10

QUICK START GUIDE cont'd

Select the wire material, wire size and shielding gas to be

used. Return to the main menu by pushing the knob for

at least 2 seconds.

3- SET THE THICKNESS OF THE METAL BY TURNING

KNOB

B

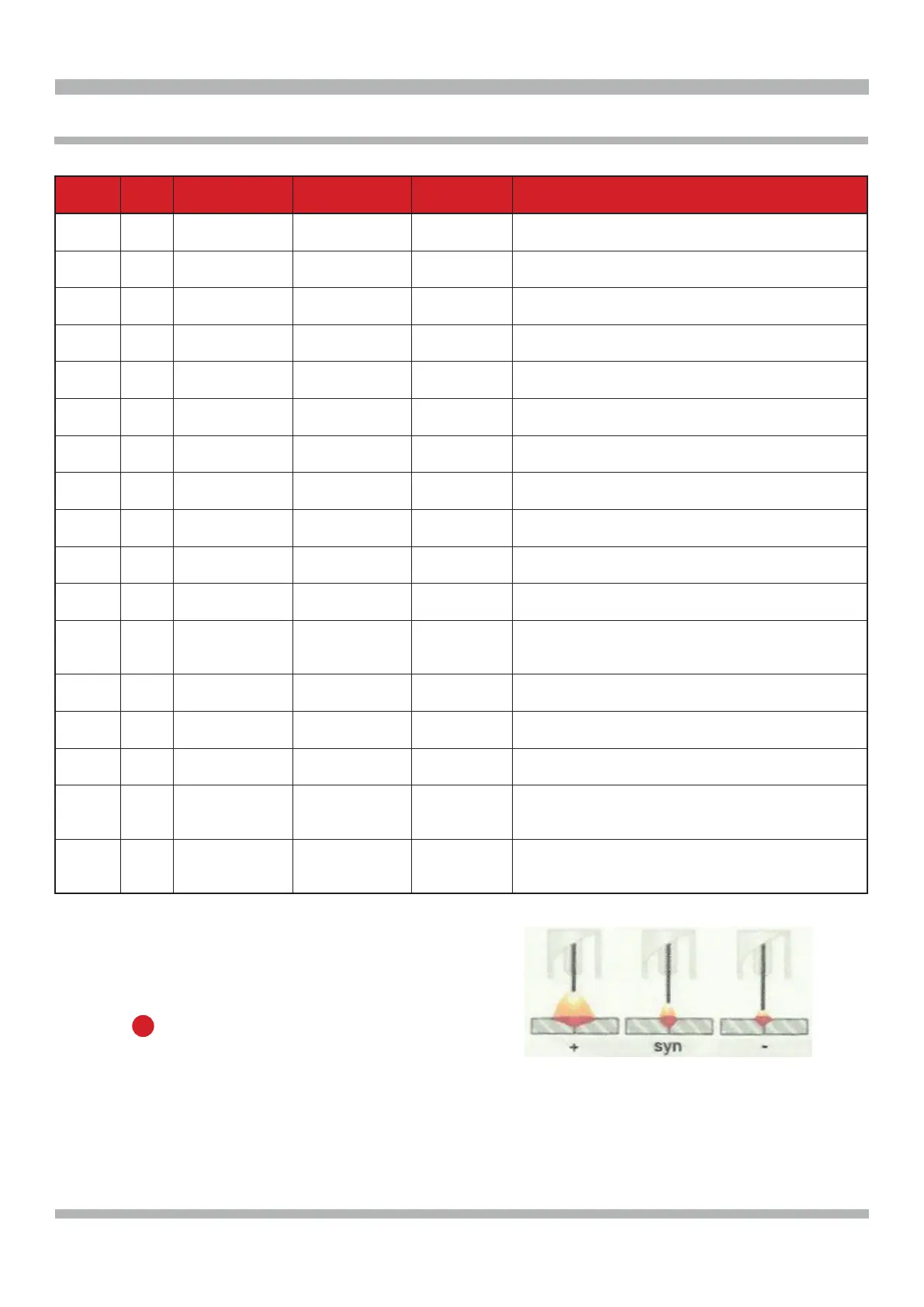

4- ADJUSTING THE WELDING VOLTAGE (ARC

LENGTH)

If the wire tends to disappear within the gas nozze while

you would like to see its length, for instance to easily

reach corners or to direct it where you wish, then we need

to shorten the arc by setting it to a lower value of voltage,

thus creating a greater stick out.

