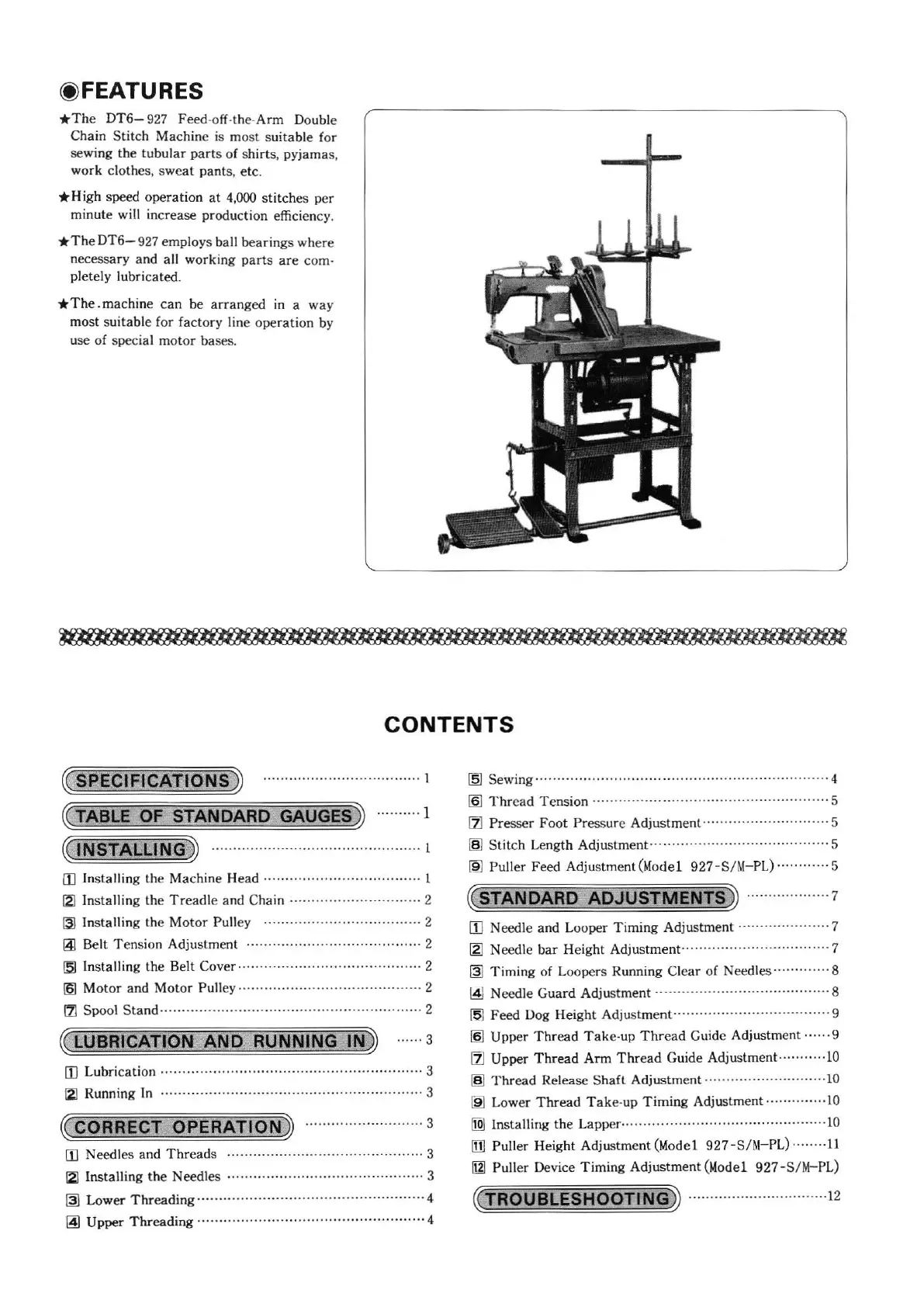

(f) FEATURES

*The

DT6-927

F

eed

-off-th

e-Arm

Double

Chain

S

tit

ch Machine is

most

suitable for

sewing

th

e

tu

bular

p

ar

ts of shirts, pyjamas,

work

clothes,

swe

at

pant

s, etc.

