8

APPLIANCE PACKAGE:

- boiler (assembled);

- installation and servicing instructions;

- users instructions;

- wall mounting bracket;

- fixing screws with wall plugs.

3.1 FIXING THE WALL MOUNTING BRACKET

Before installing the appliance ensure that the chosen loca-

tion is suitable (section 2.2) and that the requirements for

flue position, (section 2.3), and minimum clearances, (

Table 2

)

are satisfied.

These minimum clearances are essential to provide access

for servicing, and are included on the wall mounting tem-

plates.

– Open the paper wall mounting templates. If a rear flue is

to be used, discard the side templates and secure the

rear template in the desired position. For a side flue appli-

cation, secure both the rear and appropriate side tem-

plate in position.

– Mark the position of the two wall mounting bracket fixing

holes and the flue/air duct hole on the appropriate wall(s).

– Remove the template(s) and drill the two fixing holes using

a 10 mm masonry drill. Fit the plastic plugs provided.

– Cut the hole in the wall for the flue/air duct. The diame-

ter should not be less than 100 mm (4 in) and must be

horizontal. Refer to fig. 12-14.

– Accurately measure the wall thickness, and note this

dimension for later use.

– Secure the wall mounting bracket in position using the

screws provided. Ensure that it is the correct way up, as

indicated in fig. 6.

3.2 HANGING THE BOILER

– Lift the appliance into position. The upper cross member

locates onto the wall mounting bracket.

– Screw in the wall mounting bracket adjusting screws until

the appliance is secure and vertical.

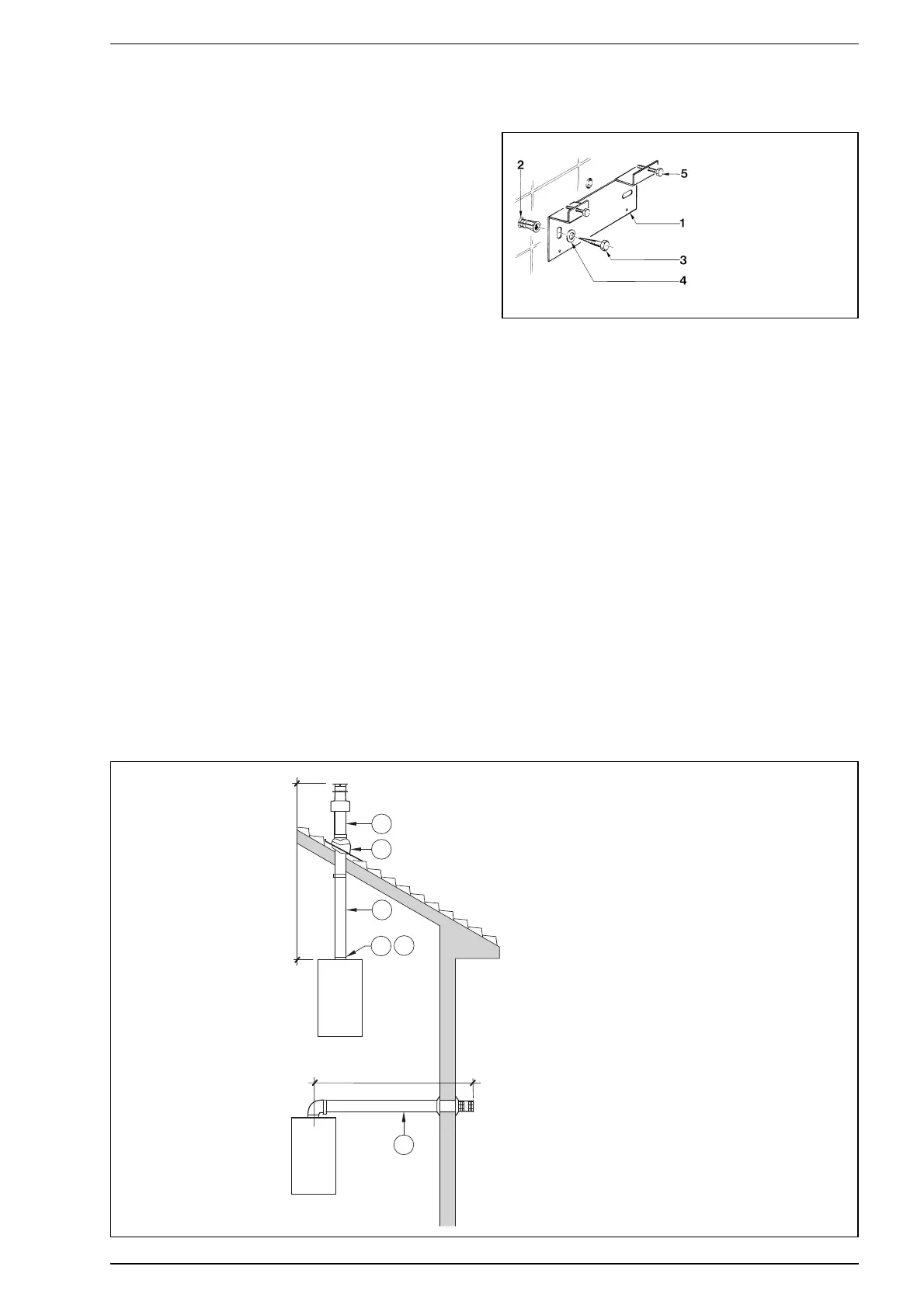

3.3 FLUE DUCTS MODEL “34I BF”

The air inlet-smoke outlet assembly ø 60/100 is supplied in a

kit code 8084811 complete with mounting instructions.

