Preventative visual inspection of the shipping crate, Remote Pump

Unit, and accessories must be performed before installation.

Physical or electrical problems due to handling and vibration may

occur during shipment.

1. If the packing crate shows signs of damage inspect the

SPS cabinet for damage. Check the entire outside of the

cabinet for damage which could cause internal

mechanical or electrical problems.

2. Check main disconnect switch, door and hinge

operation.

3. Check pump/motor hardware for tightness. Rotate

motor shaft by hand and check for smooth operation.

Check pump/motor coupler for proper alignment and

spacing. The coupler should have approximately 1/8"

clearance between coupler halves. If this clearance is

reduced or the pump and motor are not properly aligned

excessive noise and pump/motor wear will occur.

4. Check all electrical terminals and connections for

tightness.

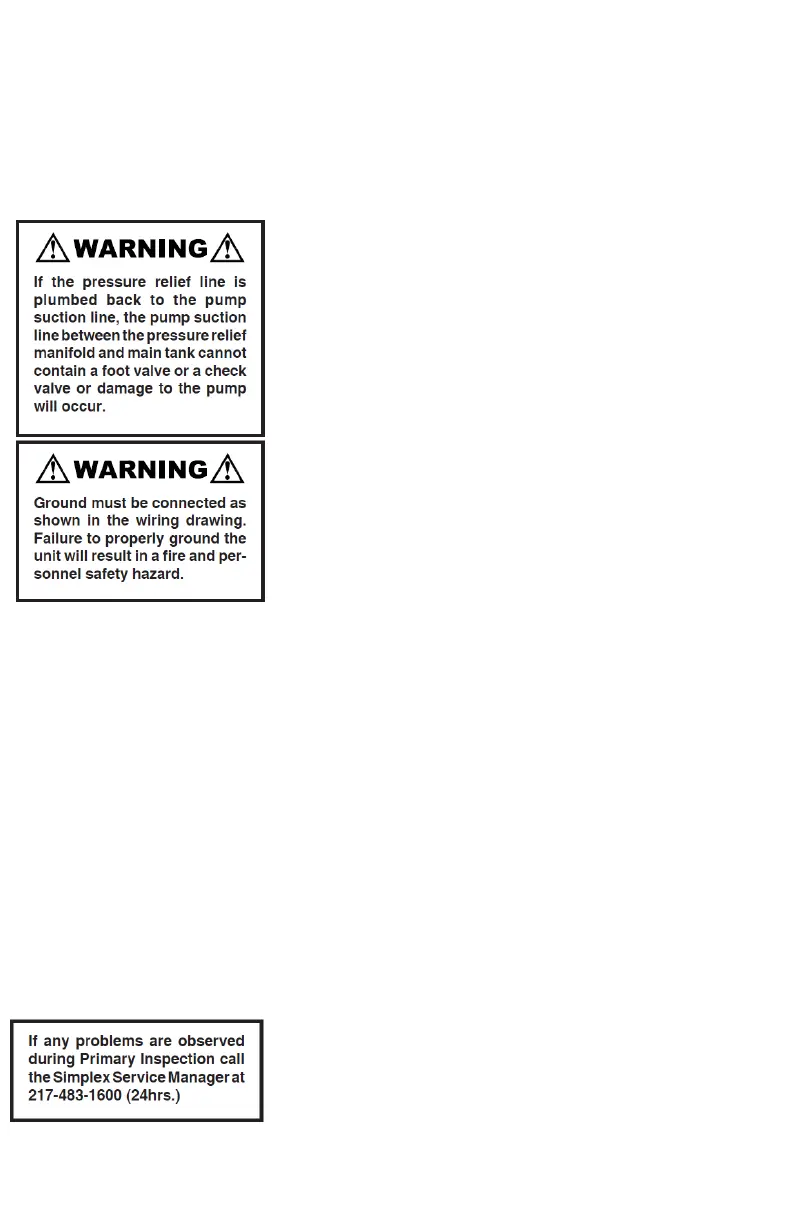

1.Properly mount and attach all components as shown in

the dimensional drawings using the mounting feet/holes

and plumbing provided. The pressure relief manifold

should be plumbed back to the main fuel tank.

