to the wood rail mounts - be sure to maintain the 1/16” - 3/32”

spinner backplate clearance. Use medium fuel tubing (not

supplied) to make the required connections between the engine

and fuel tank and the vent line and the muffler manifold pressure

nipple.

The throttle linkage will be made during the radio installation

phase of these instructions. This completes the engine and fuel

tank installation.

SPINNER ASSEMBLY:

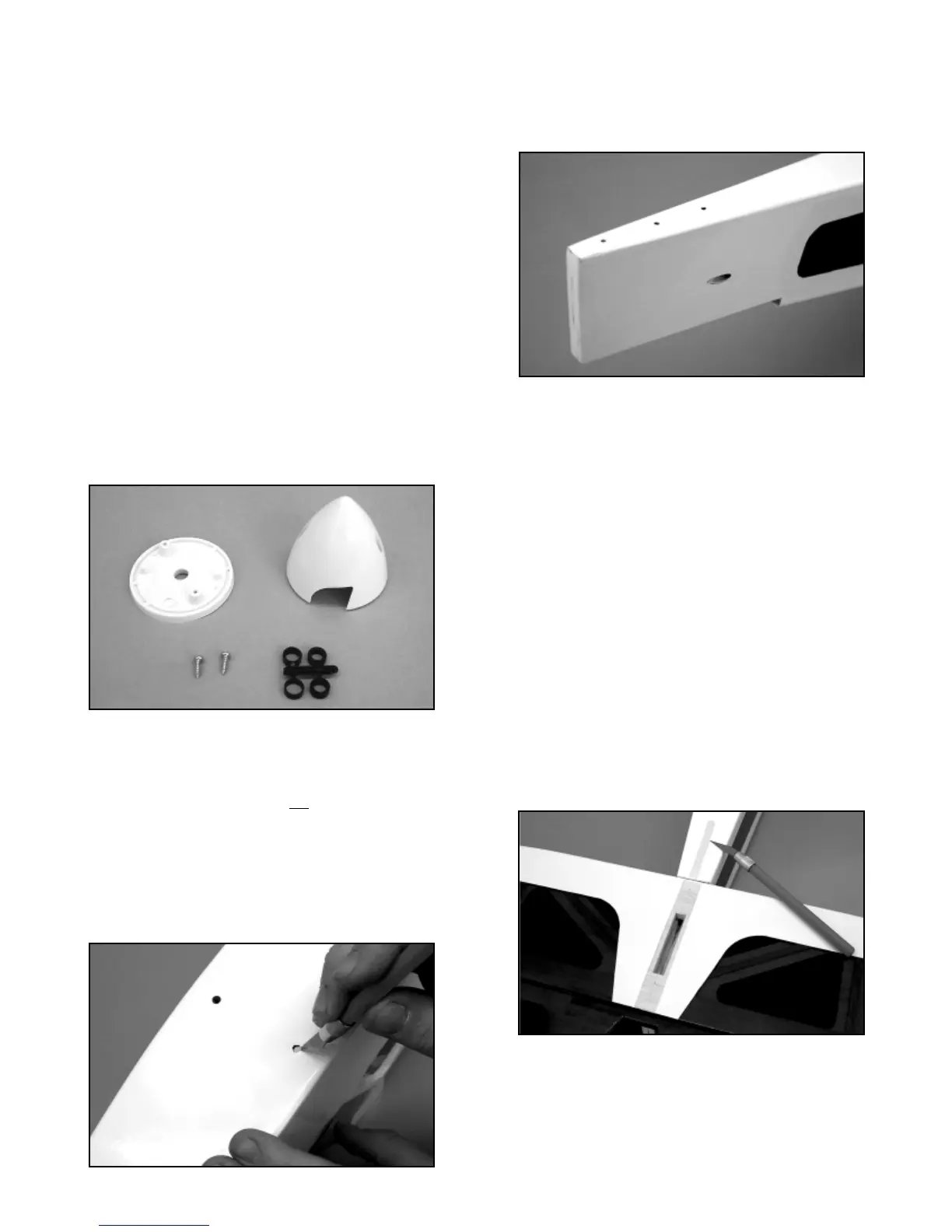

Locate the white SIG spinner assembly from the kit contents. This

spinner is easy to install, lends a great look to your finished

RASCAL FORTY ARF and is ready to use with typical APC

propellers for engines in the size range for this model!

Start by choosing the correct adapter ring for your particular

engine. The fit should be firm (not loose) over the engine’s prop

shaft. Slip the spinner backplate onto the prop shaft and onto the

adapter ring. The propeller is installed next using the engine’s

washer and nut to secure it. The spinner cone is now installed over

the prop and into the recess in the backplate. The spinner is then

secured in place using the provided screws. Be sure to snug these

screws firmly in place but do not over-tighten them.

FUSELAGE AND TAIL GROUP ASSEMBLY:

Note that the elevators have been pre-hinged to the horizontal

stabilizer. Flex the elevators up and down a few times to free their

movement. However, the rudder has not

been pre-hinged and will

have to be hinged during the following assembly steps.

❑ 1) The fuselage has been built and covered with a few

openings that now need to be opened up and cleared to complete

assembly. These are the two landing gear bolt holes on the bottom

of the fuselage and the three pre-drilled holes for mounting the

tailwheel assembly, at the bottom rear of the fuselage.

