Page 24 December 2007

SJ 86T

It is the responsibility of the operator to read, completely understand and follow all instructions and warnings

contained in this operating manual and on the MEWP.

FAMILIARIZATION

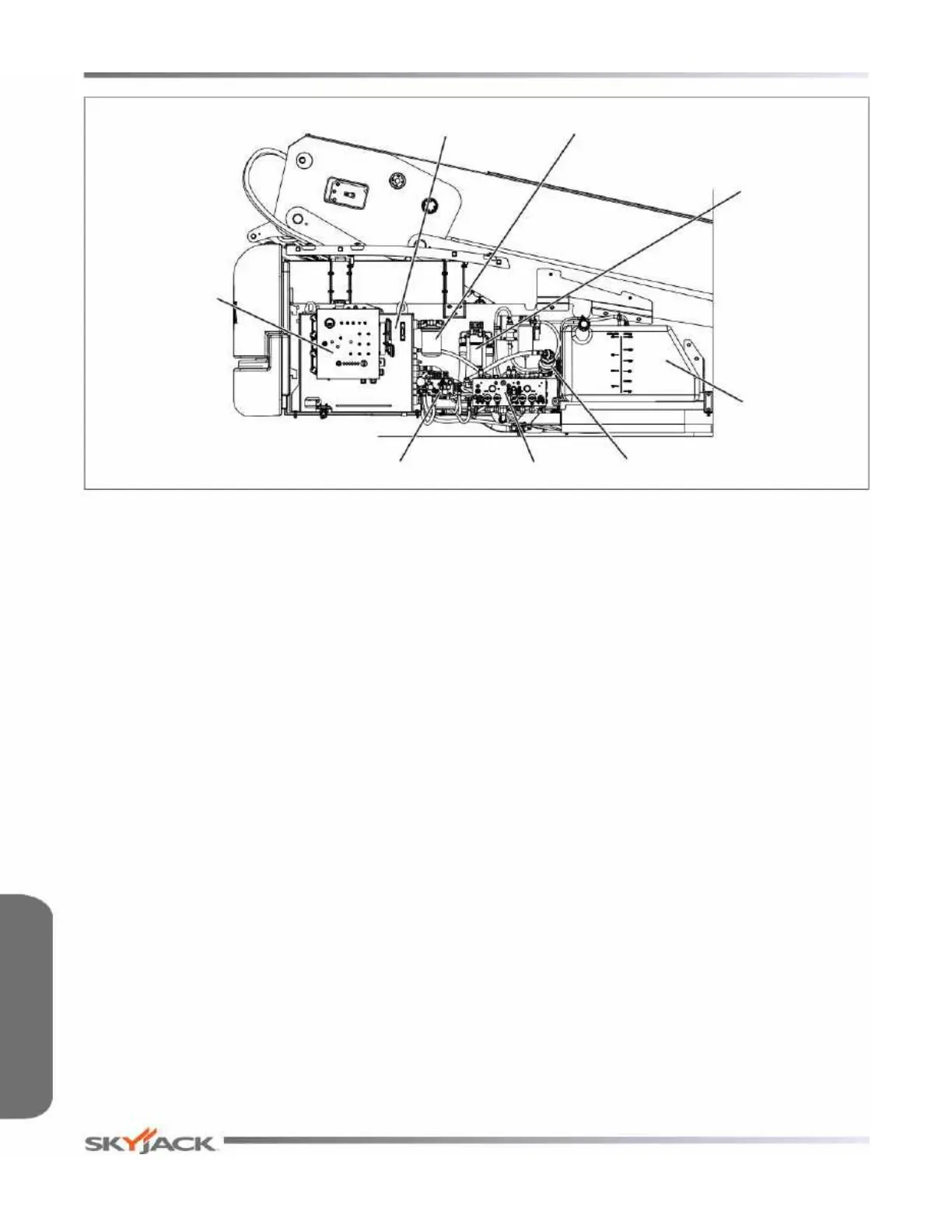

2.3-6 Control Compartment

- Ensure all compartment latches are

secure and in proper working order.

• Base Control Console

- Ensure all switches are returned to their

neutral positions.

- Ensure there are no loose or missing

parts and there is no visible damage.

• Hydraulic Tank

- Ensure hydraulic ller cap is secure.

- Ensure tank shows no visible damage

and no evidence of hydraulic leakage.

• Hydraulic Oil

- Be sure that the boom is in the stowed

position, and then visually inspect the

sight gauge located on the side of the

hydraulic oil tank.

- The hydraulic oil level should be between

the minimum and maximum marks on

the sight glass. Add oil as needed. Refer

to Table 4.2b for recommended oil type.

• Hydraulic Return Filter

- Ensure lter element is secure.

- Ensure there are no signs of leakage or

visible damage.

• High Pressure Filter

- Ensure housing is secure and shows no

visible damage or leakage.

• Brake and Main Manifolds

- Ensure all ttings and hoses are properly

tightened and there is no evidence of

hydraulic leakage.

- Ensure there are no loose wires or

missing fasteners.

• Emergency Power Unit

- Ensure there are no loose or missing

parts and there is no visible damage.

- Ensure there are no loose wires or

missing fasteners.

- Ensure all ttings and hoses are properly

tightened and there is no evidence of

hydraulic leakage.

• Fuel Tank

IMPORTANT

Before using your MEWP ensure there

is enough fuel for expected use.

- Ensure fuel ller cap is secure.

- Ensure tank shows no visible damage

and no evidence of fuel leakage.

Base Control

Console

Fuel Tank

Brake Manifold

Hydraulic Tank

Emergency Power Unit

Main Manifold

Hydraulic Return Filter

High Pressure

Filter

Control Compartment

Visual & Maintenance Inspection Section 2 - Familiarization

Loading...

Loading...