3.1 ELECTRONIC IGNITION

The “IONO” boilers are equipped with

electronic ignition without pilot flame;

they are therefore equipped with an

electric control and protection device.

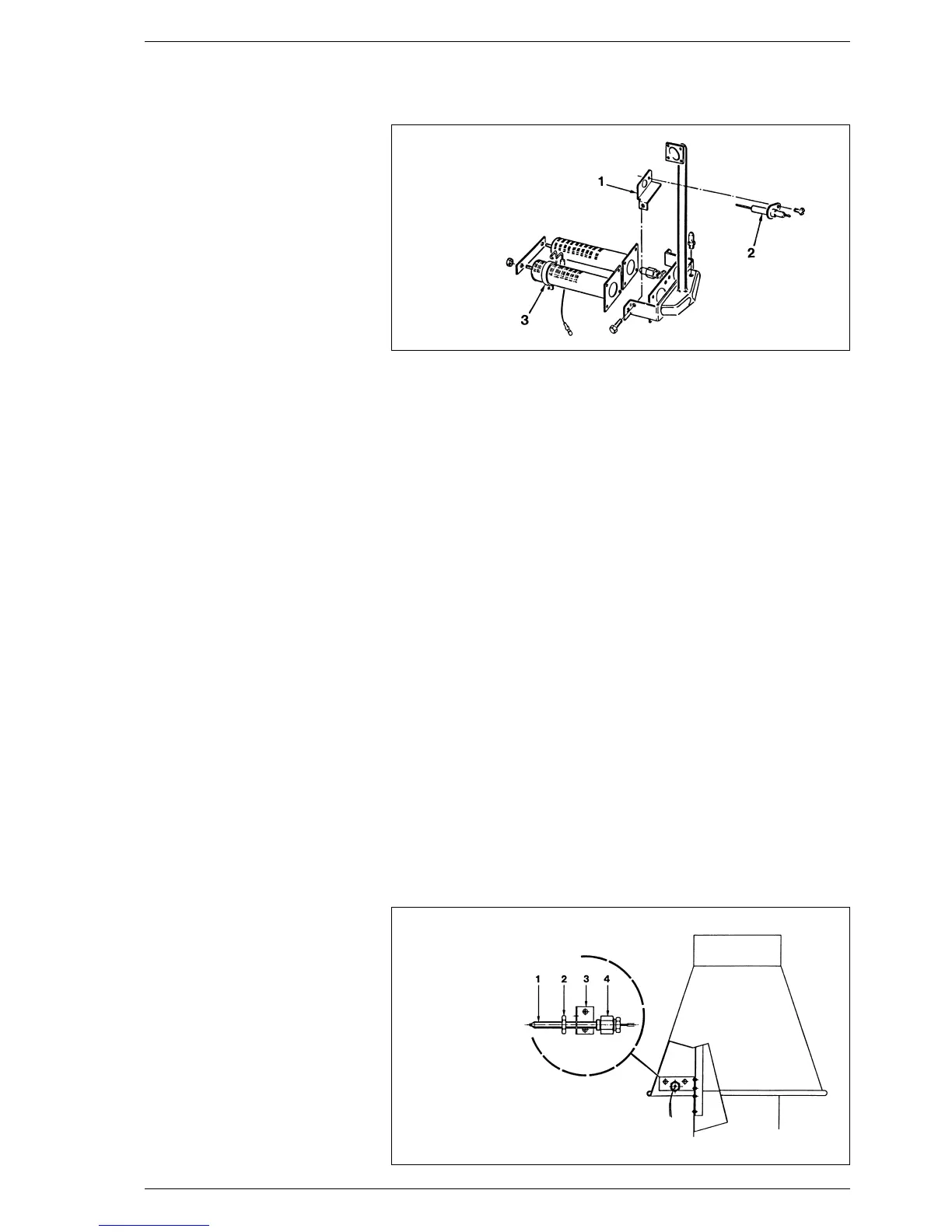

An electronic programmer, model

Brahma FM 11, controls the ignition

and the ionisation by means of two

electrodes as shown in fig. 5.

Maximum safety is garanteed because

in case of accidental extinction of the

burner the gas flow is stopped within 1

second. A reference mark made on

the burner ensures the proper applica-

tion of the ignition electrode.

3.1.1 Working cycle

Before lighting the boiler check with a

voltmeter that the electric connection

to the terminal board has been pro-

perly made observing the phase and

neutral positions of the wiring diagram.

Press the main switch on the control

board; the lamp will light if there is

power. At this stage the boiler will start

to work sending, via the FM 11 pro-

grammer, a discharge current to the

electrode and, at the same time, ope-

ning the gas valve. Normally the burner

takes 1 or 2 seconds to light.

It may however fail to light, in which

case the boiler lock-out lamp will be

activated. The main causes maybe:

– No gas supply

The equipment performs regularly

sending voltage to the ignition elec-

trode that continues to spark for max.

10 seconds, without detecting the

burner starting, then it shuts down.

It may occur at the first starting or

when the boiler has not been used

for a long period of time and there is

air in the pipes. It may occur if the

gas cock is closed or if the winding of

one of the valve coils is interrupted,

thus preventing it from opening.

– There is no spark

In the boiler you will only notice the

gas flow to the burner, after 10

seconds it shuts down.

It may be due to the fact that the elec-

trode cable is disconnected or is not

properly fixed to the terminal 10; or

the equipment transformer is burnt.

– No ionisation

From the time of the starting you

can observe the electrode continuos

sparking even if the burner is on.

After 10 seconds the sparking stops

and so does the burner, while the

lock-out lamp appears to be on.

