23

0°-45°

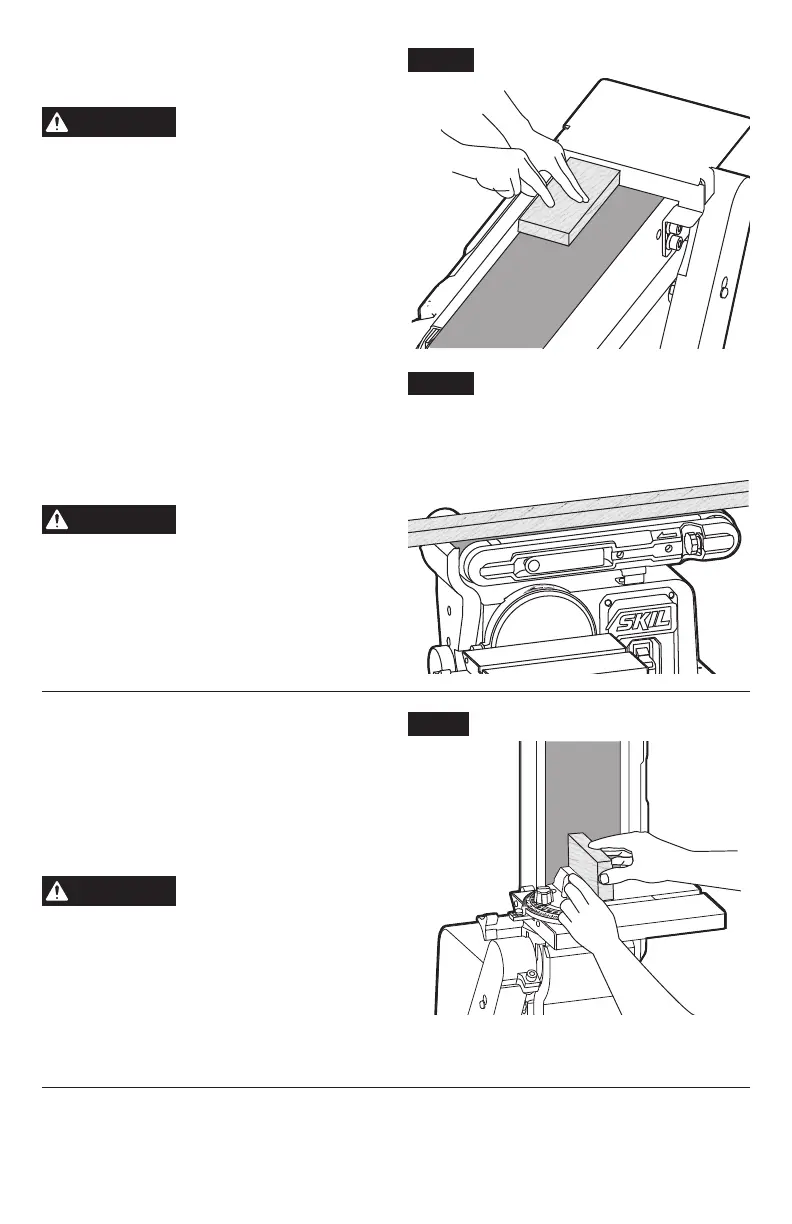

Surface sanding on the sanding

belt (Fig. 15a & 15b)

WARNING

To avoid injury from slips,

jams, or thrown pieces,

adjust the work support to clear the sand-

ing surface by no more than 1/16” (1.6 mm).

When checking clearance between the belt

and work support, press the belt at against

the metal beneath it.

1. Hold the work piece rmly with both hands,

keeping ngers away from the sanding belt

(Fig. 15a).

2. Keep the end closely against the work

support and move the workpiece evenly

across the sanding belt. Use extra caution

when sanding very thin pieces.

3. Apply only enough pressure to allow the

sanding belt to remove some material.

4. When sanding long pieces, remove the work

support (Fig. 15b).

