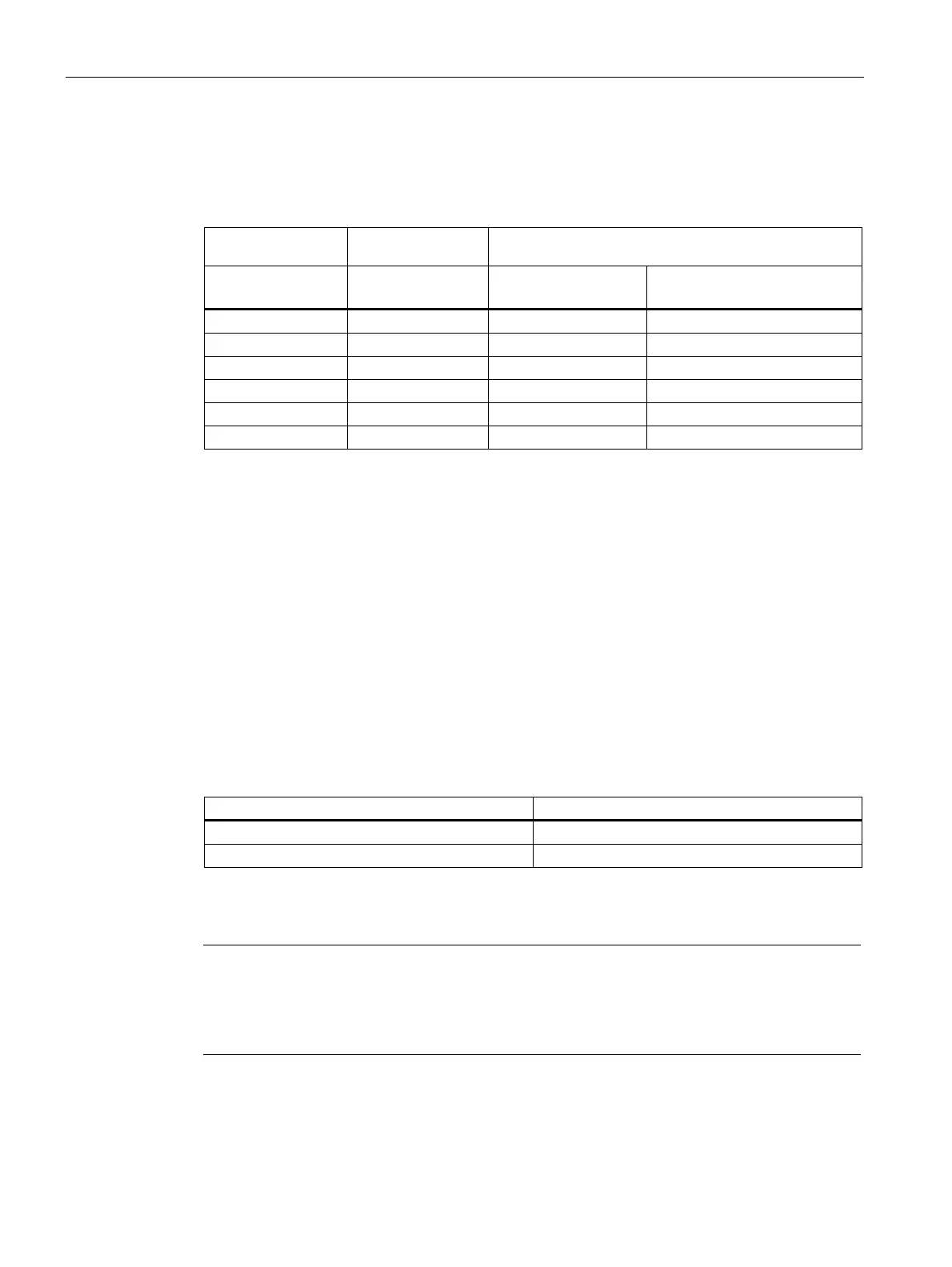

Table 5- 10 Normal starting

Designation Start time

Normal starting < 10 s

Heavy-duty starting > 10 s

Heavy-duty starting

Note

Special overload relays with corresponding tripping classes are required to protect heavy-

duty-starting motors (for the acceleration of large centrifuges, for example). In the case of

heavy-duty starting, the cables and contactors also have to be dimensioned specifically on

account of the increasing thermal load.

Loading...

Loading...