6

PNEUMATIC INFORMATION

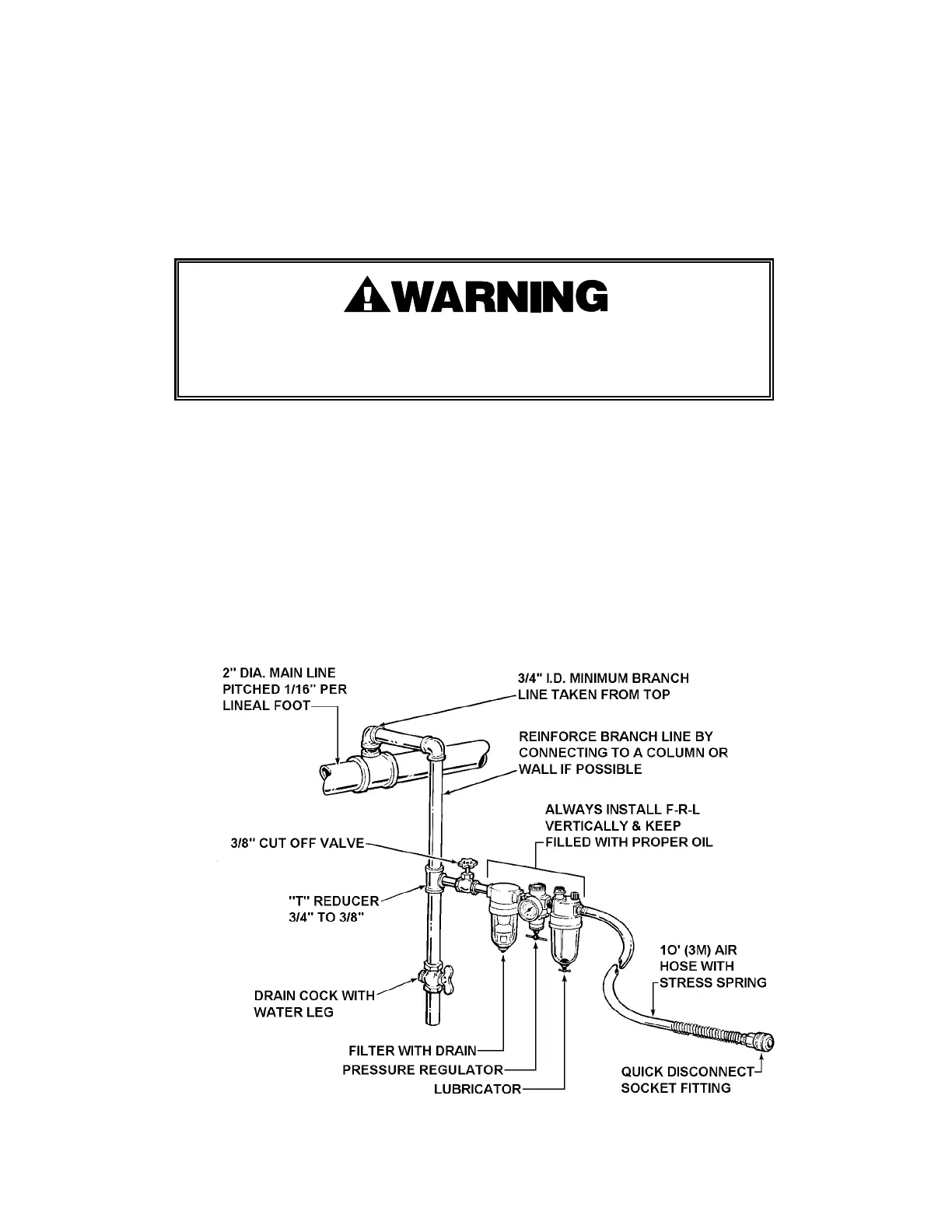

Air Supply Installation

If the compressor has a good dryer unit, use black pickled pipe. When a dryer unit is not

installed, use galvanized or copper pipe.

To preform reliably, a pneumatic tool requires a continuous source of clean, water-free air at

adequate pressure.

Never operate this tool using a bottled air or gas source.

Bottled air/gas sources do not provide consistent operating pressure and

could result in air pressures that exceed the maximum allowed for the tool.

A filter-regulated-lubricator unit (Signode Part No. 008559) must be installed as close to the air

tool as possible, preferably within 10 feet. It should be placed in a convenient location where it

can easily be drained, adjusted, and filled with oil. The air hose must have at least a 3/8" I.D.. A

quick-connect press-on socket is installed on the stress spring end of the hose for convenient

hookup to the air tool.

Filter and lubricator bowls are made of polycarbonate material. Do not install where bowls may

be exposed to materials incompatible with poly carbonate. Certain oils, solvents, and chemicals

or their fumes can weaken these bowls and possibly cause them to burst. Clean only with warm

water. A cut-off valve placed ahead of the filter will be useful when cleaning the filter or

replenishing the lubricator.

Loading...

Loading...