WARNING

The sanding belt is de-

signed to rotate down

towards the table. Avoid kickback by feeding

workpieces against the direction of rotation of

the sanding belt.

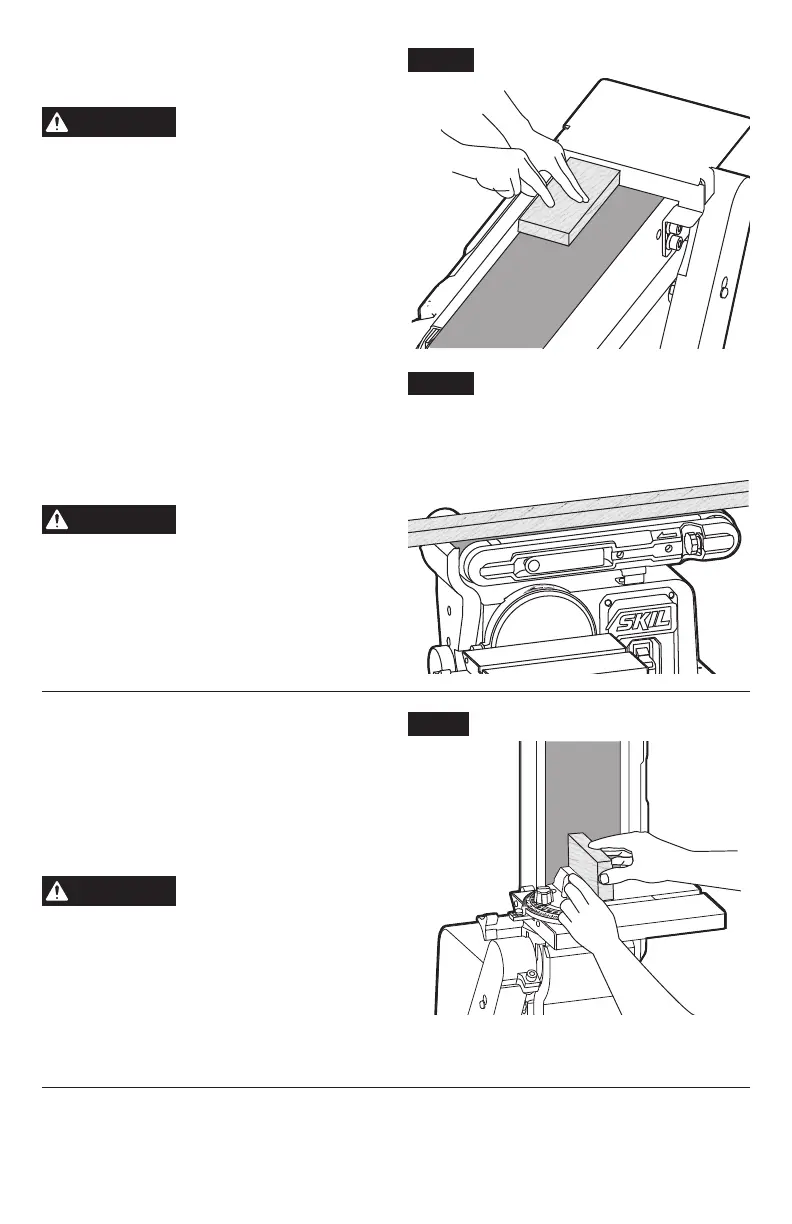

End sanding on the sanding belt

(Fig. 16)

1. It is more convenient to sand the ends of

long workpieces with the sanding belt in a

vertical position.

2. Move the work evenly across the sanding

belt. For accuracy, use the miter guide.

WARNING

To avoid trapping the

workpiece or ngers

between the table and sanding surface, the

table edge should be no more than 1/16"

(1.6 mm) from sanding surface.

Note:

The belt/disc sander can sand both

vertically and horizontally. Depending on the

workpiece, use the work support for horizontal

sanding operations and use the work table for vertical sanding operations.

Fig. 15a

Fig. 15b

Fig. 16

Loading...

Loading...