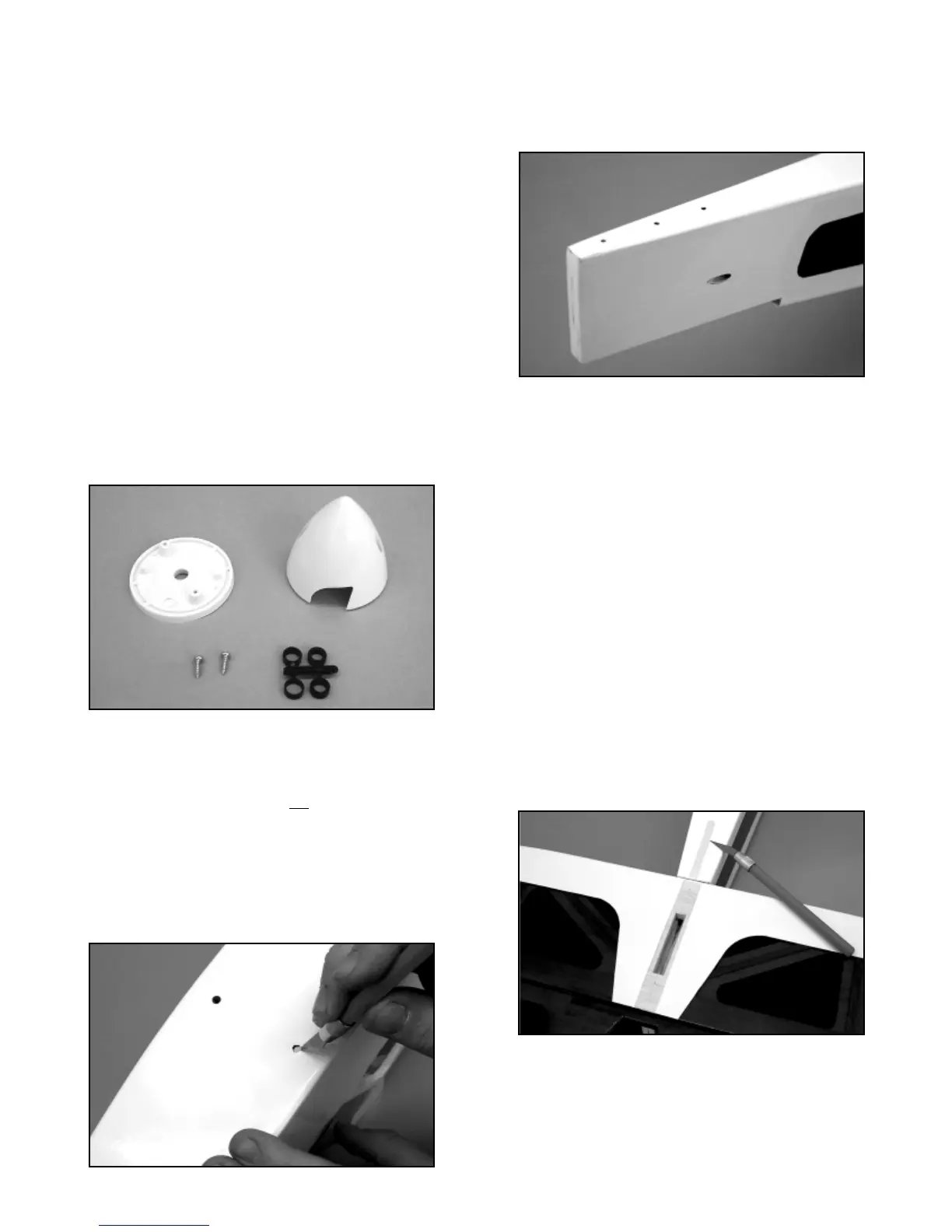

Last, you will need to remove the covering over the rudder and

elevator pushrod exits. These are located on each side of the

fuselage, beneath the horizontal stabilizer. A sharp #11 blade is

perfect for this step. If necessary, use a covering iron to re-seal the

covering around these openings.

❑ 2) From the kit contents, locate the horizontal stabilizer and

elevator set and the vertical fin and rudder set. Join the wing

panels together and bolt the wing to the fuselage. Set the airplane

on a flat surface that allows you to easily view it from both the

front and rear. Use 5-minute epoxy to glue the horizontal

stabilizer/elevator assembly to the fuselage. Apply glue liberally to

the stabilizer saddle at the top rear of the fuselage. Also apply

glue to the bottom of the stabilizer where it contacts the fuselage.

Carefully center the stabilizer to the fuselage, making sure it is

centered in top view as well as in front and rear view. Use weights

or pins to hold the stabilizer in this aligned position until the epoxy

cures. Wipe off any excess glue with alcohol.

❑ 3) Remove the rudder from the vertical fin, including the three

hinges. The rudder will be hinged later. The vertical fin is now

glued in place to the top of the stabilizer. Begin by trial-fitting the

fin into the slot on the top of the stabilizer. Test the fit, making sure

that the bottom of the fin sits flat and in full contact to the stabilizer.

Trim or sand the bottom of the fin tab until the fin sits fully in place

on top of the stabilizer. Holding the fin in place, use a sharp pencil

to trace around its forward bottom fairing, where it extends forward

of the stabilizer and on to the top of the fuselage. Remove the fin

and use a sharp knife to remove the covering from just inside of

the pencil marks just made.

Use 5-minute epoxy to apply glue to the bottom of the vertical fin,

including the tab that fits into the top of the stabilizer. Press the fin

in place into the top of the stabilizer slot and wipe off any excess

glue with alcohol. Use strips of tape and/or pins to align the fin at

90

O

to the stabilizer. View the airplane from the front, making sure

the fin is perfectly upright and aligned to the stabilizer, wing, and

fuselage without tilting one way or the other. With the fin now held

12

Loading...

Loading...