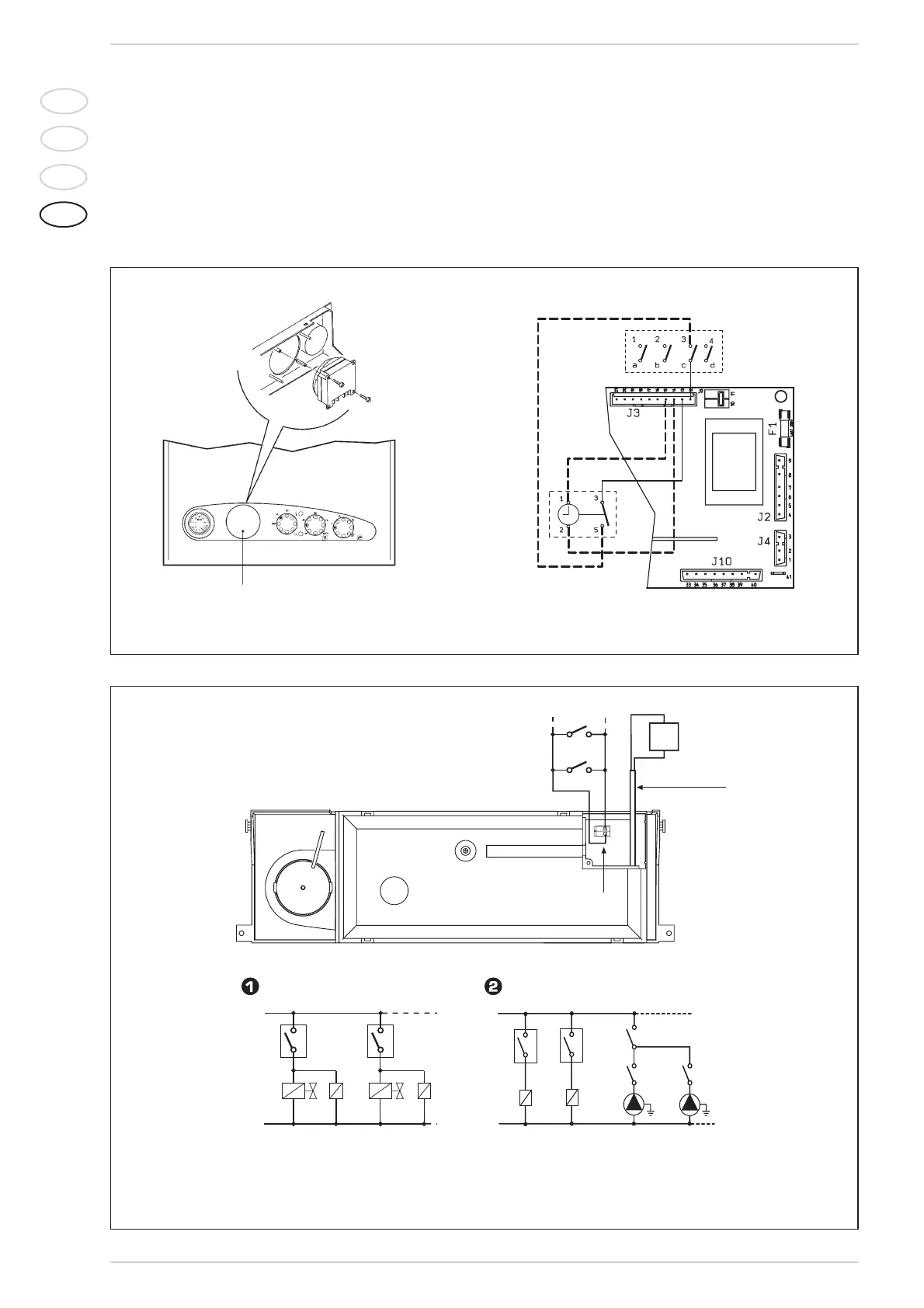

the positioning and, with the panel open, fix

the clock to the panel with the screws spe-

cifically supplied.

Remove the faston that connects terminal

3 of the rotary switch and insert it in termi-

nal 3 of the clock.

Complete the connection of the electric

clock as indicated in the diagram.