It occurs if the phase and neutral posi-

tion on the terminal board has not

been observed. The detection electro-

de cable is disconnected or the elec-

trode itself is earthed; the electrode is

very worn-out and needs replacing.

The sudden lack of voltage causes the

immediate shutdown of the burner and

when the voltage is restored the boiler

will automatically restart.

3.1.2 Ionization circuit

The ionization circuit shall be checked

with a normal microammeter, or even

better, with a digital microammeter

with a 0÷50 µA range.

The microammeter terminals shall be

electrically connected in series to the

ionisation electrode cable.

Under standard conditions the value

varies from 4÷6 µA. The minimum ioni-

zation current value, at which the

equipment may shut down, is approxi-

mately 1 µA. In this case it will be

necessary to check that there is a

good electric contact and to check the

wear of the electrode tip and of its

ceramic protection.

3.2 SMOKE SAFETY DEVICE

The smoke stat provides a protection

against the discharge of flue gas into

the atmophere (3 fig. 2).This control

device stops the gas valve if the flue

gas is descharged into the boiler room

is continuous way and in such quanti-

ties as to become dangerous.

To start the boiler again, switch off the

power, then remove the smoke stat

cover and reset the button below.

If the thermostat continues to trip off,

it will be necessary to check the flue

thoroughly, making all the necessary

changes to ensure it works properly.

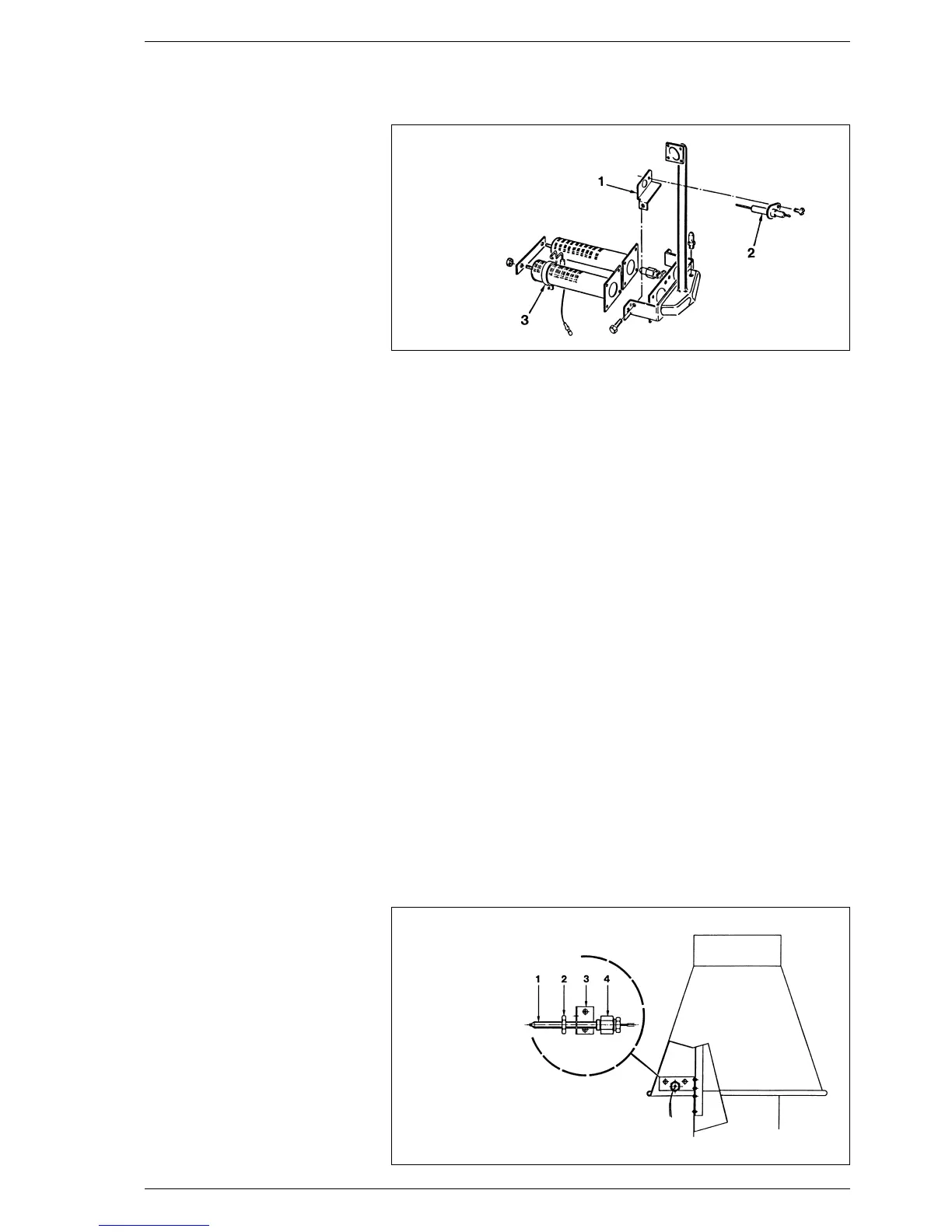

On the “RX 37÷55” models, the

smoke stat capillary on the back of the

boiler shall be put into the 12.5 ø hole

of the droughtdiverter support bracket

and fixed to it with the fitting and the

M12 lock nut already mounted on the

capillary (fig. 6).

50

3 CHARACTERISTICS

KEY

1 Ionisation electrode support

2 Ionisation electrode

3 Ignition electrode

Fig. 5

KEY

1 Smoke stat capillary

2 M12 lock out

3 Capillary support bracket

4 M12 fitting

Fig. 6

Loading...

Loading...