URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2013 SMC Corporation All Rights Reserved

12 Contacts

AUSTRIA (43) 2262 62280-0

NETHERLANDS

(31) 20 531 8888

BELGIUM (32) 3 355 1464

NORWAY

(47) 67 12 90 20

CZECH REP. (420) 541 424 611

POLAND

(48) 22 211 9600

DENMARK (45) 7025 2900

PORTUGAL

(351) 21 471 1880

FINLAND (358) 207 513513

SLOVAKIA

(421) 2 444 56725

FRANCE (33) 1 6476 1000

SLOVENIA

(386) 73 885 412

GERMANY (49) 6103 4020

SPAIN

(34) 945 184 100

GREECE (30) 210 271 7265

SWEDEN (46) 8 603 1200 HUNGARY (36) 23 511 390

SWITZERLAND (41) 52 396 3131 IRELAND (353) 1 403 9000

UNITED KINGDOM

(44) 1908 563888

ITALY (39) 02 92711

BULGARIA (359) 2 974 4492

ESTONIA (372) 651 0370

ROMANIA

(40) 21 320 5111

LATVIA

(371) 781 77 00

LITHUANIA

(370) 5 264 8126

E

X600-TFR01

This product has no switches for setting, therefore the display cover

should not be opened.

5 Setting

•Parameter Setting

•Hardware Configuration

•I/O Map

•Diagnostic

10 Troubleshooting

Refer to the LED Display. Refer to the operation manual on the SMC

website (URL http://www.smcworld.com).

7 Outline Dimensions (mm)

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com).

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com

).

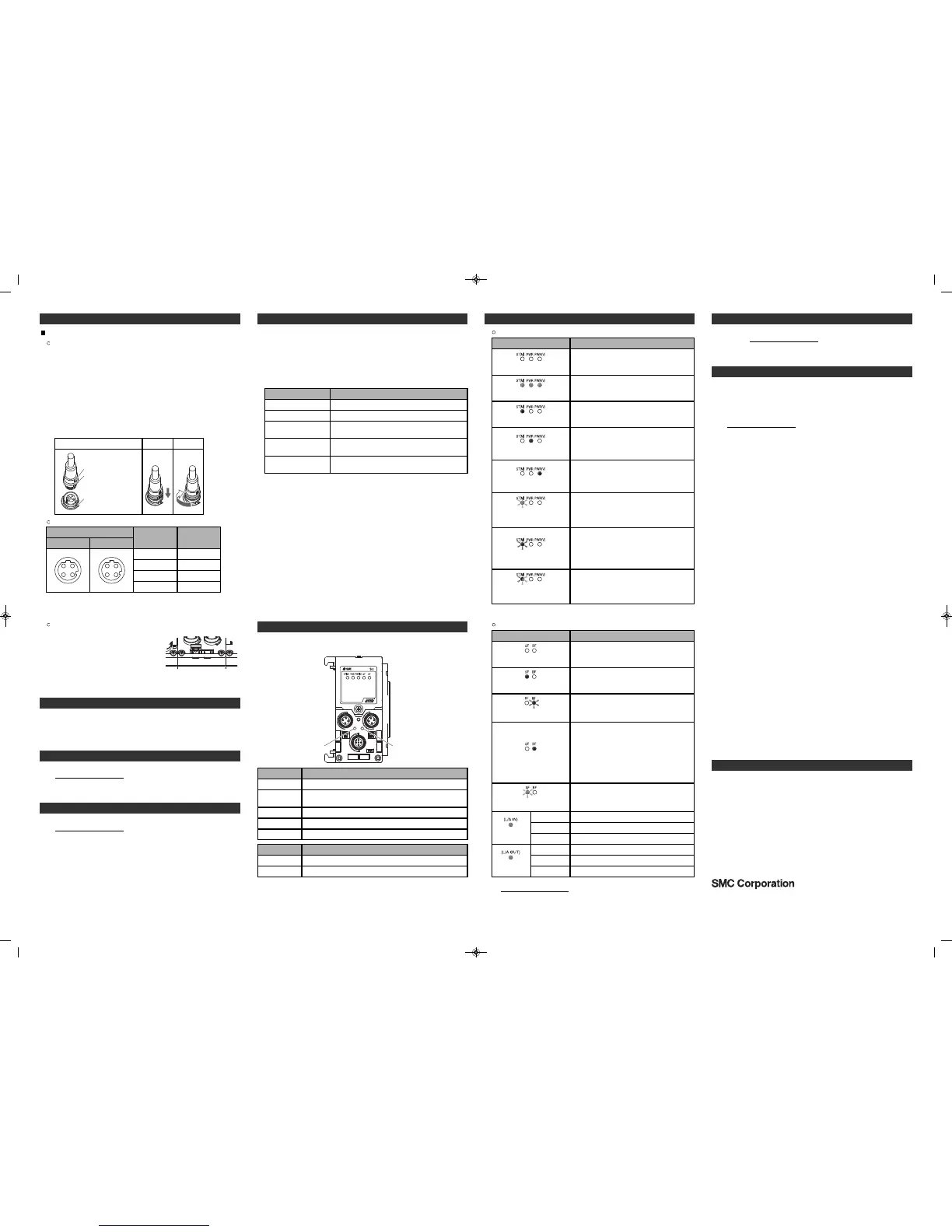

Display

ST(M)

PWR

PWR(V)

SF

Content

Displays the diagnostic status of the unit.

