5

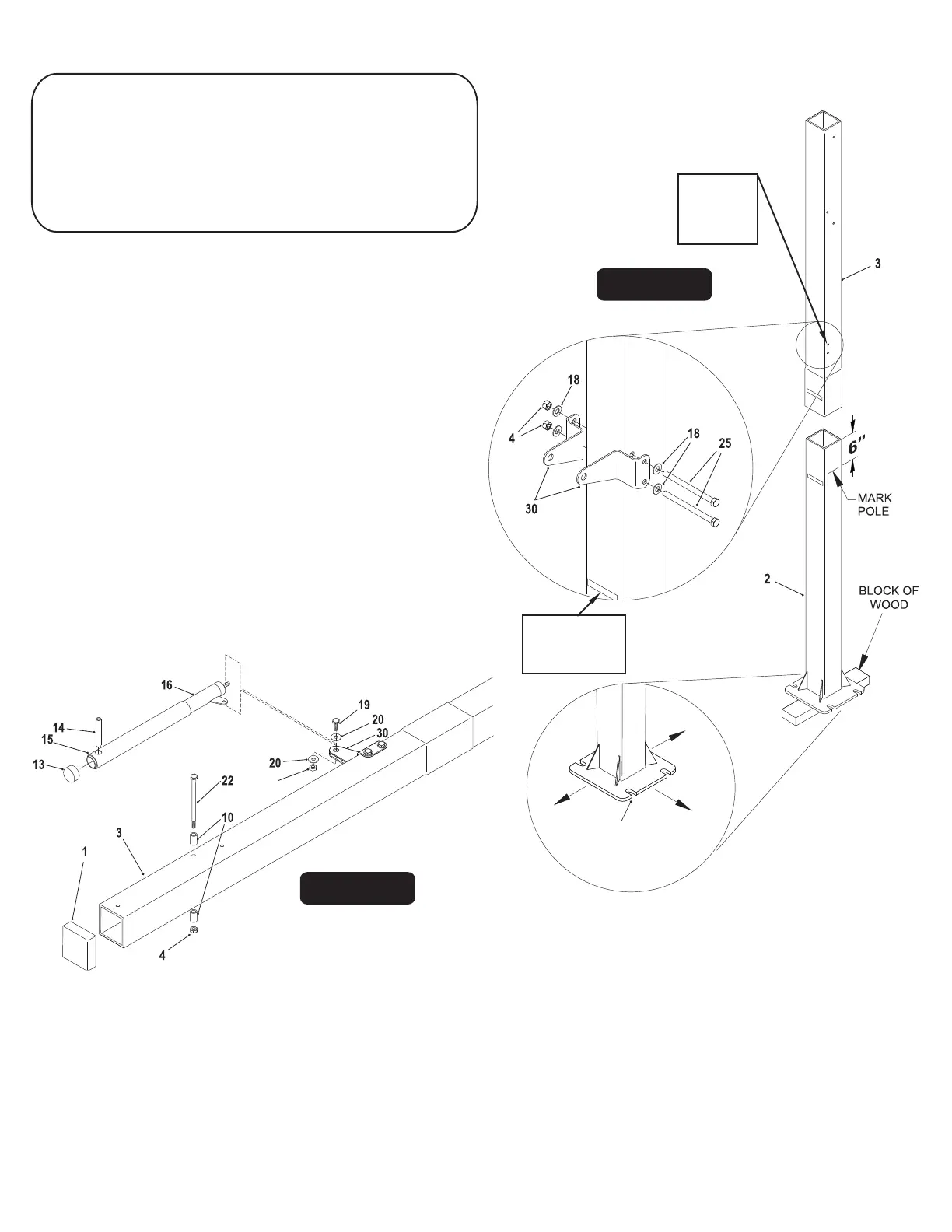

Figure 3

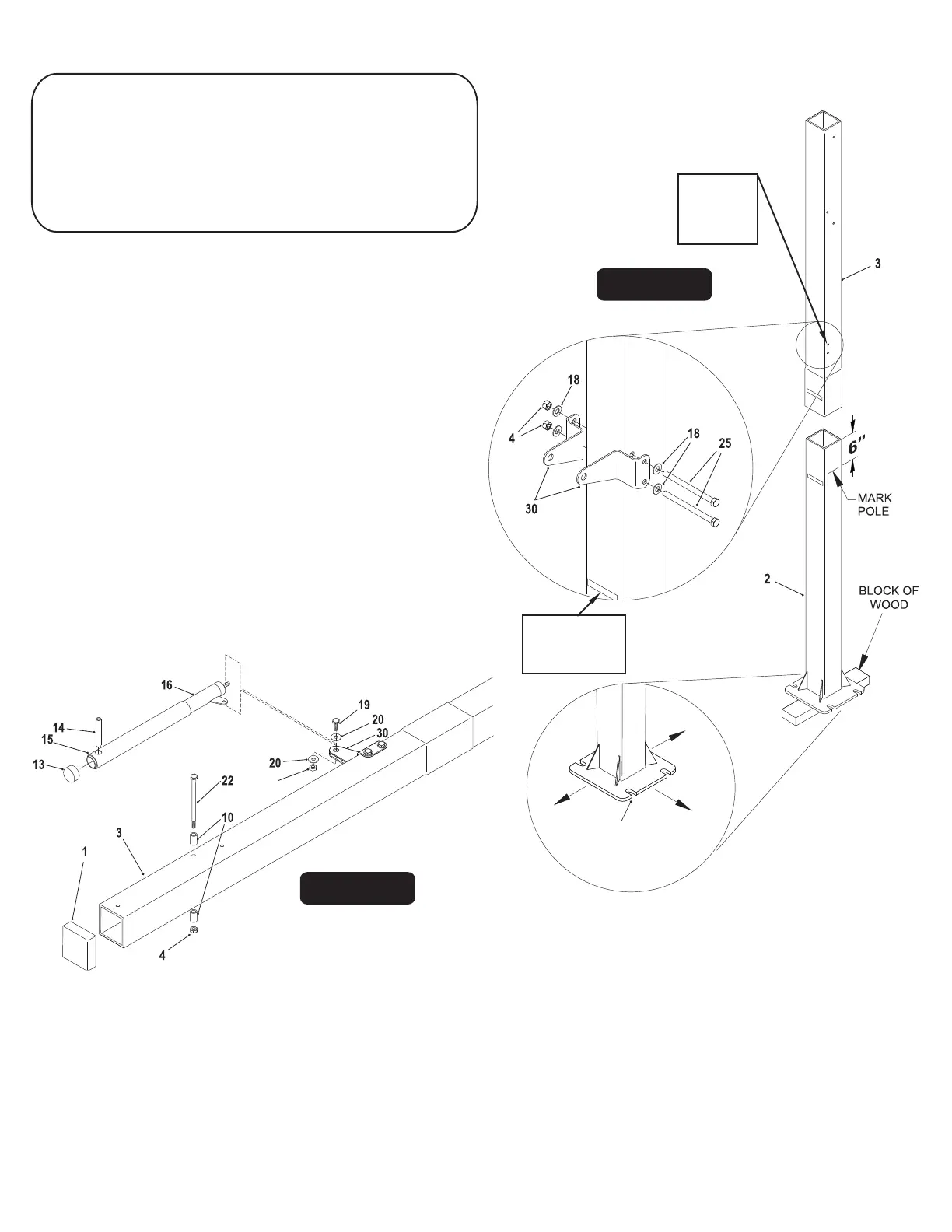

6.

7. Secure two stop spacers (#10) to pole, as shown in Figure

4, using one hex bolt (#22) and one lock nut (#4).

NOTCHES IN BASE

PLATE MUST BE ON

SIDE AS SHOWN

FRONT

BACK

SIDE

5. Lay Pole Assembly on its side on two padded saw horses. Slide

tab on Actuator (#16) between Post Ears (#30) and secure

using one bolt (#19), two washers (#20) and one lock nut

(#4). See Figure 4. Tighten bolts tight.

Figure 4

21

SILVERBACK ASSEMBLY INSTRUCTIONS (Day 5)

3. Attach Post Ears (#30) to holes near the bottom of Top

Post (#3) using two hex bolts (#25) four washers (#18)

and two lock nuts (#4). See Figure 3.

TOOLS REQUIRED FOR THE FOLLOWING STEPS

1 - 15/16" Open end Wrench

1 - 15/16” Socket and Ratchet (optional)

1 - 9/16” Deep Well Socket & Ratchet

1 - 3/4” Socket & Ratchet

1 - 3/4” Open end Wrench

1 - Phillips Screwdriver

1 - Level

1 - Tape Measure

1 - Rubber Mallet

1 - Set of Padded

Saw Horses

4.

Note: If necessary, use a rubber mallet to tap in

Pivot Tube (#14)

1 - 9/16” Open end Wrench

1 - Pair of Safety Glasses

Be sure that

the holes are

toward the

back of the

pole.

IMPORTANT! Nylon washers (#5) adequately space

painted parts at all pivot points. Neglecting the use of

