AP04 Datum 08.06.2011 Art.Nr. 84211 Änd. Stand 189/11 7

User Information

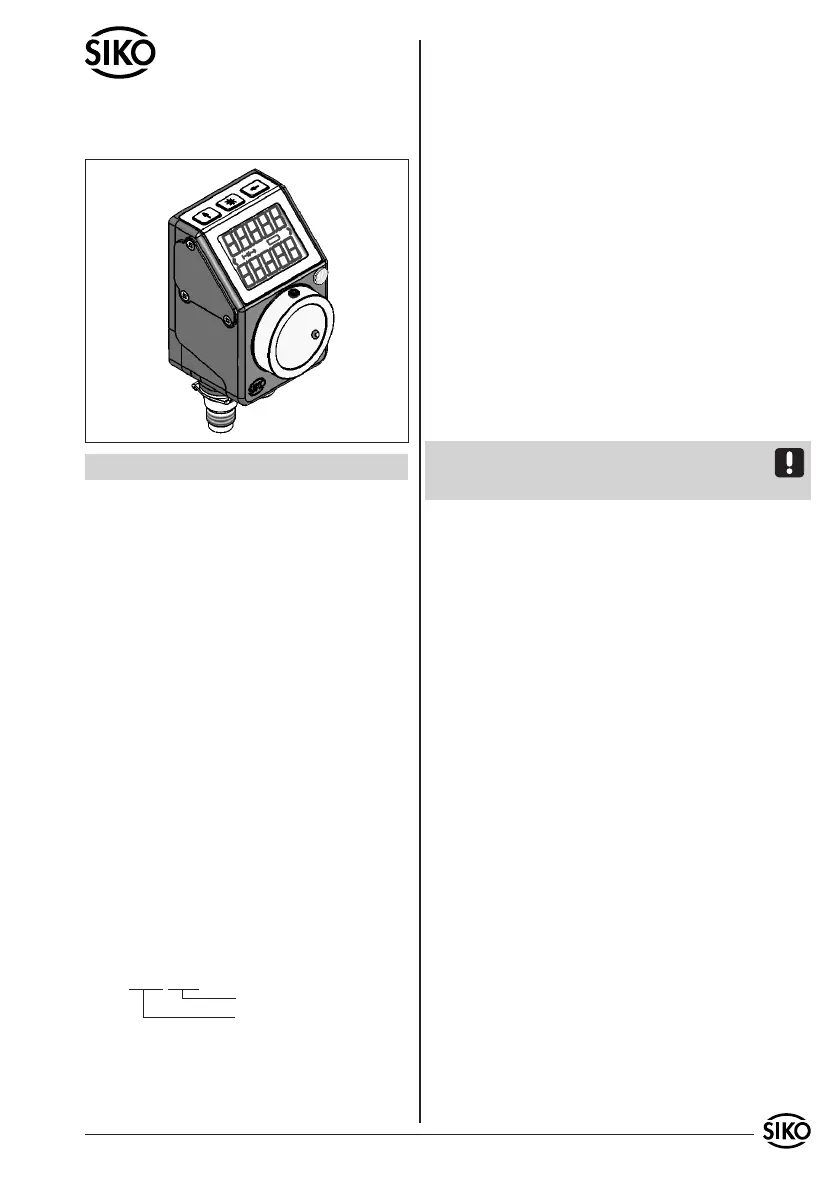

AP04

Absolute/Electronic Positon Indicator

ENGLISH

1. Warranty information

• In order to carry out installation correctly, we

strongly recommend this document is read very

carefully. This will ensure your own safety and the

operating reliability of the device.

• Your device has been quality controlled, tested

and is ready for use. Please respect all warnings

and information which are marked either directly

on the device or in this document.

• Warranty can only be claimed for components sup-

plied by SIKO GmbH. If the system is used together

with other products, the warranty for the complete

system is invalid.

• Repairs should be carried out only at our works.

If any information is missing or unclear, please

contact the SIKO sales sta.

2. Identification

Please check particular type of unit and type

number from the identification plate.Type number

and the corresponding version are indicated in the

delivery documentation.

e. g. AP04-0023

version number

type of unit

3. Intended use

The AP04 position indicator is a high-precision

measuring instrument. It serves exclusively for the

acquisition and output of position values, for pro-

cessing and providing measured values as electrical

output signals for an upstream control as well as

for the indication of target values and positioning

aids. The AP04 must be used exclusively for these

applications.

• Conversion or alteration of the device not approved

by SIKO is forbidden for safety reasons.

• Observe the operation and installation instructions

specified in this User Information.

• Refrain from any operation that may compromise

safety with the device.

4. Installation

The unit should be used only according to the pro-

tection level provided. Protect the unit, if necessa-

ry, against environmental influences such as spra-

yed water, dust, knocks, extreme temperatures.

Attention: The unit should not be exposed to elec-

tromagnetic fields. Especially do not mount close to

adhesive or other permanent magnets.

Before mounting the AP04, the enclosed self-adhe-

sive gasket (microcelluar rubber) must be stuck on

the bearing support or distance plate, respectively.

This helps to level possible unevenness and pre-

vents dust from invading the bearing.

Slide AP04 onto the solid shaft, insert torque pin

into the prebored mounting hole and use grub

screw M3 to fix the AP04's hollow shaft to the

machine's solid shaft (see fig. 1).

Please note: Do not tighten the grub screws with

more than 0,2 Nm!

• Ensure sliding fit between solid shaft and AP04.

• Ensure accurate shaft alignment and mount the

AP04 without force. Do not exceed the values

for the maximum axial and radial shaft load. If

the shaft is not correctly aligned, strain on the

bearings will result, which may cause overheating

and irreparable damage.

• Ensure that AP04 does not jam and that it is moun-

ted without strain.

• Knocks on the unit should be avoided!

Loading...

Loading...