How to troubleshoot a Skutt 1027 Ventilation Hood that is not operating?

- JJennifer BullockAug 7, 2025

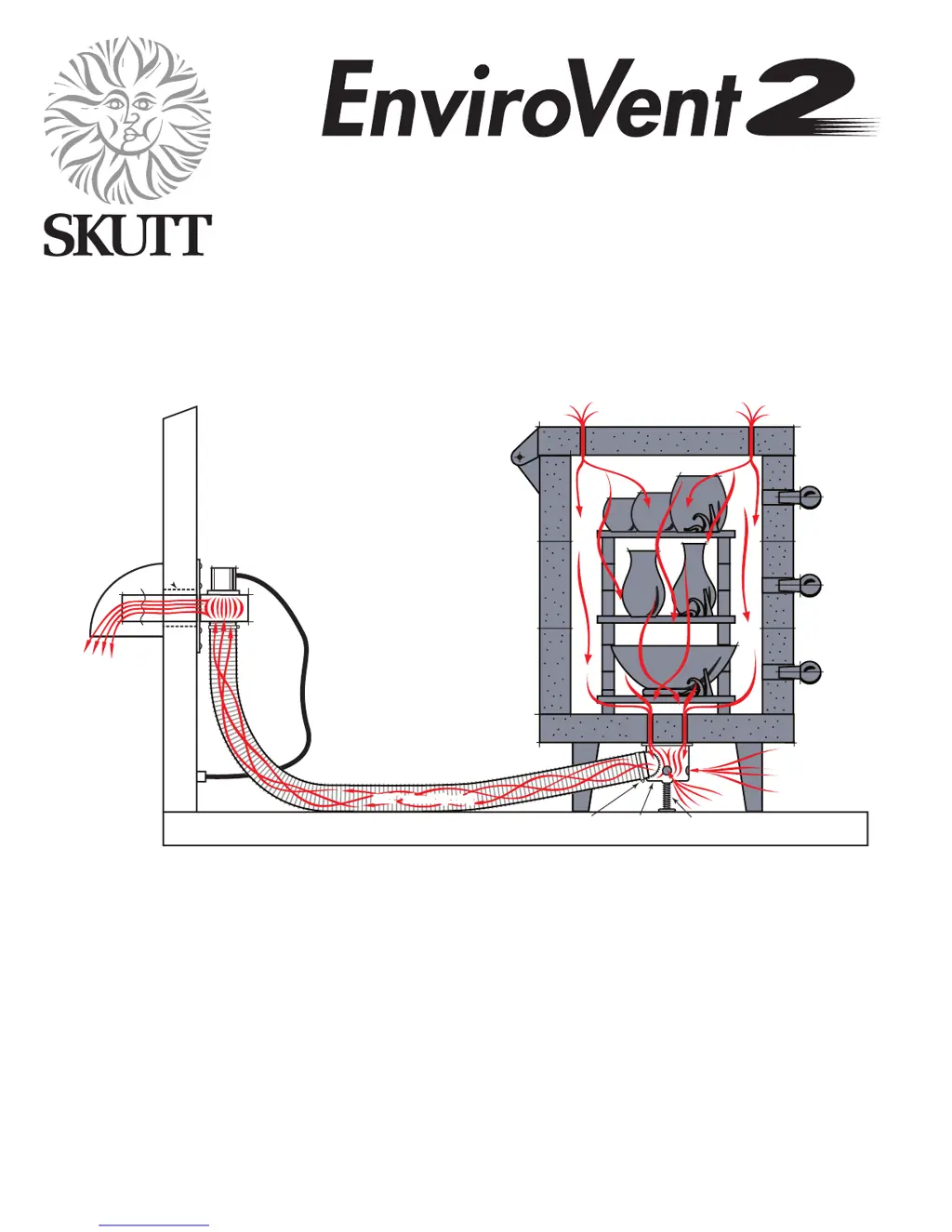

If the Skutt Ventilation Hood is not operating, first, ensure it's properly plugged in and the in-line switch is turned on. Then, verify that the outlet has power. If the outlet lacks power, inspect the breaker.