4.4 Operationofair-drivengreasepumpsLAGG18AE,LAGG50AE

andLAGG180AE

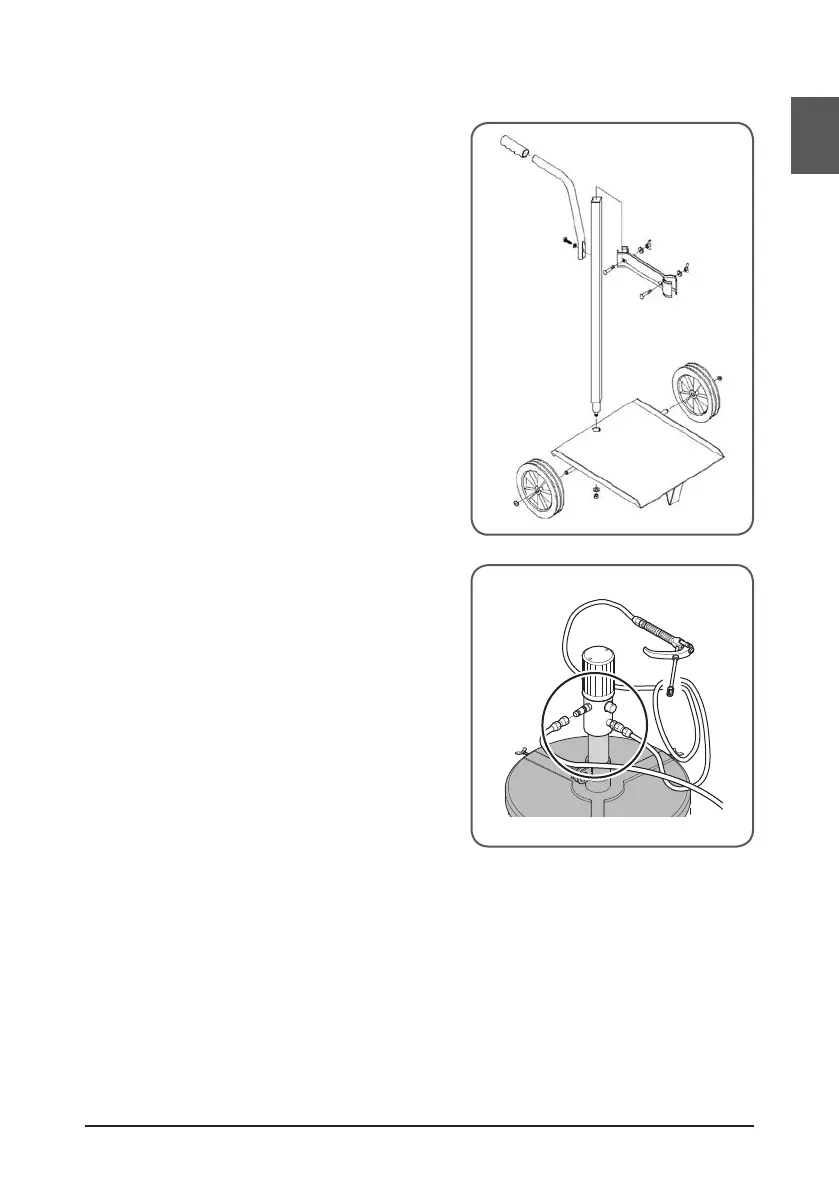

ForLAGG18AEonly

1. Assemblethetrolleyandputthegrease

drumonthebase.Thetrolleycanbe

usedfora50kgdrum.

2. Connectthetrolleybarmembers

aroundthesquaretrolleyrodandthe

pistonrod.

3. Attachthehandleandsecureitin

positionbymeansofthescrew.