*High

speed

operat

ion

at

4,000

st

itches

per

minute

will incr

ease

production efficiency.

*TheDT6-

927 employs ball

bearings

where

necessary

and

all

working

p

arts

are

com-

pletely lubri

ca

ted.

*The.machine

can

be

arranged

in a

way

most

suitable

for

factory

line

operation

by

u

se

of

special

motor

bases.

CONTENTS

~

SPECIFICATIONS

~

............

............

..

..........

1

~

Sewing

........

...

.................

.....

................

.......

......

..... 4

~

TAB

LE

OF

STANDARD

GAUGES

»

..........

1

[§]

Thr

ead

Tension

...............

...

........

................

............

5

1Zl

Presser

Foot

Pressure Adjustment

..............

·

........

· .. · .. 5

~

J

N

STA

L

LING

~

............

..

........................

..

........

l

[I]

Ins

talling

the Machine

He

ad

....................................

l

121

Installing

th

e

Treadl

e and Chain ....

........

.

......

....

....

... 2

~

Stit

ch Le

ngth

Adju

st

ment

..

.......................................

5

~

Puller

Feed

Adju

stment(Mo

del

927-S

/

M-PL

) ............ 5

~

STANDARD

ADJUSTMENTS»

....

.........

......

7

(3]

In

sta

lling

the

Motor

Pulley

....................................

2

[I] Needle

and

Lo

oper

Timing

Adju

stment

...

........

.........

· 7

~

Belt

Tension

Adjustme

nt

........

...................

........

.... · 2

~

Needle

bar

Height Adjustment

....

............

.............

.....

7

[5)

Installing

th

e

Belt

Cover .... ·

..............

· .. · .. · .. ·

........

· .... 2

@]

Timing

of Loopers Running

Clear

of

Need

l

es

.........

.... 8

161

Motor

and

Motor

Pulley

..........................................

2

~

Needle

Guard

Adjustment

............

.......

...........

..........

8

111

Spool

Sta

nd

.... ·

....

..........................

·

........

··

....

..........

2

[5]

Feed

Dog

Height

Adj

ustment"

...............

....

........

..

.....

9

~

LUBRICAT

I

O

N

.

AND. RUNNING

IN

~

......

3

[I]

Lubrication

···

.....

· ..

.........

·

.................

· .. · ·

.................

3

121

Running In ....

.............

............

....................

....

......

· 3

[§]

Upper

Thread

Take

-up

Thread

Guide Adjustment

......

9

11J

Upper

Thread

Arm

Thr

ead

Guide Adjustment

...........

10

1§1

Th

r

ead

Release

Sha

ft

Adjustment

.......

.....................

10

~

Low

er

Thread

Tak

e-

up

Timing

Adjustment .....

.........

1Q

~

CORRECT

OP

E

RATION

~

...........................

3

[I]

Needl

es

and

Thread

s

.....

..............

..........................

3

(2]

In

st

alling

the

Need

l

es

...... ·

........

··

...

· · ·

...................

·· · 3

[I2J

In

sta

lling

th

e Lapper· .. ·

...

. ·

........................

.............

·

lO

[1]

Puller

Height

Ad

justme

nt (Model 92

7-

S/M

-PL)

........

11

~

Puller Devi

ce

Timing

Adjustment (

Mod

el 927 -S/ M- PL)

@]

Lower

Threading··

·········

····

·

···········

·························

4

~

TROUBLESHOO

TI

NG

»

......

...........

..

..

...........

12

~

Upper

Threading

· · · · · .. · · · · · · · · · · · .. · · · .. · · · · · · · · .. · .. · · · · · · · · · .. · · · 4

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...