19

Chapter 3 Installation Instructions

1. The machine should be installed on a hard, level concrete surface and its 4 legs should be

mounted over the level pads.

2. Place a level gauge on the top surface of the machine and adjust the screw of the level pads to

let the machine bed be level.

3. Check the hydraulic oil tank to make sure that the level is at 2/3 full. The oil tank capacity is

200 liters. One of the following brand name hydraulic oils or an equivalent class hydraulic oil

should be used.

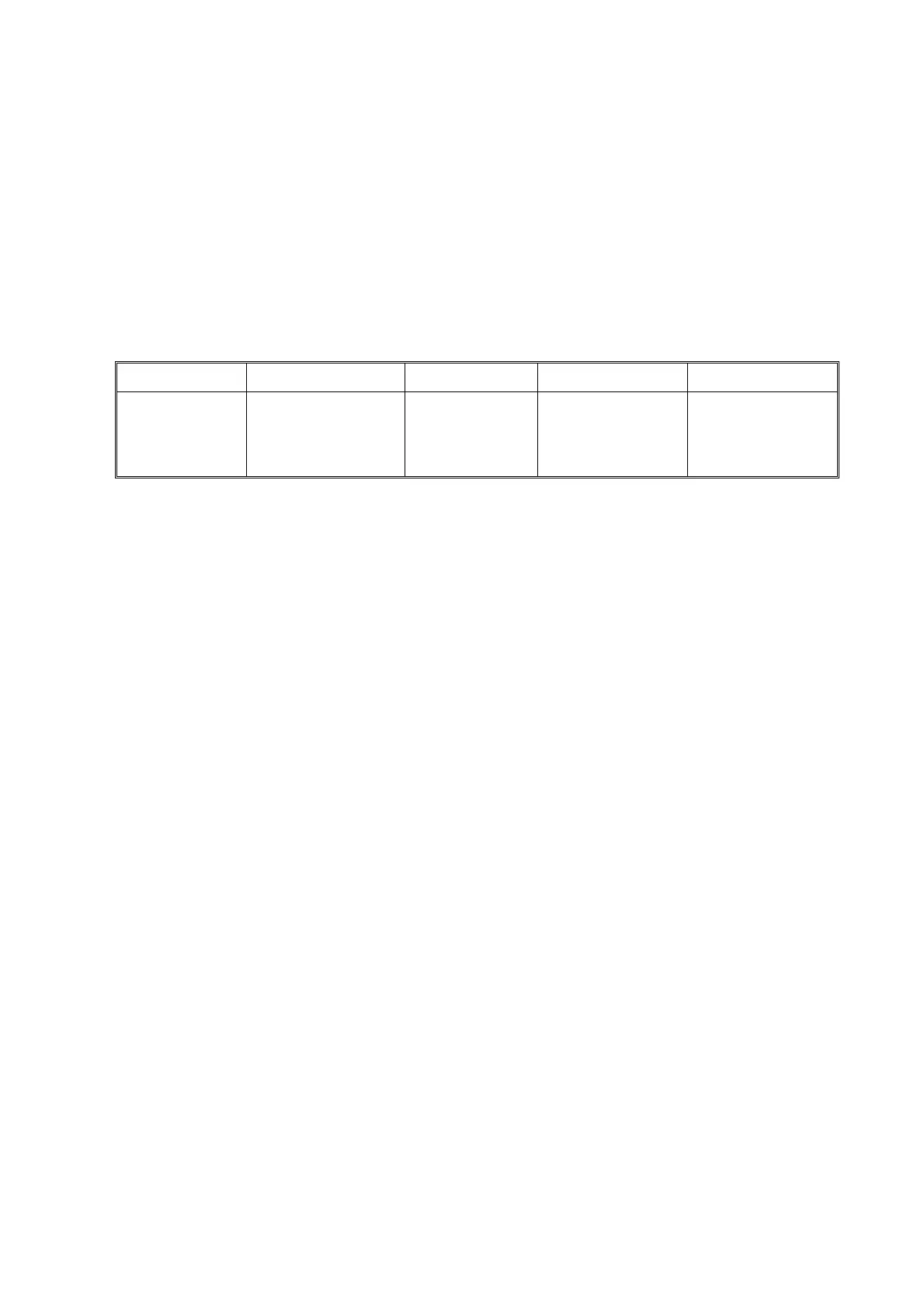

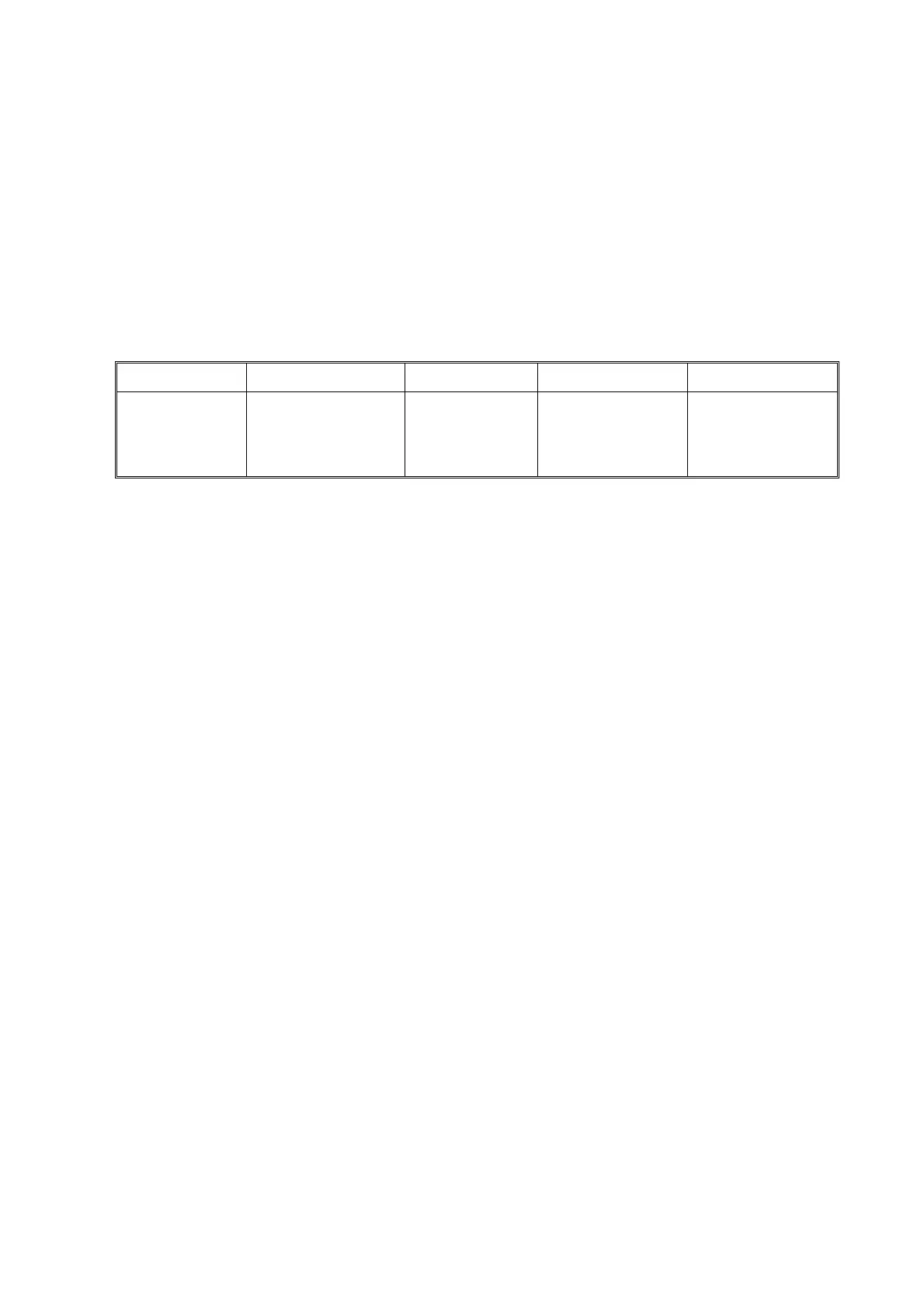

VISCOUTY MITSUBISHI SHOWA MOBIL SHEEL

1 SO, VG46 DIAMOND

HYD.F10001

46

SHOSEKI

JH46

MOBIL DTE

OIL LIGHT

SHELL TERAS

OIL C46

4. First, check and make sure the electrical power supply source follows machine’s requirements.

Use an electric voltage meter to ensure the power source is a stable 3 phase current that does not

vary in voltage by more than 10% (+ or -). We suggest the usage of an electrical power stabilizer

to protect the machine control unit. Make sure to provide a dedicated and secure grounding and

the grounding resistance must be under 50Ω.

Notice: Only qualified electricians should be allowed to connect the electrical power to the

machine.

5. After the power is connected to the machine, turn on the main power switch which is located on

the door of the right electrical box. Then turn the switch of the manual/auto mode selection to

manual mode. Push the button of the pump start/stop to run the pump. (Notice: If push the

button one again, the pump stop.) Then turn the switch of the bending die open/close to open

position and push the safety ensure button simultaneously. So the hydraulic pump will be

engaged. Check if the main hydraulic system pressure gauge has 150 kg/cm

2

pressure. If not,

please stop the pump, turn off the power and switch any two of the power line connections until

the system pressure is engaged. Notice that the main hydraulic system pressure gauge must be

150 kg/cm

2

pressure.

Loading...

Loading...