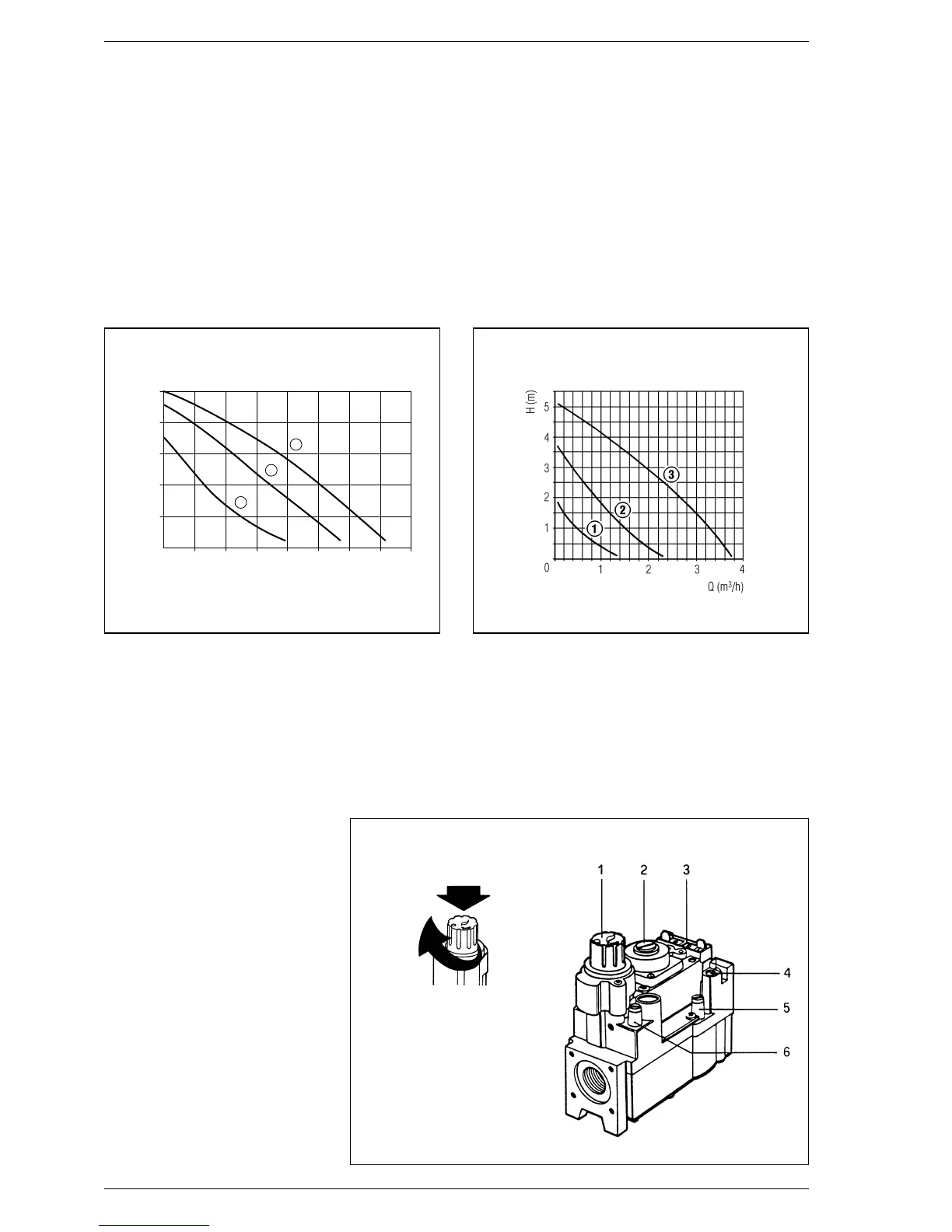

4.1 ADJUSTING GAS VALVE

“19÷55” VERSIONS

Standard “RX 19÷55 CE” and “RX 19-

26 PVA CE” boilers feature a

HONEYWELL V4600C gas valve (fig.

8). When the boiler is ignited for the

first time, it is always better to purge

the pipe by using the inlet pressure tap

(6) on the gas valve.

The pilot burner gas flow rate shall be

adjusted on the screw (4): to decrease

the pilot flame rotate the screw

clockwise; to increase the pilot flame

rotate the screw anticlockwise.

To adjust the main burner gas pressu-

re remove the plug on the pressure

regulator (2). The regulation is made

by rotating the screw under the plastic

plug with a screwdriver: rotate the

nylon screw anticlockwise to reduce

the pressure, clockwise to increase it.

51

3.3 SAFETY STAT

In case the boiler temperature

exceeds 95°C the safety stat (6-14 fig.

2), will extinguish the pilot burner thus

shutting off the gas flow to the pilot

and main burner.

“RX 19-26” models are equipped with

safety stat with automatic resetting,

and “RX 37÷55” with manual reset-

ting. Should the stat with manual reset-

ting trip off, it will be necessary to

unscrew the cover and reset the but-

ton below for the pilot burner to

restart.

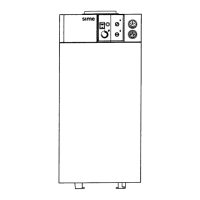

3.4 CIRCULATING PUMP

PERFORMANCE CURVES

The “RX PVA” boilers can be equipped

with either EURAMO NYL 40/25 or

GRUNDFOS UPS 25/50 circulating

pumps.

Both have a built-in speed selector for

adjusting head and capacity.

Head and capacity performance cur-

ves of the standard circulating pump,

at different speeds, are given in fig. 7.

NOTE: Before starting the boiler

check that the circulating pump is

not locked.

Loading...

Loading...