~3~

~LUBRICATION

AND

RUNNING

IN~

ill

lubrication

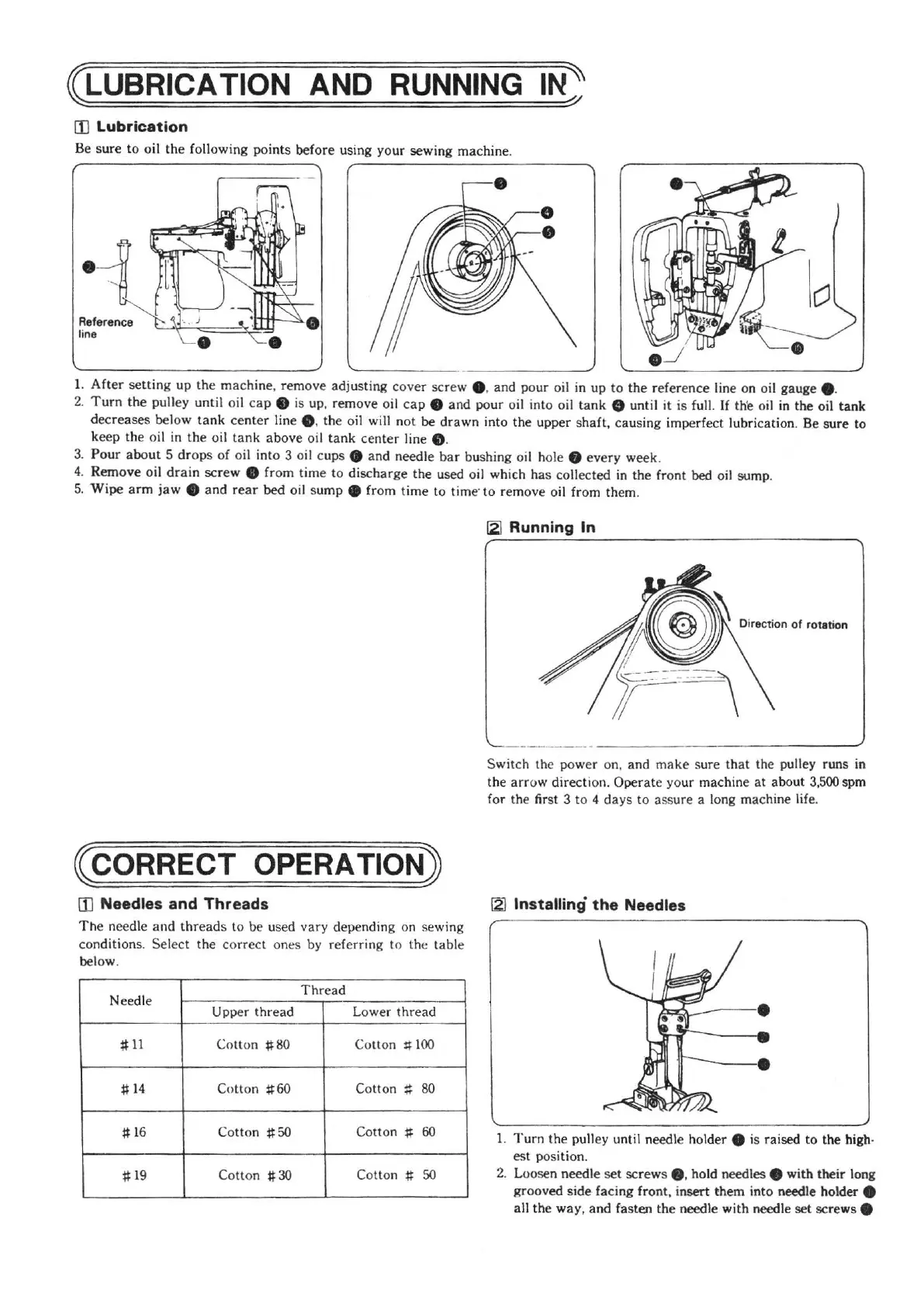

Be

sure

to

oil

the

following

points

before using

your

sewing machine.

1.

After

setting

up

the

machine

, remove adjusting

cover

screw

e.

and

pour

oil in

up

to

the

reference

line on oil gauge e.

2.

Turn

the

pulley until oil

ca

p e is

up

, remove oil

cap

e

and

pour

oil into oil

tank

0 until it is full.

If

th'e o

il

in

the

oil

tank

decreases

below

tank

center

line e. the oil will

not

be

drawn

into

the

upper

shaft,

causing imperfect lubrication. Be

sure

to

keep

the oil in

the

oil

tank

above

oil

tank

center

line e.

3.

Pour

about

5

drops

of

oil

into

3 oil

cups

e

and

needle

bar

bushing oil hole e

every

week

.

4.

Remove

oil

drain

screw

e from

time

to

discharge

the

used oil which

has

collected in

the

front bed oil

sump

.

5.

Wipe

arm

jaw

e

and

rear

bed

oil

sump

e from

time

to time· to remove oil from them.

