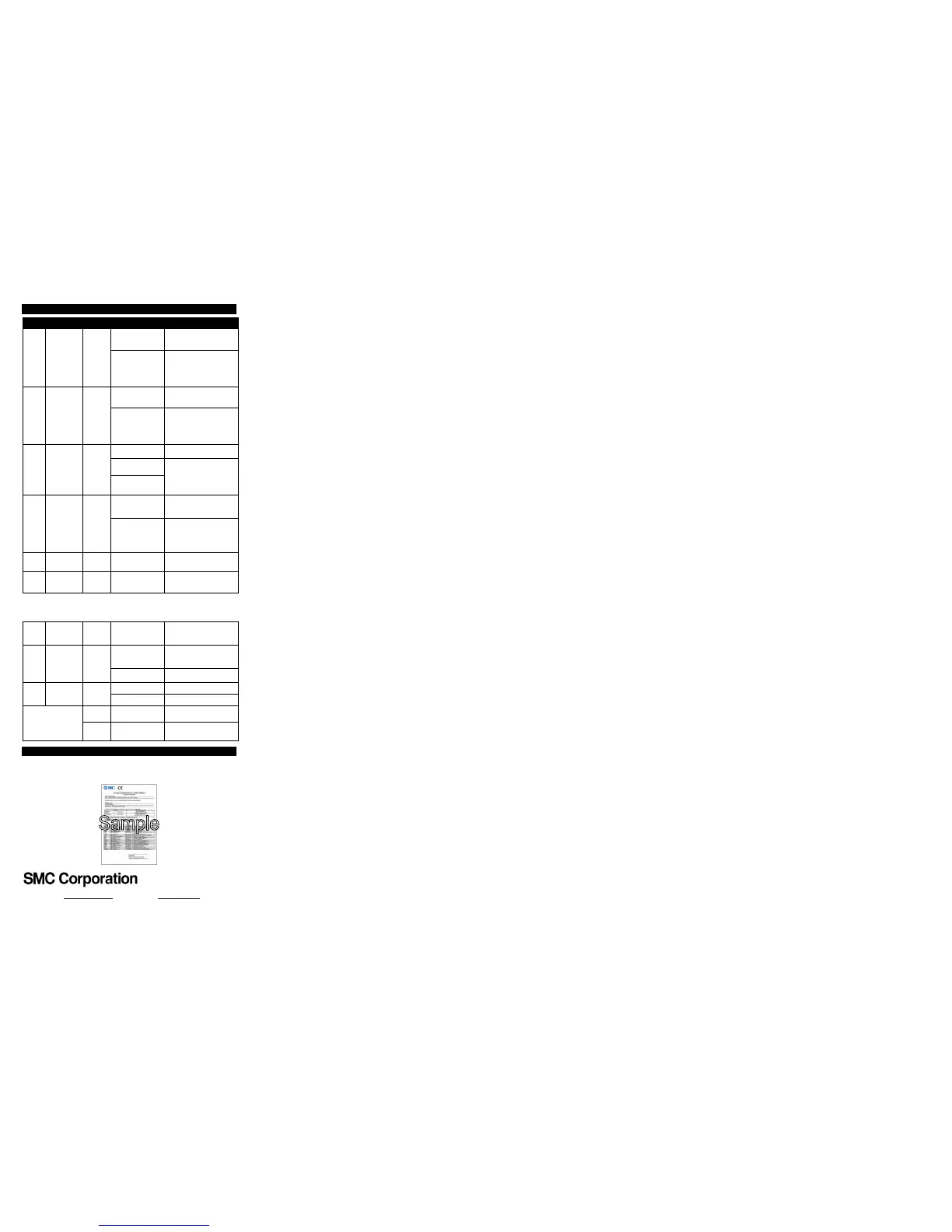

10 Troubleshooting Continued

Internal temp.

sensor

High temp.

failure

Internal temp. sensor

value exceeds the high

temp. cutoff

temperature.

Check the set value for high

temp. cutoff temperature and

confirm the temperature really

reaches this value.

Flow rate of circulating

fluid is zero.

If the flow rate of the circulating

fluid is zero, the temperature of

circulating fluid can’t be

detected and might increase.

Confirm the flow of circulating

fluid is not stopped by valves

etc.

Internal

temp. sensor

Low temp.

failure

Internal temp. sensor

value is lower than low

temp. cutoff

temperature.

Check the set value for low temp.

cutoff temp. and confirm the

temperature really reaches this

value.

Flow rate of circulating

fluid is zero.

If the flow rate of the circulating

fluid is zero, the temperature of

circulating fluid can’t be

detected and might decrease.

Confirm the flow of circulating

fluid is not stopped by valves

etc.

Facility water temp is

high.

Decrease facility water temp. and

increase a flow rate.

If flow rate of circulating fluid is

zero, the temperature of

circulating fluid cannot be

measured and the temperature

of heat exchanger may

increase. Ensure the circulating

fluid is allowed to flow.

Cooling or heating

capacity overload.

No temperature decrease when

100% cooling output.

No temperature increase when

100% heating output.

Volume of circulating

fluid is too large.

If the volume of circulating fluid

system is too large, the change

of temperature takes a long

time. In this case, change

overload judging time setting to

avoid this alarm. (Refer to 6.3.2)

Low circulating

flow rate alarm

(Option)

The flow rate of the

circulating fluid is 1

L/min. or less

Investigate why the flow rate

of the circulating fluid is low

and take countermeasures.

Internal

temp. sensor

disconnectio

n alarm

High level noise

entered the temp.

sensor line.

Check whether unstable

temperature is caused by

noise. Please consult SMC if it

is caused by noise.

External

temp. sensor

disconnectio

n alarm

The external temp.

sensor is not

mounted.

For learning control or

external tune control, be sure

to mount the external temp.

sensor.

Abnormal auto

tuning alarm

Capacity of

circulating fluid is too

large.

Adjust PID value (proportional

band, integral time and

derivative time) of setting

mode Level 2 by hand.

Overloaded during

auto tuning mode

Fluid level of tank is

not enough.

Check all fluid connections

connected with the product.

Temperature rises and

falls +/-1 to 2 C

gradually about the set

point temperature.

Flow rate of

circulating fluid is

low.

Keep the flow rate 3L/min or

more.

PID parameters are

set incorrectly.

If the temperature cannot be

stable at default value,

perform auto tuning.

11 Declaration of Conformity

Below is a sample Declaration of Conformity(DoC) used for this product.

An actual DoC will be supplied with each product.

http// www.smcworld.com (Global) http// www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2017 SMC Corporation All Rights Reserved.

Loading...

Loading...