Displays the status of the power supply voltage for control

and input.

Displays the status of the power supply voltage for outputs.

Displays the system status.

BF Displays the communication status.

PROFINET status

Content

The communication with the PLC has been

established normally, or the power supply

for control and input is OFF.

LED display

OFF.

The communication with the PLC has been

established, but a diagnostic error has

occurred.

The SI unit received a Node flashing test

command.

Display

L/A IN

L/A OUT

Content

Displays the communication status of the BUS IN side.

Displays the communication status of the BUS OUT side.

Red SF LED is ON.

The configuration data of the PLC and

EX600 are not consistent.

Either of the following conditions:

•Power supply for the PLC is OFF.

•The cable between the PLC and SI unit is

not connected.

•The PLC or the SI unit is faulty.

•The configuration data of the PLC and the

Device Name of the SI unit are not

consistent.

BUS OUT side: No Link, No Activity

(Green)

BUS OUT side: Link, No Activity

BUS OUT side: Link, Activity

OFF

ON

Flashing

BUS IN side : No Link, No Activity

(Green)

BUS IN side : Link, No Activity

BUS IN side : Link, Activity

OFF

ON

Flashing

9 LED Display

The status display LED displays the power supply and communication

status.

SI unit common status

Content

The power supply for control and input is

OFF.

LED display

OFF.

The unit is in normal operation.

Green LEDs are ON.

An internal memory error has occurred in

the SI unit.

Red ST(M) LED is ON.

The power supply voltage for control and

input is abnormal.

(Control and input power supply voltage

monitoring parameter is valid)

Red PWR LED is ON.

The power supply voltage for outputs is

abnormal.

(Output power supply voltage monitoring

parameter is valid)

Red PWR(V) LED is ON.

A unit other than the SI unit has been

detected.

Green ST(M) LED is

flashing.

Either of the following conditions:

•The valve ON/OFF counter has exceeded

the set value.

•The valve is short circuited or

disconnected.

Red ST(M) LED is flashing.

Connection error between units has

occurred.

Red/Green ST(M) LED is

flashing alternately.

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com).

Red BF LED is flashing.

Red BF LED is ON.

Green SF LED is flashing.

8 Maintenance

Turn OFF the power supply, stop the supplied air, exhaust the residual

pressure and verify the release of air before performing maintenance.

9 LED Display (continued)

6 How to order

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com).

4 Installation (continued)

Connector pin assignment

TD+

Signal name

RD+

TD

-

1

Pin number

2

(2)

(3)

W

iring

Connect the M12 connector cable.

The M12 SPEEDCON connector connection method is explained

below.

(1)Align mark B on the metal bracket of the cable connector

(plug/socket) with mark A.

(2)Align with mark C on the unit and insert the connector vertically.

If they are not aligned, the connector cannot be connected

correctly.

(3)When mark B has been turned 180 degrees (1/2 turn), wiring is

complete. Confirm that the connection is not loose. If turned too

far, it will become hard to remove the connector.

Mounting the marker

The signal name of the input or output

devices and unit address can be written

to the marker, and can be installed to

each unit.

Mount the marker (EX600

-

ZT1) into the

marker groove as required.

3

11 Commissioning

Cleaning method

Use a soft cloth to remove stains.

For heavy stains, use a cloth soaked with diluted neutral detergent and

fully squeezed, then wipe up the stains again with a dry cloth.

Do not use solvents such as benzene, thinner etc. to clean each unit.

Inspection item

Connector/wiring

Seal cap

Screws for mounting

and installation

Connection cables

Content of inspection

If the connector is loose, tighten it correctly.

If the seal cap is loose, tighten it correctly.

If the screws are loose, tighten according to the

specified torque.

If the cable is damaged or has any visual

abnormality, replace the cable.

Supply voltage

Check that the supply voltage is within

specification (24 VDC ±10%).

How to reset the product for power cut or forcible de-energizing

Supply power to the product.

The output status from just before the power was disconnected will not be

maintained when the power supply is recovered.

Start operation of the product after confirming the safety of the entire

system.

Loading...

Loading...