32):

– Close the gas cock.

– Disassemble the burner manifold (1).

– Replace the main nozzles (5) supplied in

a kit, inserting the copper washer (4).

Use a ø 7 spanner to perform this ope-

ration.

–

Remove the “METANO/GPL” connector

link on the card and set it in the posi-

tion corresponding to the gas to be

used (4 fig. 22).

– To set the values of maximum and mini-

mum gas pressure, follow the instruc-

tions given in section 4.4.1.

– After have ultimated the conversion of

the boiler, please stick onto the casing

panel the plate showing the relevant fee-

ding gas which is included into the kit.

NOTE: When reassembling components

which you have removed, replace gas

seals; test all gas connections after

assembly using soapy water or a product

made specifically for the purpose, being

sure not to use open flame.

4.4.1

Adjusting valve pressure

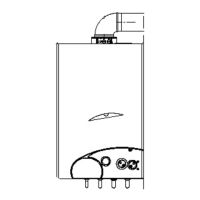

Set maximum and minimum pressure on

SIT 845 SIGMA or HONEYWELL VK

4105M valves as follows (fig. 29):

– Connect the column or a manometer to

the intake downstream of the gas valve.

In “BF” models, disconnect the valve

VENT pressure test point tube (5 fig. 28).

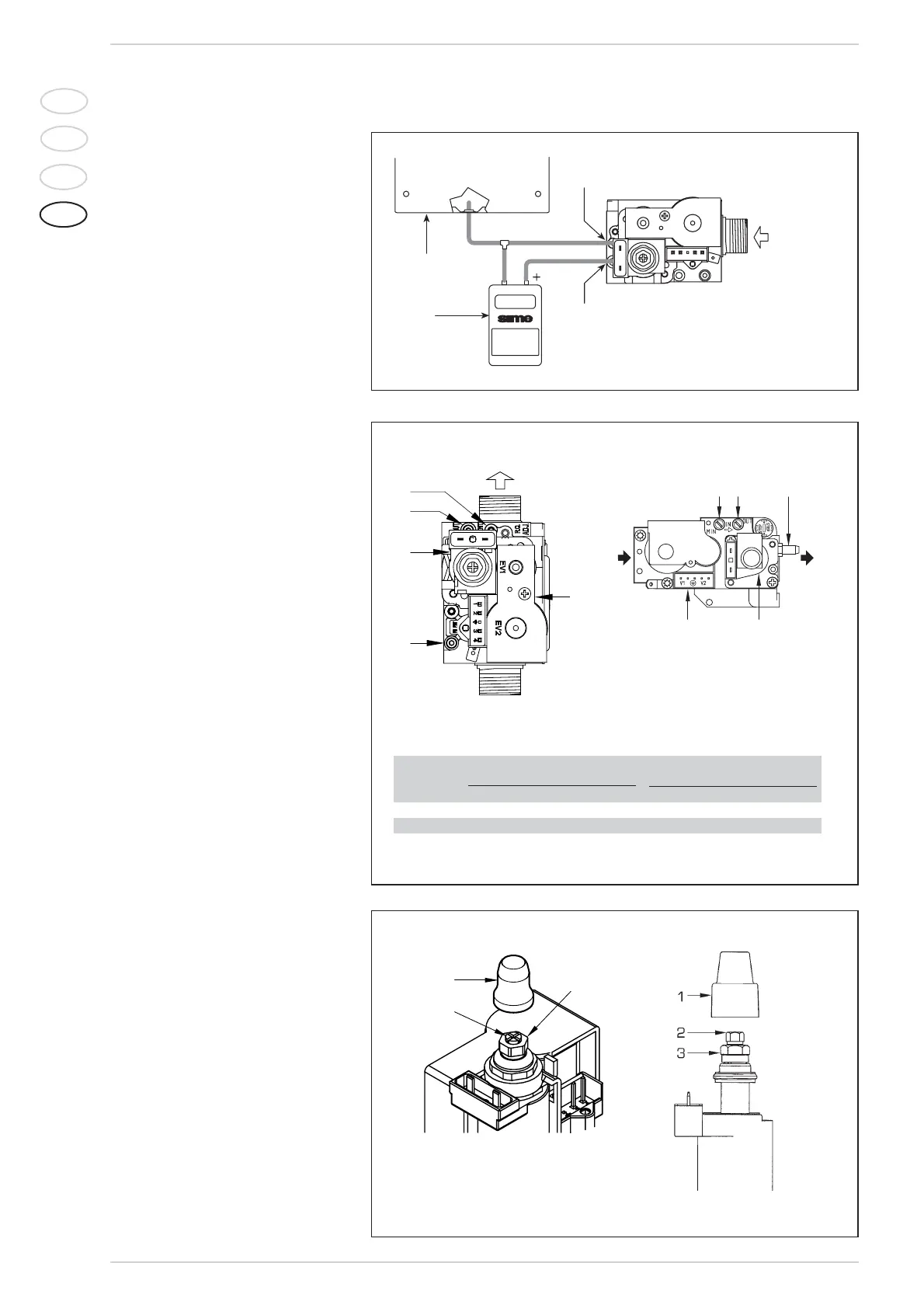

– Remove the cap (1) from the modulator.

– Place the hot tap water potentiometer

knob at the maximum position.

– Turn on the boiler using the four-way

switch and turn on a hot water tap all

the way.

– Remember that rotating clockwise will

increase pressure while rotating anti-

clockwise will diminish it.

– Adjust maximum pressure using the nut

(3) with a wrench (10 for 845 SIGMA, 9

for VK4105) to the maximum pressure

value indicated in Table 4.

– Do not adjust minimum pressure until

you have adjusted maximum pressure.

– Turn off the supply power to the modula-

tor, and keep the hot water tap turned

on.

– Lock the nut (3) in place, turn the screw

(2) for 845 SIGMA or the nut (2) using a

7 wrench for VK4105 to the minimum

pressure indicated in Table 4.

– Turn off the boiler and turn it back on

again several times, keeping the hot

water tap turned on at all times and

checking that the maximum and mini-

mum pressure values correspond to the

established values; correct the settings if

necessary.

– Adjust, checking that you have restored

the power to the modulator.

– Put the pipe back on the valve VENT

pressure test point.

– Remove the manometer, remembering

to tighten the screw for closing the pres-

90

IT

ES

PT

GB

Fig. 29

KEY

1 Plastic tap

2 Minimum pressure adjusting nut

3 Maximum pressure adjusting nut

SIT 845 SIGMA HONEYWELL VK 4105M

TABELLA 4

Burner max. Modulator Burner min. Modulator

Type of gas pressure mbar current pressure mbar current

25/60 OF 25/60 BF 30/60 BF mA 25/60 OF 25/60 BF 30/60 BF mA

Methane (G20) 9,7 11,0 11,3 130 1,8 2,0 2,2 0

Butane (G30) 27,5 28,2 28,0 165 5,0 4,9 5,5 0

Propane (G31) 35,5 36,2 36,0 165 5,0 4,9 5,5 0

Fig. 28

Loading...

Loading...