7

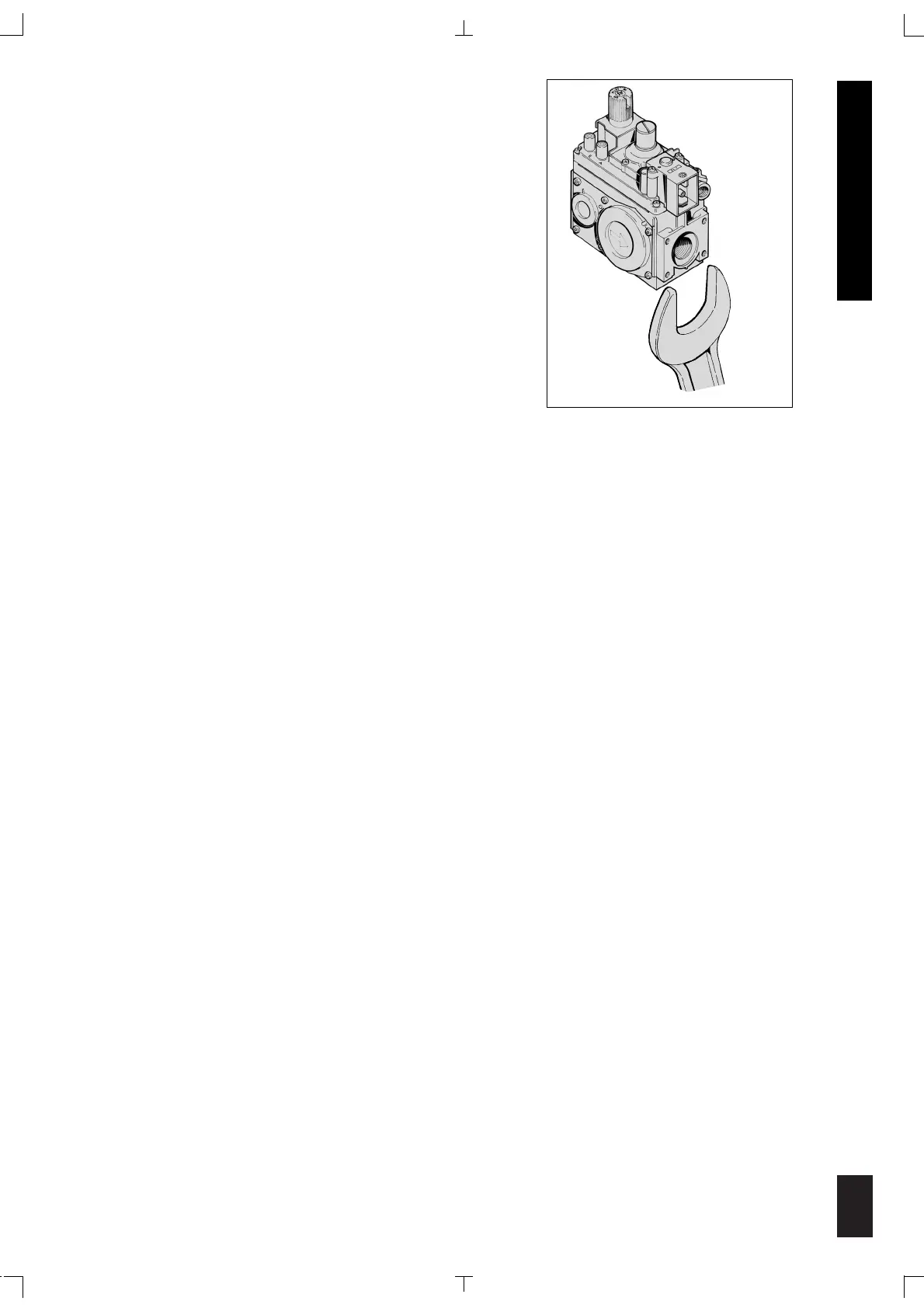

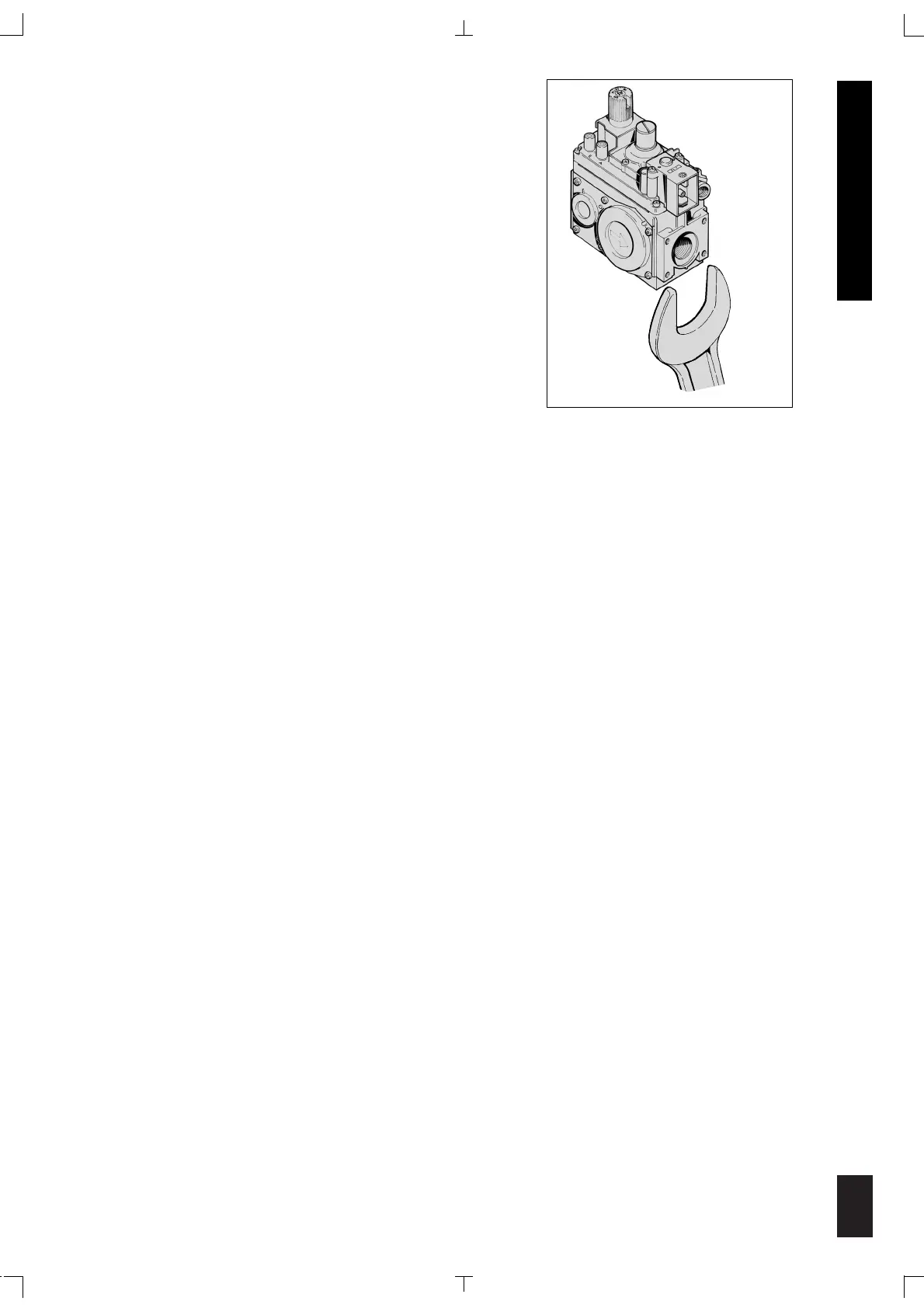

Fig. A

INSTALLING THE VALVE

1. Mount the valve in the desired position.

2. Mount the valve so the flow of gas is consistent with the

gas flow arrows on the valve.

3. Apply a moderate amount of quality pipe compound

(DO NOT USE TEFLON TAPE) to the pipe only, leaving

two end threads bare. On LP installations, use

compound that resists exposure to LP gas.

4. Remove seals over inlet and outlet if necessary

5. Connect pipe to valve inlet and outlet. Place wrench on

valve as shown in (fig A).

6. Thread pipe into the valve until a gas tight seal is

achieved. Typically, for NPT thread, penetration is usually no more than the diameter of the

pipe or 2 and 1/4 turns of thread. Valve distortion or mechanical failure can result if the pipe is

inserted too deeply.

7. Connect pilot tubing to valve with appropriately sized fittings.

8. Confirm gas tight seals with gas leak test.

WIRING

Follow the wiring instructions furnished by the appliance manufacturer, if available, or use the

following general instructions. Appliance manufacturers instructions always supercede these

instructions.

All wiring must comply with applicable electrical codes and ordinances.

Disconnect the appliance power source before making any electrical connections to prevent the

possibility of electrical shock or damage to equipment.

1. Check the millivolt rating on the gas valve and make sure it matches the available supply. Install

thermostat and other accessories as required.

2. For the Millivolt Plus, connect thermocouple to convenient upper or lower connection port. Hand

tighten, and then rotate 1/4 turn with wrench.

3. Connect the Thermo-generator leads to TPTH and TP terminals on main operator coil.

4. This valve may only be used in self-generating systems. Use only components specifically

designed for use in a millivolt system.

ENGLISH

Loading...

Loading...