5.8 MOTION ASSEMBLY

The motion assembly provides for both the oscillating motion of the SkyTracker and mount-

ing support for the lamphouse. The assembly consists of a “bent shaft”, shaft seal, drive

pulley, and lower & upper bearings. Bearings within the assembly are permanently lubri-

cated and do not require regular maintenance.

5.9 DRIVE CHAIN TENSION ADJUSTMENT

The drive chain may loose tension over time and need adjustment. To adjust the drive ten-

sion, loosen the four bolts holding the gear reduction motor to the system frame, DO NOT

remove.Applypressuretothemotoruntildeectionofthechainislessthan¼"(6mm)

when force is applied midway between the drive pulley and the motor pulley. After achiev-

ing proper tension, tighten the four motor mounting bolts.

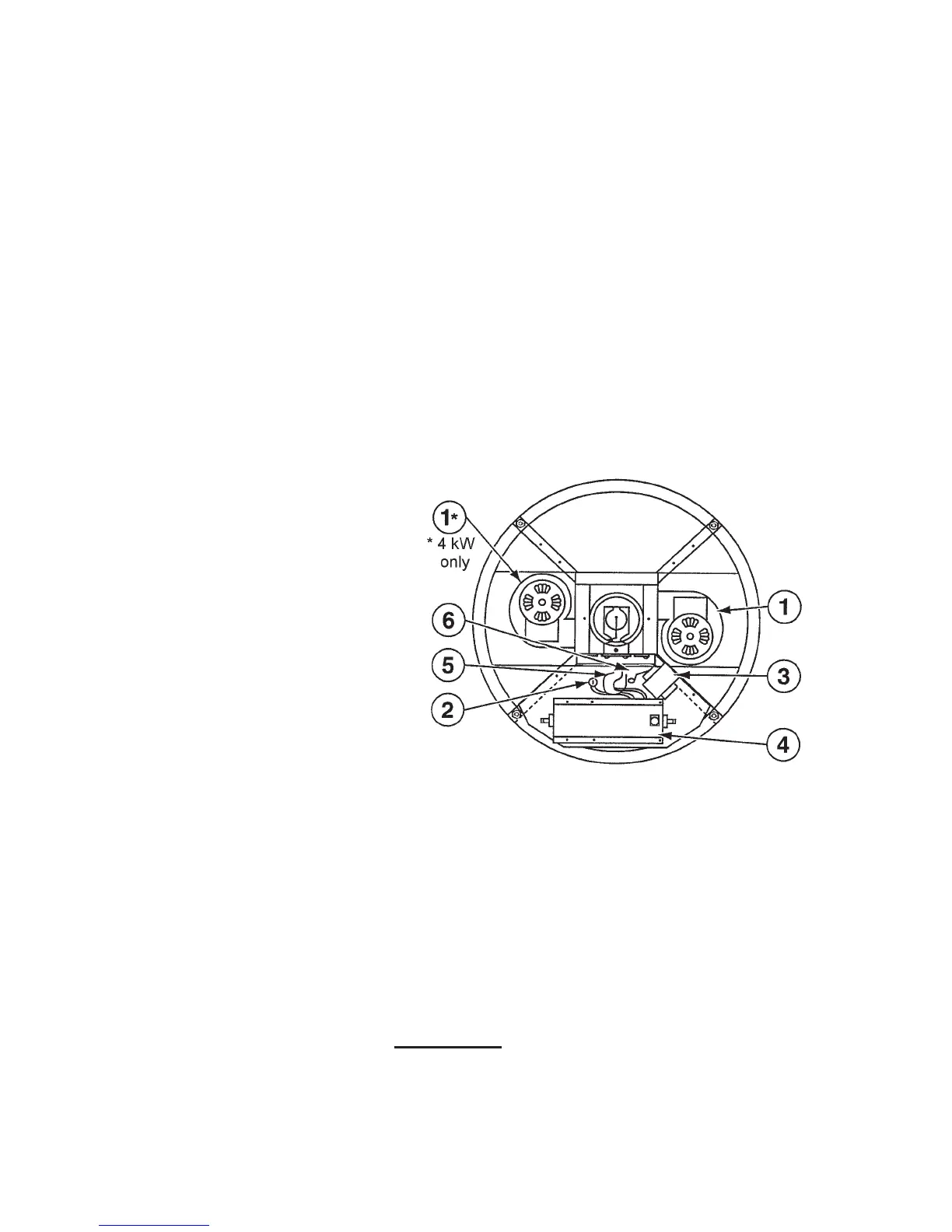

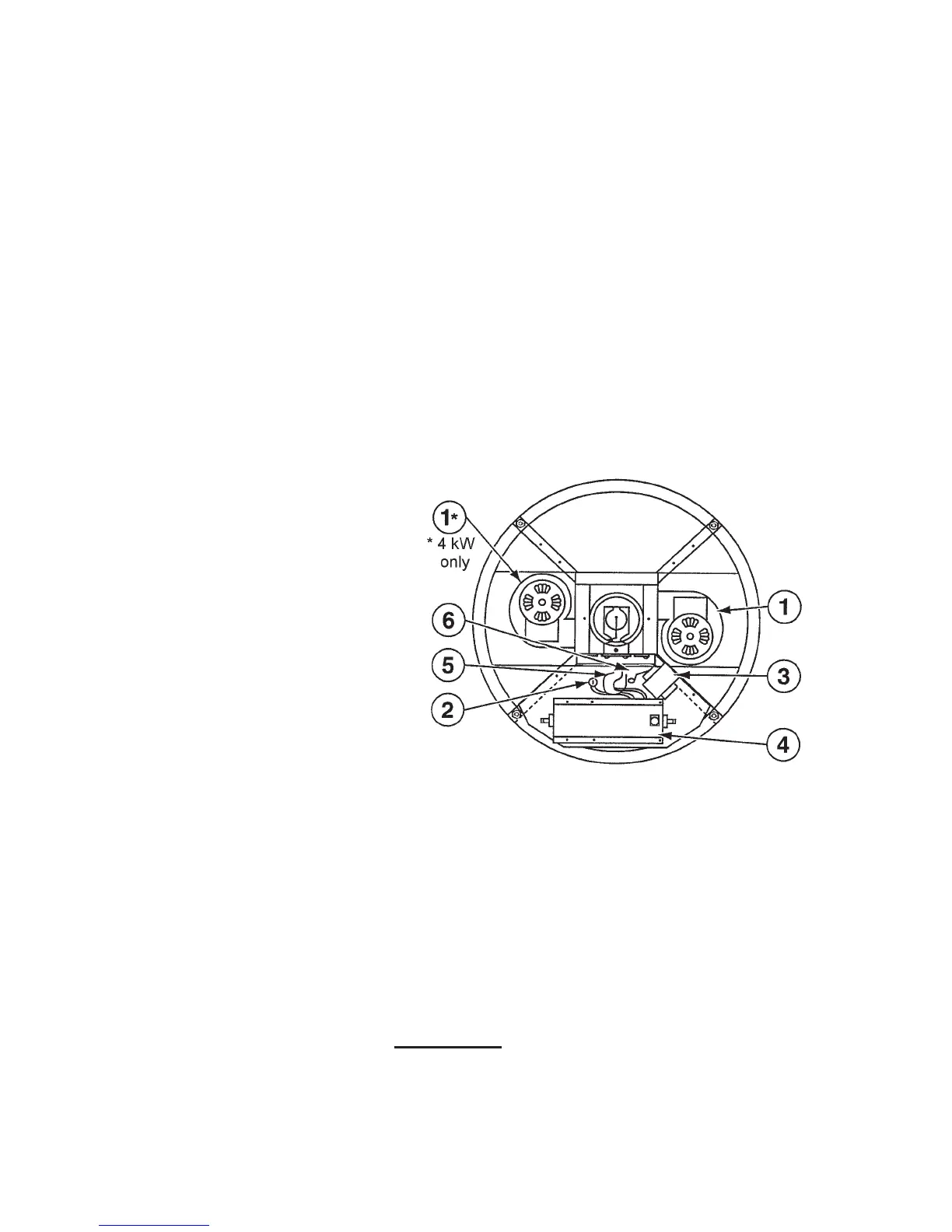

6.0 LAMPHOUSE ELECTRICAL COMPONENTS (2 & 4 kW Models)

1. Blower(s)

2. Spark Gap

3. Primary Transformer

4. R.F. Igniter Transformer

5. Doorknob Capacitor

6. R.F. Trap

LAMPHOUSE BASE PLATE

ELECTRICAL COMPONENTS

FIGURE 8

All high voltage igniter components,

cooling blower(s), thermal switch, and

DC power connectors to the xenon bulb

are located in the lamphead

(see Figures

8 & 9). The functions of the various com-

ponents are as follows:

6.1 IGNITER SYSTEM

The complete high voltage igniter circuit-

ry is located on the lamphead base plate.

To gain access to the internal electrical

components, it is only necessary to un-

latch the two draw-down latches located

at the bottom of the housing. Then, slide

theberglasshousingupwardandaway

from the tubular frame assembly. With

the components exposed, the individual

items that make up the igniter system

can be accessed.

DANGER

Before opening the lamphouse, disconnect all input power to the SkyTracker

so that the igniter cannot be accidentally operated. Severe electrical shock

can result if the igniter is accidentally operated when these parts are exposed.

16

Loading...

Loading...