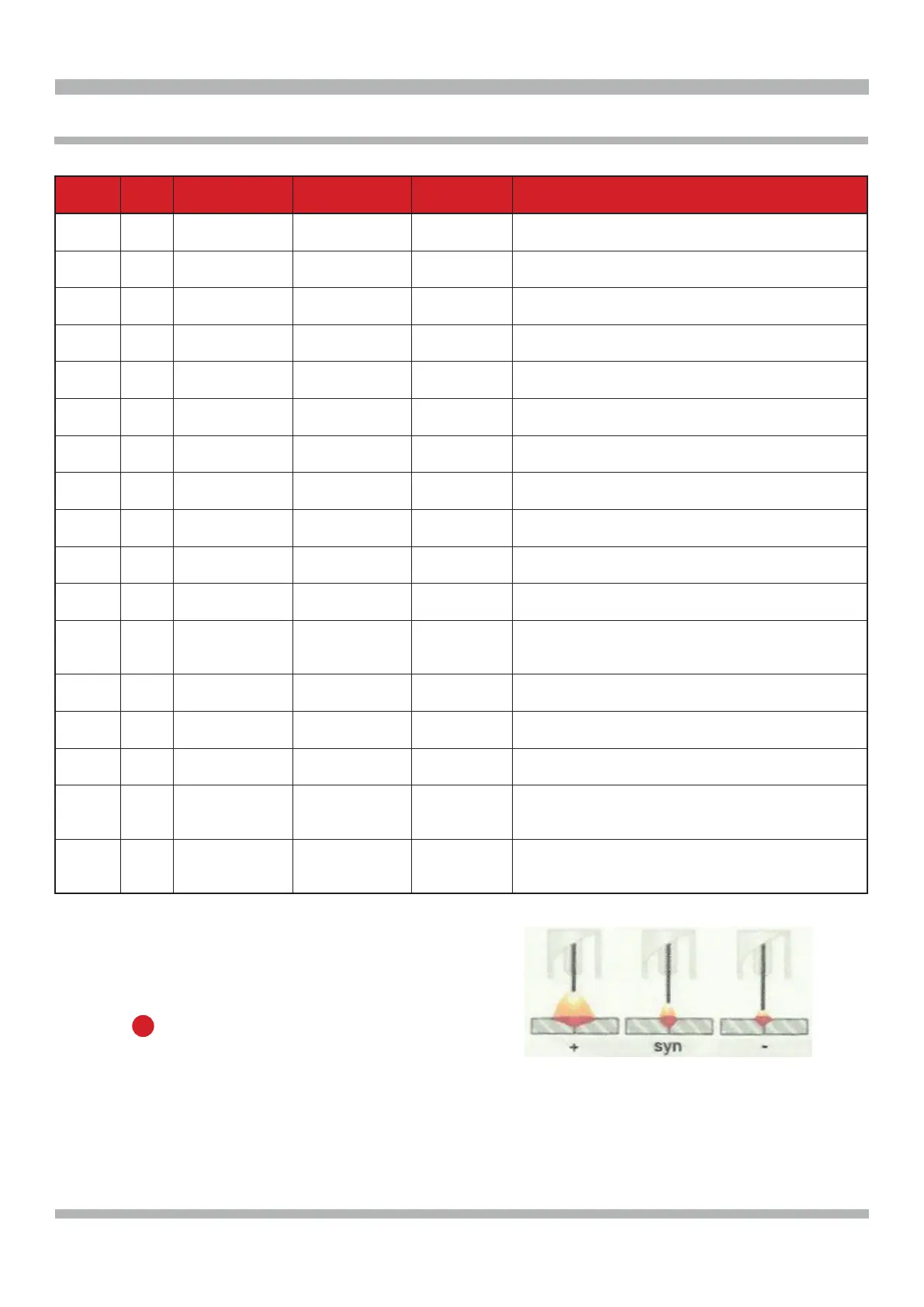

Setting

Wire

Dia

Composition Shielding Gas

Material

Thickness

Application

E71TGS .035 Flux Core -

Steel

none .040 to .200 All-purpose steel welding from sheet metal to

strutural

Fe .023 Steel 75% Argon

25%CO2

.023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .023 Steel 100% CO2 .023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .030 Steel 75% Argon

25%CO2

.023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .030 Steel 100% CO2 .023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .035 Steel 75% Argon

25%CO2

.023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .035 Steel 100% CO2 .023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .040 Steel 75% Argon

25%CO2

.023 to .200 All-purpose steel welding from thin sheet to

strutural

Fe .040 Steel 100% CO2 .023 to .200 All-purpose steel welding from thin sheet to

strutural

308L .030 Stainless-Steel 98% Argon

2% CO2

.030 to .137 301, 302, 304 and 305 Stainless-Steels

308L .035 Stainless-Steel 98% Argon

2% CO2

.030 to .137 301, 302, 304 and 305 Stainless-Steels

AlMg5

5356

.035 Aluminum

Magnesium 5%

100% Argon .030 to 0.240 All-purpose, automotive body panel and struc-

tural repair, pressure vessels boats and truck

bodies

AlMg5

5356

.040 Aluminum

Magnesium 5%

100% Argon .030 to 0.240 All-purpose, automotive body panel and structu-

ral repair, pressure vessels boats and truck bodies

AlSi12

4047

.035 Aluminum

Silicon 12%

100% Argon .030 to 0.240 Welding forged and cast aluminum parts

AlSi12

4047

.040 Aluminum

Silicon 12%

100% Argon .030 to 0.240 Welding forged and cast aluminum parts

CuSi3

6560

.030 Copper

Silicon 3%

100% Argon .023 to .120 MIG brazing, automotive body panel and structu-

ral repair with high strength, Boron and glavanized

steels

CuSi3

6560

.035 Copper

Silicon 3%

100% Argon .023 to .120 MIG brazing, automotive body panel and structu-

ral repair with high strength, Boron and glavanized

steels

SYNERGIC CURVE (WIRE SELECTION):

Loading...

Loading...