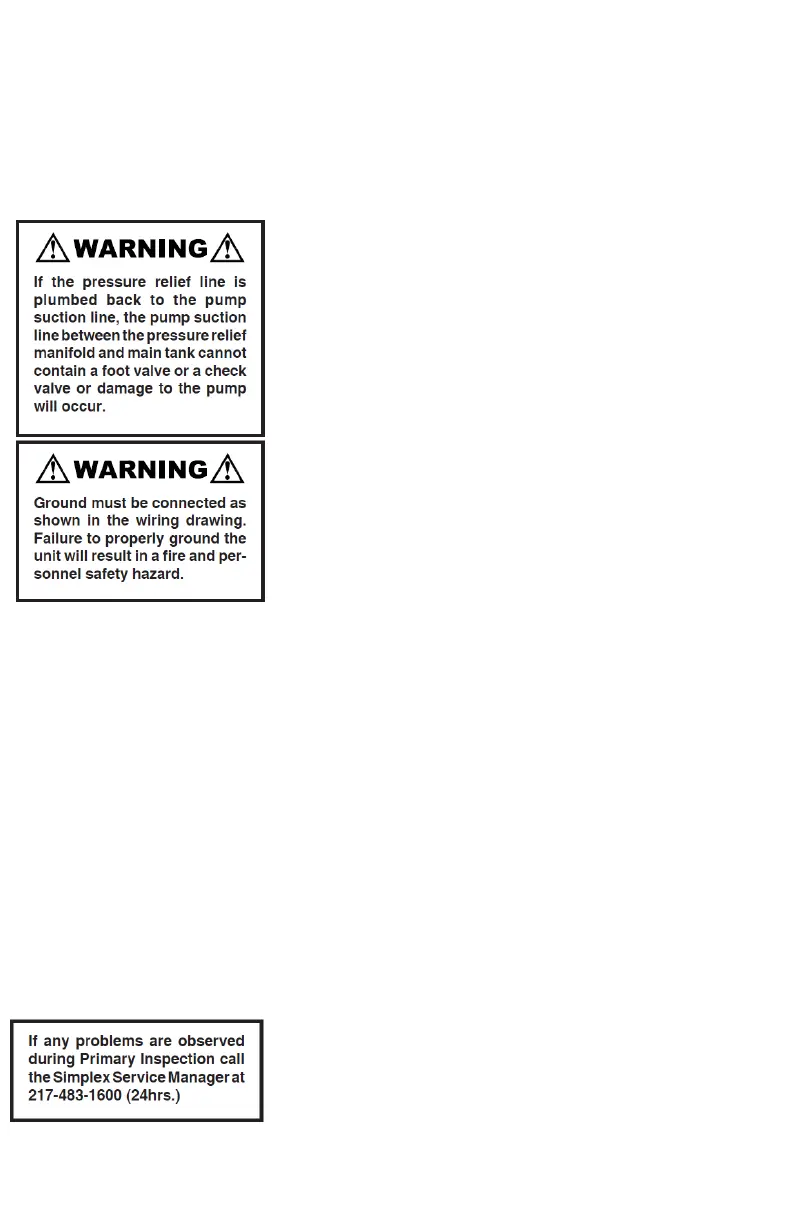

2.Connect all components to earth ground at ground

studs provided as shown on the electrical drawings.

Unit must be grounded for operator safety.

3. If equipped, install level and alarm indication

accessories as shown on dimensional drawing and

connect them to the Pump Unit as shown on the

electrical drawings.

4. If equipped, connect dry alarm contacts for customer

use per specifications on the electrical drawings.

5. Connect pump motor/control power to the Remote

Pump Unit per specifications on the electrical drawings.

Loading...

Loading...