4.1 D.H.W. PRODUCTION

The preparation of hot water is guaranteed

by the tank unit in glass enamelled steel

with magnesium anode for the protection of

the tank unit and inspection flange for its

control and cleaning.

The magnesium anode must be checked

annually and substituted when it is worn.

If the boiler does not produce hot water,

make sure that the air has been released

by pressing on the manual outlets after

having switched off the main switch.

4.2 ADJUSTMENT OF HEAT OUTPUT

FOR C.H. MODE

To adjust boiler heat output for heating pur-

poses, i.e., modifying the setting made at the

factory which is approximately 19 kW, use a

screwdriver to adjust the C.H. heat output

trimmer (1 fig. 22).

To increase working pressure, turn the trim-

mer clockwise; to reduce pressure, turn the

trimmer counterclockwise.

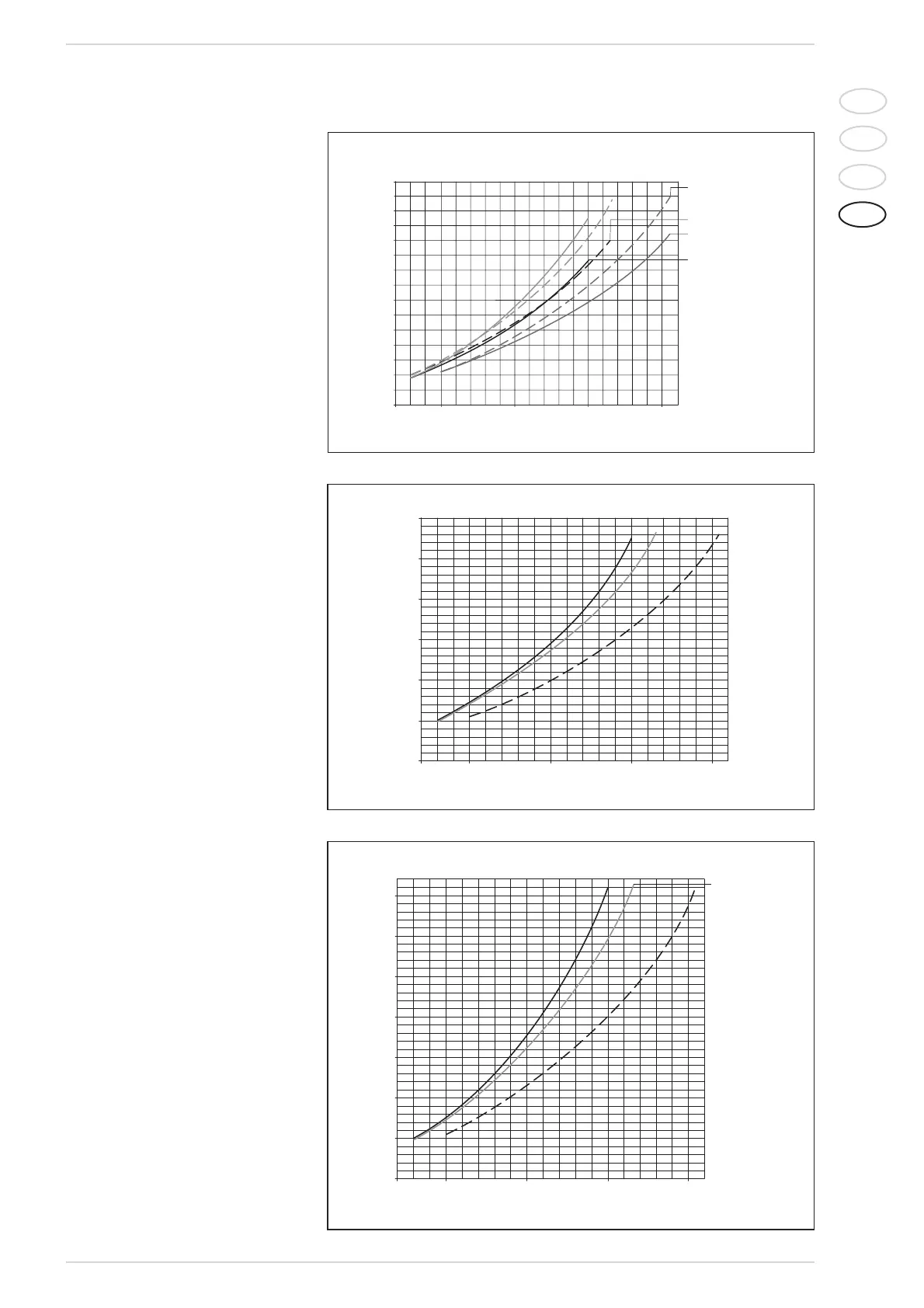

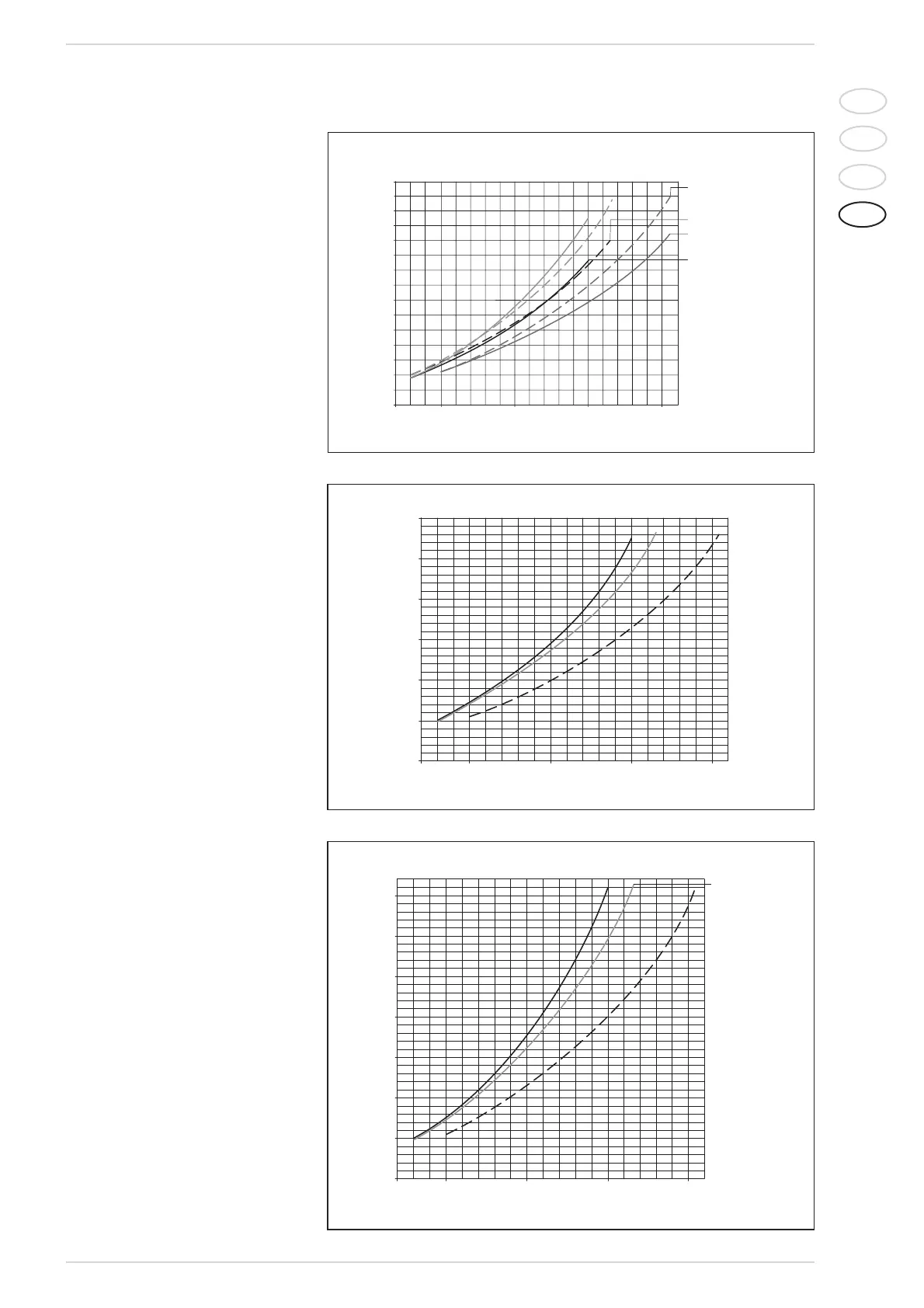

To facilitate the operations of adjusting heat

output, see the pressure/heat output dia-

grams for natural gas (methane) and buta-

ne or propane gas (figg. 26/a - 26/b -

26/c).

4.2.1 Measuring gas pressure at nozzles

To measure pressure at the nozzle, con-

nect a manometer to the intake down-

stream of the gas valve.

In “BF” models, connect the manometer as

shown in figure 27. This connection must

also be used when checking maximum and

minimum gas pressure; refer to the direc-

tions provided under point 4.4.1 if you need

to correct the settings.

4.3 GAS VALVE

The boilers are equipped standard with the

SIT 845 SIMGA/HONEYWELL VK 4105M

gas valve (fig. 28).

The gas valve is set at two pressure values:

maximum and minimum.

According to the type of gas burnt, these

correspond to the values given in Table 4.

The gas pressures at the maximum and

minimum values, are factory set. Conse-

quently they must not be altered.

Only when you switch the appliance from

one type of gas supply (methane) to

another (butane or propane), it is permit-

ted to alter the operating pressure.

4.4 GAS CONVERSION

This operation must be performed by

authorised personnel using original Sime

components.

To convert from natural gas to LPG or vice

versa, perform the following operations (fig.

89

IT

ES

PT

GB

4 USE AND MAINTENANCE

Loading...

Loading...