In connection with the machine, please use the coupling, as well as the

axis of the servo motor and mechanical axis to keep in a straight line, the

circumference radial pulsation of the shaft coupling should not be

greater than 0.03mm. If the centering is not sufficient, it will produce

vibration, it can damage the bearings and encoders etc.

The servo motor can be installed in horizontal direction or vertical

direction, do not install slant, otherwise it may cause motor bearing

wear.

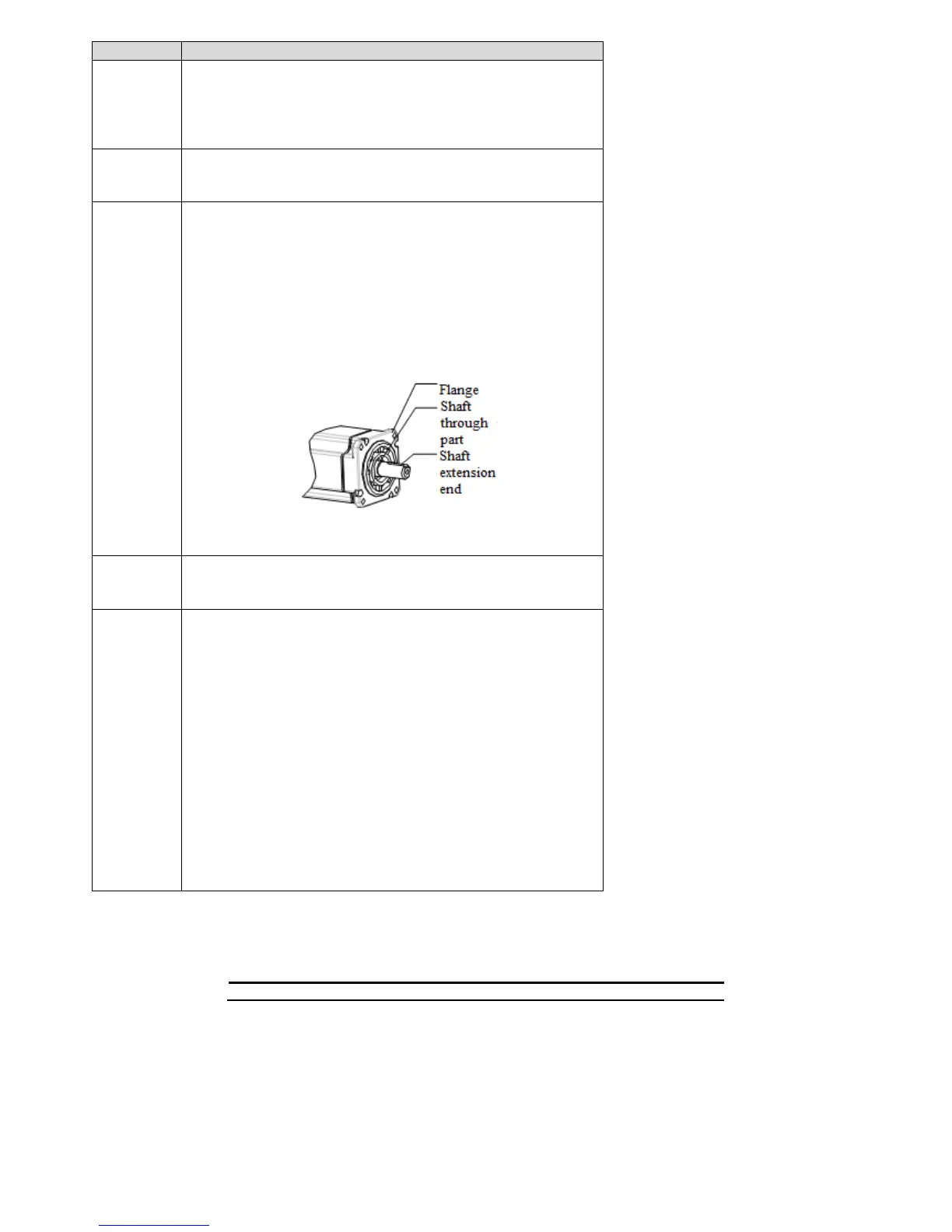

When using at the place of water droplets drop , please confirm the servo

motor on the basis of the protection level (except the shaft through part).

When using for the site of oil droplets will drop to the shaft through part,

please specify the use of oil seal with the servo motor.

The servo motor operating conditions with oil seal:

Please ensure the oil level is lower than the oil seal lip when

using.

Please use when oil seal can keep oil splash in a good condition.

In the servo motor vertical installation, please pay attention not to use oil

seal.

Shaft through part: Refers to the gap of motor shaft from the end surface of the

protruding part

Stress condition

of cable

Don't make cable excessive bending or tension is applied to it, especially the

core wire of the encoder signal line is 0.12 mm or0.22 mm, very fine, so in

wiring and using, please don't make the stretching tight.

For connector parts, please note the following:

The connector, please confirm there is no garbage or metal debris and

other foreign bodies in connector.

The connector connects to the servo motor please first from one side of

the servo motor circuit cable and cable main grounding wire must

reliable connection. If first connected one side of the encoder cable, the

encoder may be fault caused by the potential difference between the PE.

The connection, please confirm the correct pin arrangement.

The connector is made of resin. Do not apply impact to prevent damage

to the connector.

When cable maintain connection to handle, please hold the servo motor

main body. If only seize the cable handling, may be damaged or broken

cable or connector.

If you need to bend the cable, you should pay full attention to the

wiring , do not make the connector part of the pressure or tension, or

may cause the connector damage or poor contact.

2.6 Circuit breakers and fuse recommendations

If there is a drive to install the leakage circuit breaker to be used as the leakage fault protection, to prevent leakage circuit breakers

malfunction, please select the model about the sense of current in the 200mA above and the action time of 0.1 seconds above.

Fuse, please use the fast fuse model, its rated current should be based on the drive capacity of about 1.5 times.

Strongly recommended: The fuse and circuit breakers recognized by UL/CSA .

2.7 Brake resistance selection

When the motor's output torque and speed in the direction of the opposite, the energy will be transmitted back to the drive from the load.

This energy will be poured into the bus bar so that the voltage value of the bus inside the drive is increased, and the magnitude of the recharge

energy depends on the inertia of the motor and the load. If the system inertia small, may through drive internal capacitors to absorb recharge

energy, but if the system inertia is large, more than the energy that capacity absorb, voltage value may rise too high, causing the drive stop or

even damage, so when the voltage rises to a certain value, recharge energy must by a braking resistor to consume.

The following table 2-1 lists commonly used SER series servo motor rotor inertia and EA100 drive internal capacitive absorption ability, and

retrogradation energy calculation formula.

Loading...

Loading...