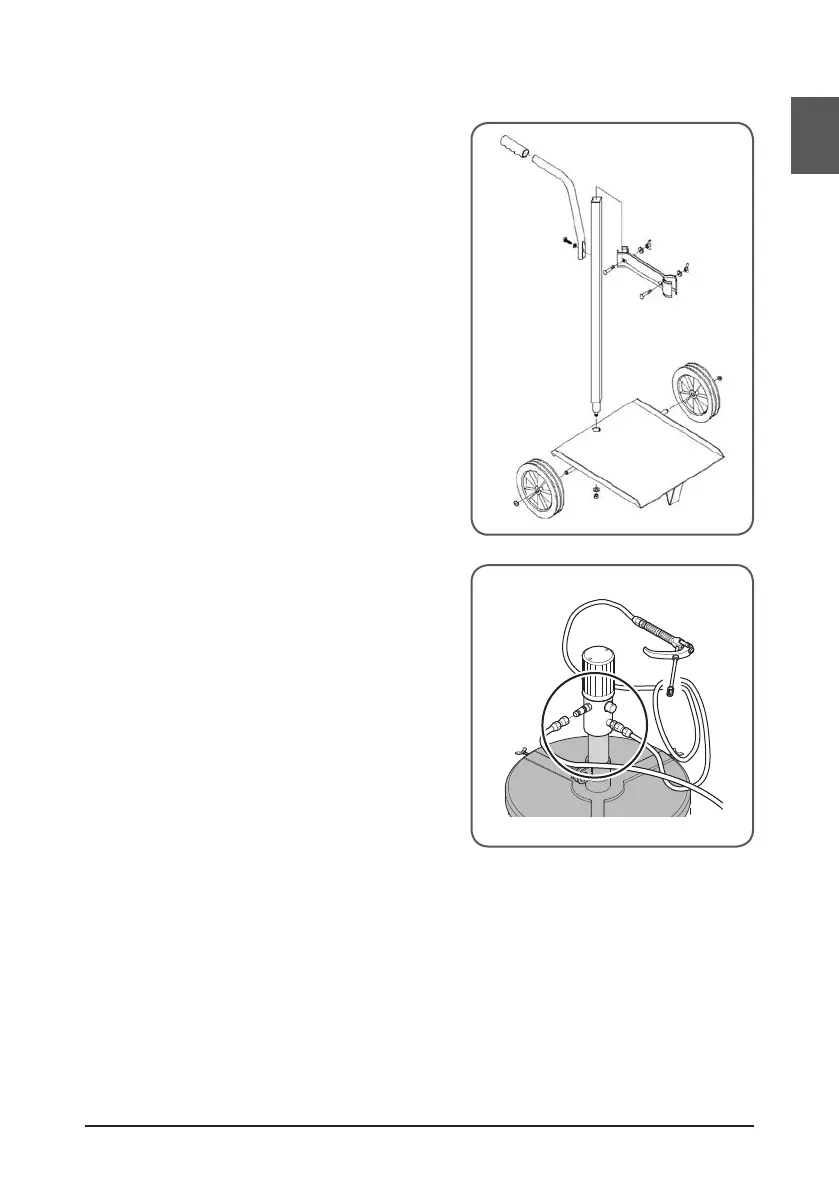

Forallairdrivengreasepumps

1. Connectthegreasedeliveryhose

tothegreasepump.

2. Checkthatalloftheconnections

areattachedsecurely.

3. Checkthatnoneofthehosesare

damaged.Replaceanydamaged

hosesimmediately.

4. Connecttheairinlethosetothequick-

connectionnippleonthegreasepump.

Ensurethattheinletairpressuredoes

notexceed8bar(120psi).Installation

ofanairpressureregulatorontheair

inletisrecommendedtoincreasethe

workinglifeofthegreasepump

mechanism.Thegreasepumpmustbe

connectedtoacleananddryairsupply.

Anunlteredairsupplycancausethe

pumptostallorstop.

5. Squeezethegreasegunhandleuntil

greaseisdischargedfromtheoutlet.

Alloftheairhasnowbeenremoved

andthegreasepumpisreadyforuse.

5. Afteruse

ForLAGG18AE,LAGG50AEandLAGG180AEonly

1. Disconnecttheairinlethose.

2. Releasethepressurefromthegreasepumpbyoperatingthegreasegunhandle.

3. Transferanypossiblegreaseresiduetothenextgreasedrum.

4. Disposeofwastegreaseinanenvironmentallyfriendlymanner.

English

Loading...

Loading...