~CORRECT

OPERATION)

!I]

Needles and Threads

The

n

eed

le

and

thread

s

to

be

used vary depending on sewing

conditions.

Select

the

correct

ones

by

referring

to

the

table

below.

Needle

Thread

Upper

thread

Lower

thread

~11

Cotton

~80

Cotton

#

100

~

14

Cotton

~60

Cotton

~

80

~

16 Cotton

~50

Cotton

~

60

~

19

Cotton

#

30

Cotton

~

50

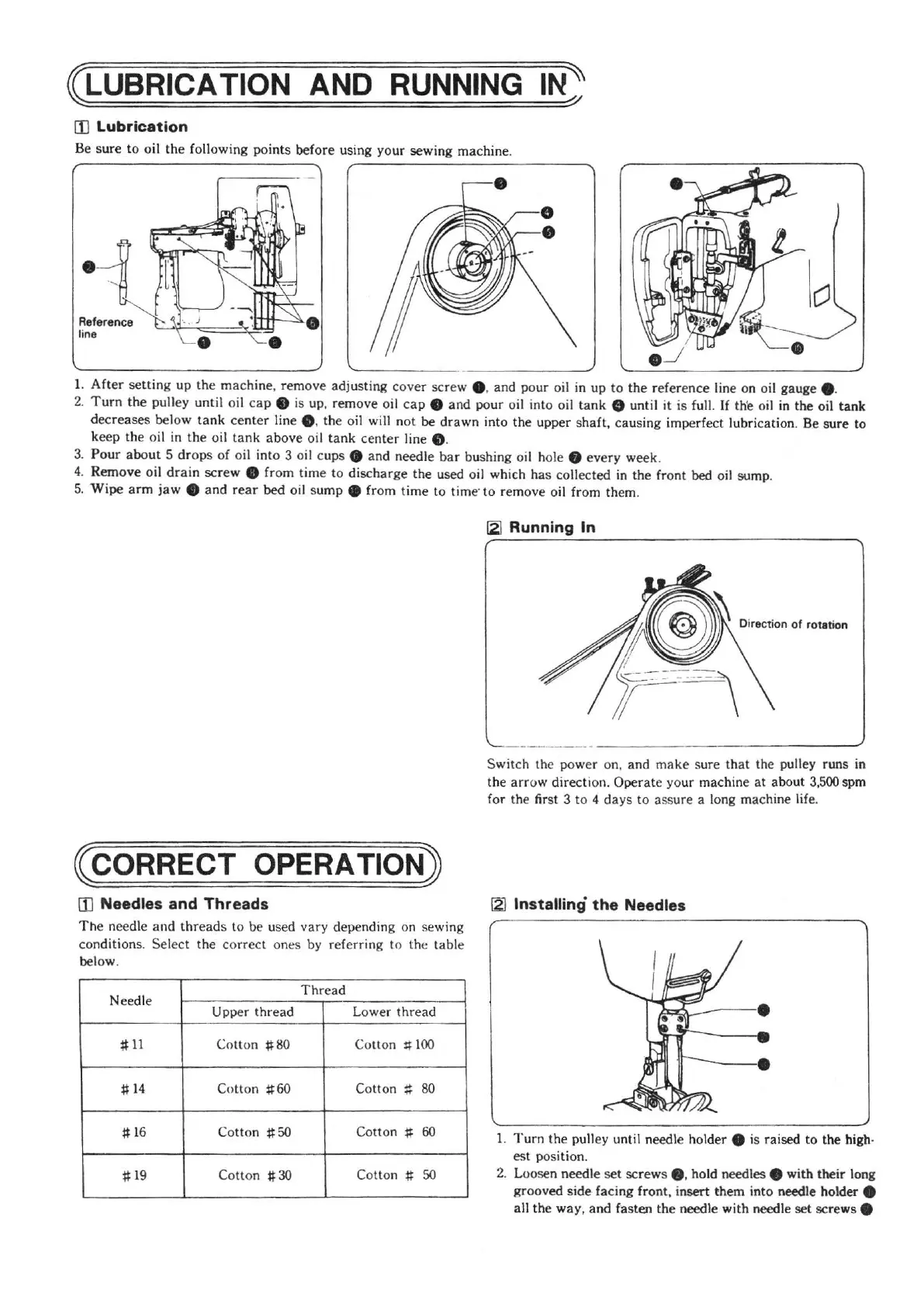

[21

Running

In

- -·-··

··--·-

---

---·

---

-

----'

Switch

the

power

on,

and

make

sure

that

the

pulley runs in

the

arrow

direction.

Operate

your machine

at

about 3,500 spm

for

the first 3 to 4

days

to

a

ss

ur

e a long machine life.

~

Installing

the

Needles

1.

Turn

the

pulley until needle holder e is raised

to

the

high·

es

t position.

2. Loosen needle

set

scre

ws

e.

hold needles e with

their

long

grooved side facing front, insert them i

nto

needle holder e

all

the

way,

and

fasten

the

needle

with

needle

set

screws

e

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...