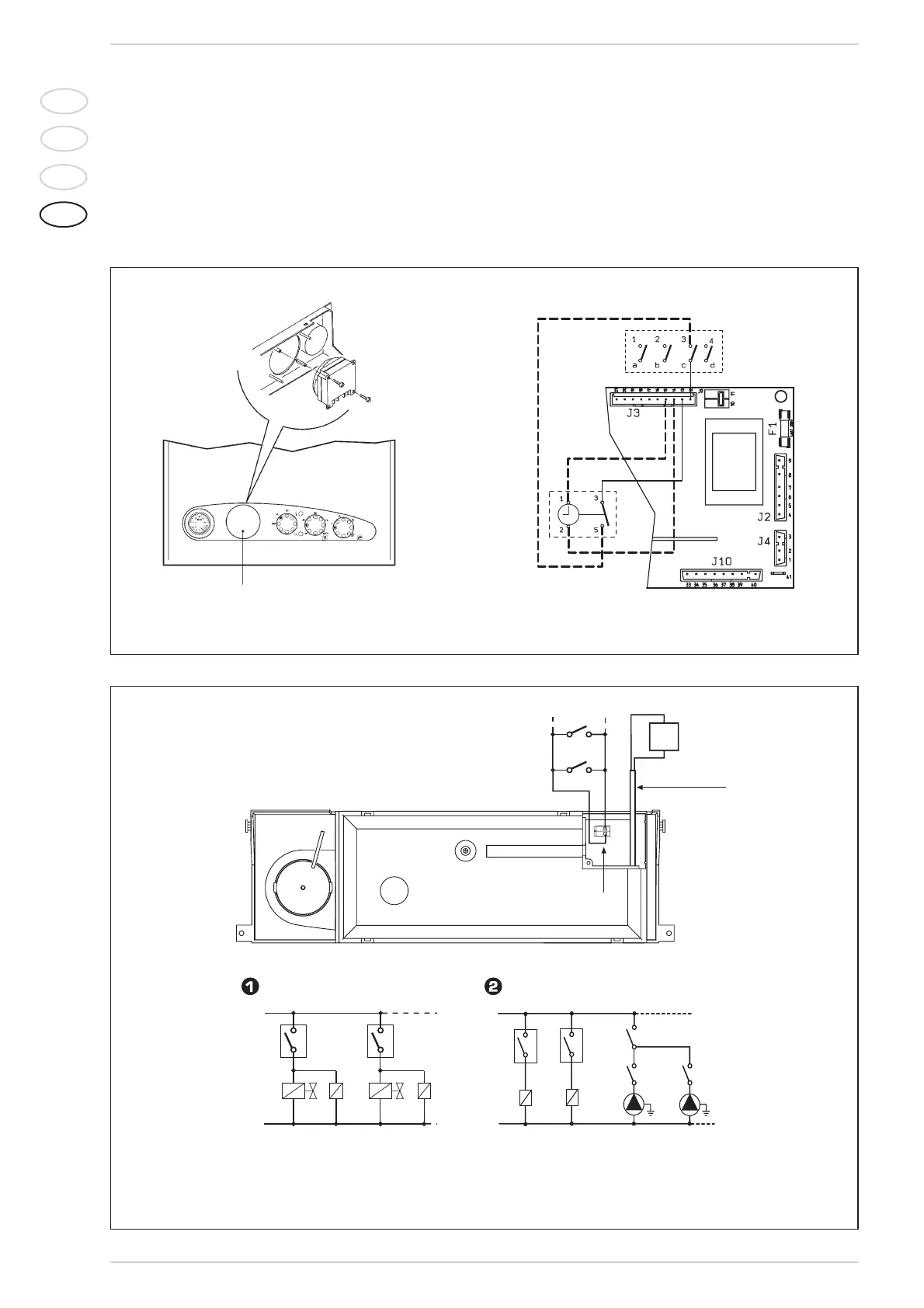

3.9 ELECTRICAL

CONNECTION

ZONE SYSTEMS

Use a separate electric line to link up the

room stats and relative zone valves or

pumps.

The connection of the micros or the

relay contacts is carried out on termi-

nals 10-11 of the “TA” connector of elec-

tronic panel after having removed the

existing bridge (fig. 25).

88

IT

ES

PT

GB

KEY

OP Time programmer

C Rotary switch

Fig. 24

REMOVE

L

N

TA

TA

1

VZ

R

VZ1

R1

CIRCUITO CON VALVOLE DI ZONA

NOTA: I relé vengono impiegati solo nel caso

le valvole di zona siano prive di micro.

CIRCUITO CON POMPE DI ZONA

CR1

CR

Connettore "TA"

10 11

RL

Cavo

pompa

impianto

NOTA: Sostituire la pompa impianto della

caldaia con il tronchetto optional cod. 8094001.

Collegare il cavo della pompa impianto ad un

relè di potenza (RL).

L

N

TA1

CRL

R1

P

TA

R

P1

CR

CR1

LEYENDA

TA-TA1 Zone room stat

VZ-VZ1 Zone valve

R-R1 Zone relay

CR-CR1 Relay contact or micro zone valve

P-P1 Zone pump

RL Power relay

CRL Power relay contact

Pump cable

“TA” connector

CIRCUIT WITH ZONE VALVES CIRCUIT WITH ZONE PUMPS

NOTE: Relays are used only if the area

valves have no microswitches.

NOTE: Replace the heating pump with the option-

al stub pipe, code 8094001. Connect the pump

cable to a power relay (RL).

Fig. 25

Loading...

Loading...