With the curve supplied in the kit the maximum horizontal

length of the flue must not exceed 3 metres.

When the extension code 8086908 is used, the end of

the flue must always have a horizontal outlet.

The diagrams in fig. 7 illustrate a number of examples of dif-

ferent coaxial outlets.

3 INSTALLING THE BOILER

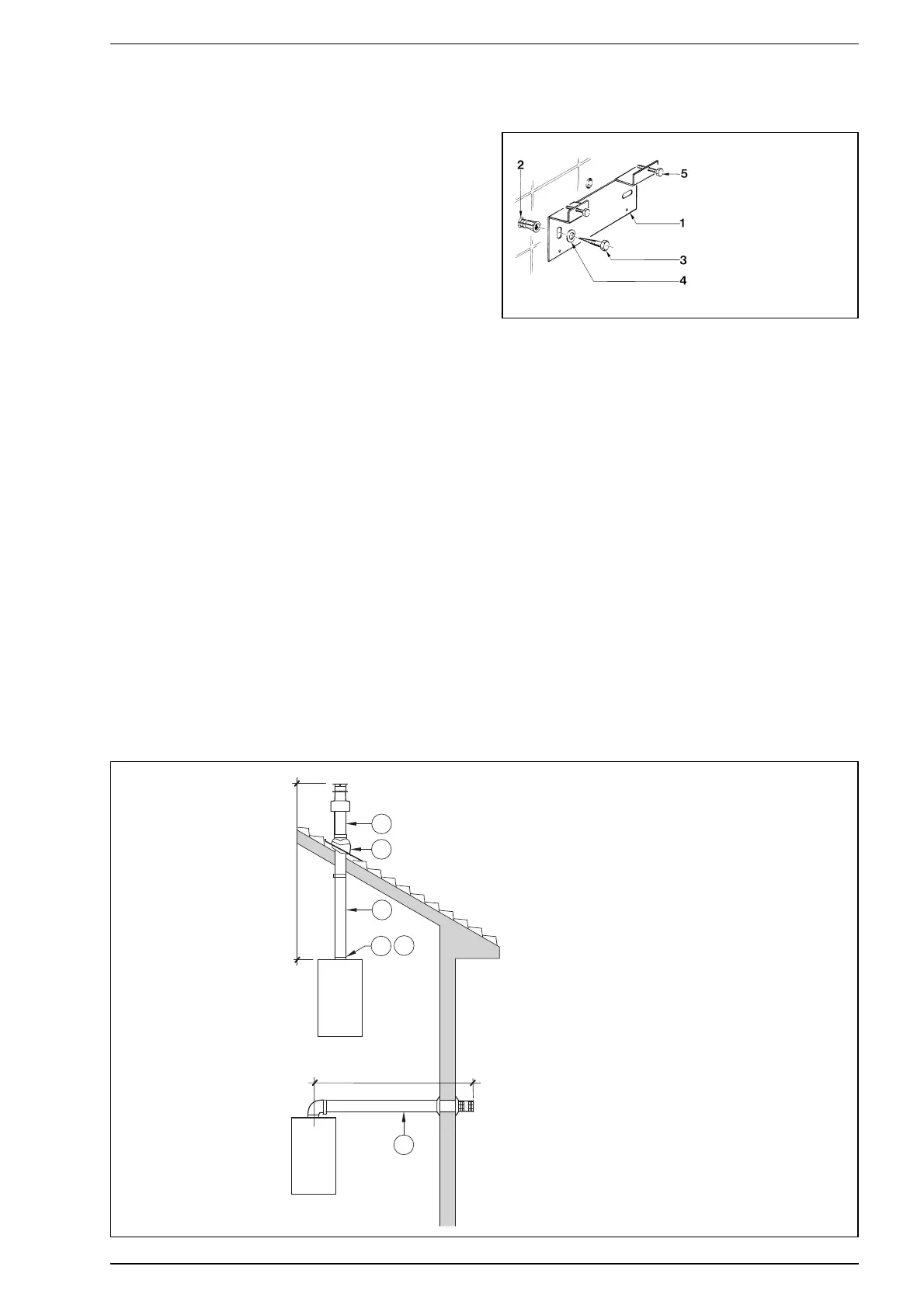

Fig. 6

KEY

1 Wall mounting bracket

2 Plastic wall plug (2 Off)

3 Woodscrew (2 Off)

4 Washer (2 Off)

5 Adjustment screw (2 Off)

KEY

1 Coaxial flue kit code 8084811

2 a Extension L. 1000 code 8096100

2 b Extension L. 500 code 8096101

3 Vertical extension L. 200 code 8086908

4 Additional 90° curve code 8095800

6 Articulated tile code 8091300

7 Roof outlet terminal L. 1284 code 8091200

8 Vertical condensation collector L. 200 code 8092803

Fig. 7

IMPORTANT:

– Each additional 90° curve installed reduces

the available length by 0.90 metres.

– Each additional 45° curve installed reduces

the available length by 0.45 metres.

– It is advisable to assemble the condensation

collector (8) on vertical segments exceeding

2.5 metres in length and to limit maximum

length to 4 metres.

max 3 m

min. 1,3 m - max. 3 m

Loading...

Loading...