these washers will result in rusted parts.

NOTE: All board arms are made of rectangular tubing.

Tightening hardware too tight may damage tubing

and make adjustment of system difficult.

1.

2.

Align the upper pole (#3) with the bottom pole (#2) as

shown in Figure 3 and slide them together. Stand poles up

on a block of wood, lift poles up and hit on a block of

wood until the bottom of the upper pole reaches the 6”

mark on the bottom pole. Hit poles a minimum of 7 times.

This is a friction-locking joint and requires no hardware.

IMPORTANT! DO NOT hit poles with hammer or

sledge hammer to slide poles together.

Place Pole Cap (#1) onto top of Top P

ole (#3). Note: Pole

Cap may be pre-installed by the factory.

Slide Actuator Sleeve (#15) over Actuator (#16) and place

Actuator Cap (#13) on top. Slide Pivot Tube (#14) through hole

near top of Actuator & Actuator Sleeve until equal amounts

stick out through both sides of Actuator. See Figure 4.

BAC SIDE

K

BACK SIDE

CBA

K SIDE

Match up both

“Back Side”

stickers on the

back of the poles.

Before putting any of the poles tubes together, mark bottom

pole (#2) 6 inches from the top end. Be sure to match up

both “Back Side” stickers on the back of the poles

and that the holes on top pole are toward the back.

See Figure 3.

Loading...

Loading...