23

2.1 BOILER ROOM

The boiler room should feature all the

characteristics required by standards

governing liquid fuel heating systems.

2.2

BOILER ROOM DIMENSIONS

Position the boiler body on the founda-

tion bed, which should be at least 10

cm high. The body should rest on a

surface allowing shifting, possibly by

means of sheet metal.

Leave a clearance between the boiler

and the wall of at least 0.60 m, and

between the top of the casing and the

ceiling of 1 m (0.50 m in the case of

boilers with incorporated D.H.W. tank).

The ceiling height of the boiler room

should be less than 2.5 m.

2.3 CONNECTING UP SYSTEM

When connecting up the water supply

to the boiler, make sure that the speci-

fications given in fig. 1 are observed.

All connecting unions should be easy

to disconnect by means of tightening

rings.

A closed expansion tank system

must be used.

2.3.1 Filling the water system

Before connecting the boiler, thorou-

ghly flush the system to eliminate

scale which could damage the

appliance.

Filling must be done slowly so as to allow

any air bubbles to be bled off through the

air valves. In closed-circuit heating

systems, the cold water filling pressure

and the pre-charging pressure of the

expansion vessel should be no less than

or equal to the height of the water head

of the installation (e.g. for water head of

5 metres, the vessel pre-charging pres-

sure and installation filling pressure

should be at least 0.5 bar).

2.3.2

Water system characteristics

THE WATER USED FOR THE CENTRAL

HEATING SYSTEM SHOULD BE TREA-

TED IN THE FOLLOWING CASES:

– for extensive systems (with high

contents of water);

– frequent addition of water into the

system;

– should it be necessary to empty the

system either partially or totally.

2.4 CONNECTING UP FLUE

The flue is of fundamental importance

for the proper operation of the boiler;

if not installed in compliance with the

standards, starting the boiler will be

difficult and there will be a consequent

formation of soot, condensate and

encrustation.

The flue used to expel combustion pro-

ducts into the atmosphere must meet

the following requirements:

–

be constructed with waterproof

materials, and resistant to smoke

temperature and condensate;

– be of adequate mechanical resilien-

ce and of low heat conductivity;

– be perfectly sealed to prevent coo-

ling of the flue itself;

– be as vertical as possible; the termi-

nal section of the flue must be fitted

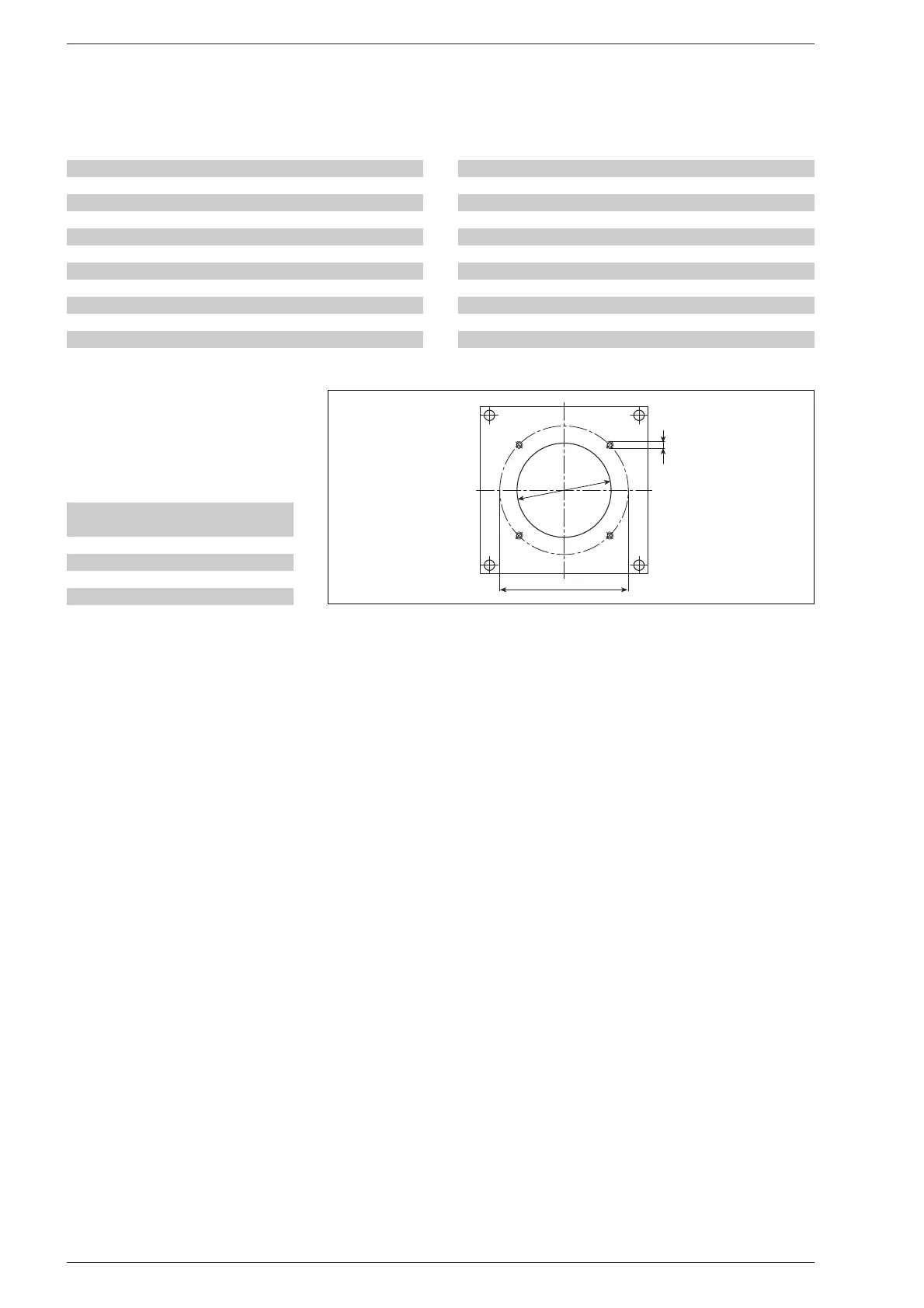

1.6.4 Burner assembly

The boiler is supplied to be assembled

on the burner.

The connection flange dimensions are

indicated in fig. 4.

2 INSTALLATION

A B C

mm mm ø

1R 4÷6 110 150 M8

1R 7÷9 130 170 M8

2R 6-7 130 170 M8

2R 8÷15 160 190 M10

1.6.3 F.B.R. burners

Boiler Model Atomising angle

1R4 G1 2001 60°

1R5 G1 2001 60°

1R6 G2 2001 60°

1R7 G2 2001 60°

1R8 G2 2001 60°

1R9 G2 MAXI 60°

Boiler Model Atomising angle

2R6 G2 MAXI 60°

2R7 FG 14 TC 60°

2R8 FG 14 TC 60°

2R9 G 20 TC 60°

2R10 G 20 TC 60°

2R11 G 20 TC 60°

2R12 G 20 TC 60°

2R13 G 20 TC 60°

2R14 G 30/2 TC 60° - 45°

2R15 G 30/2 TC 60° - 45°

Loading...

Loading...