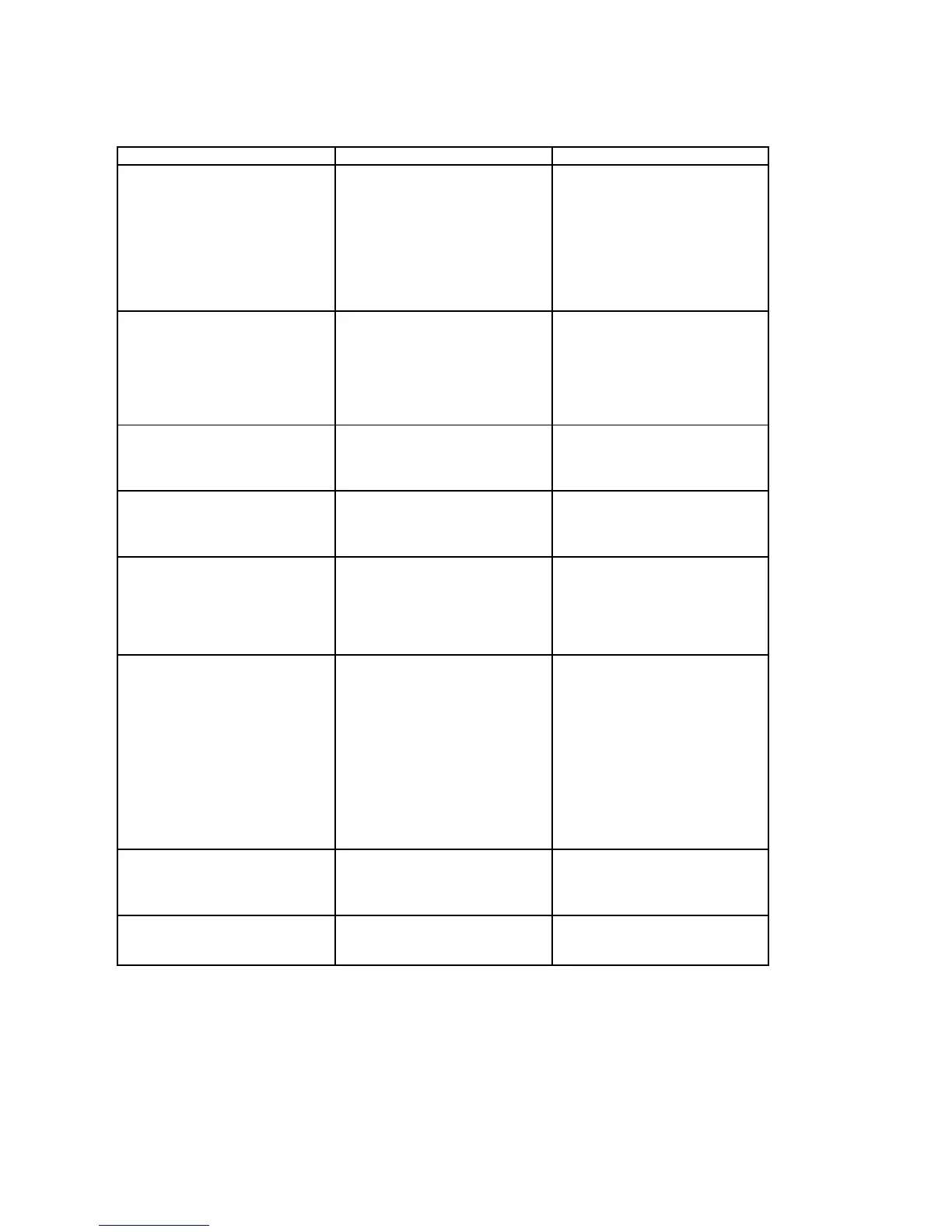

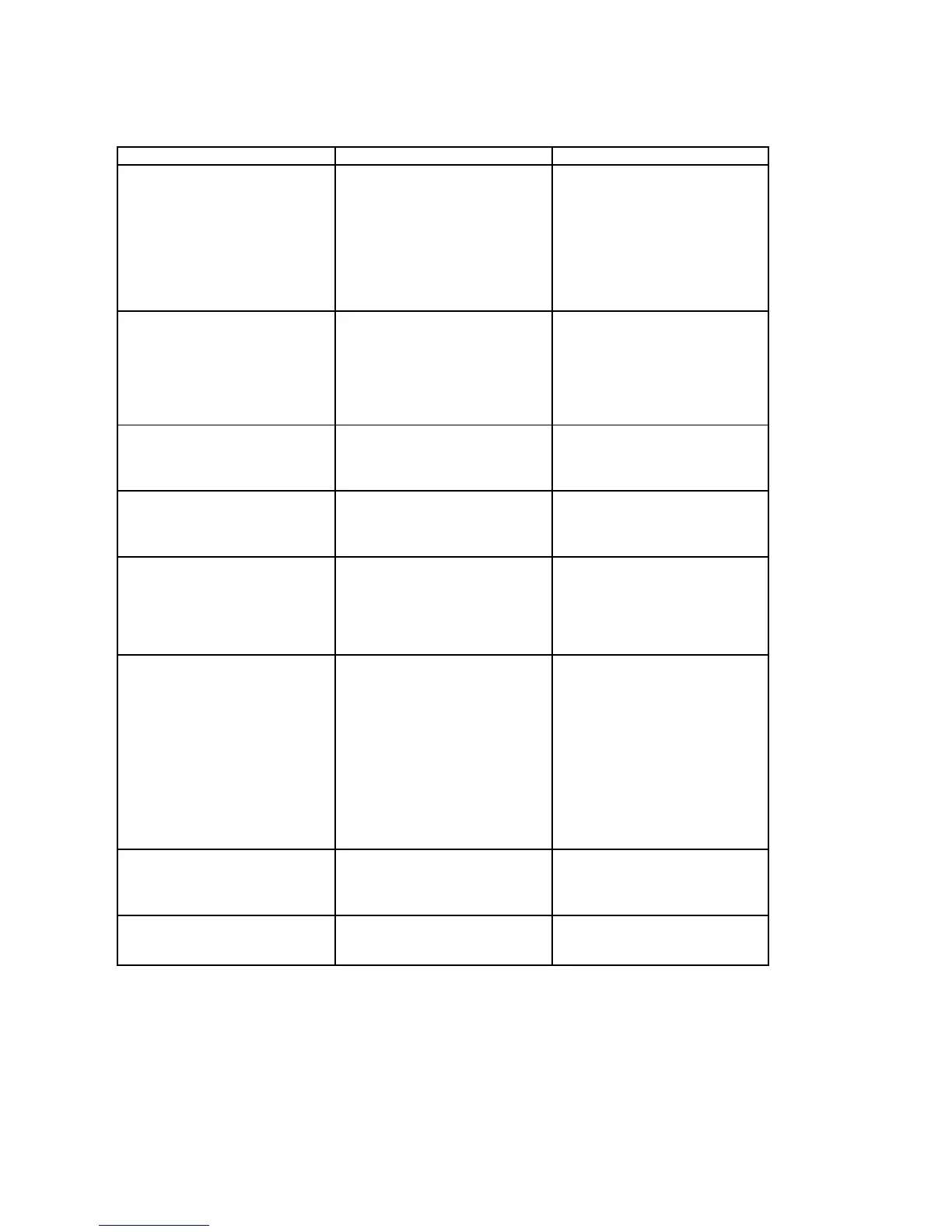

22. TROUBLESHOOTING

The following table illustrates some problems which may arise during operation.

FAULT CAUSE ACTION

Grass ejection insufficient 1. Grass wet

2. Grass too long

3. Cutting height too low

4. Engine speed too low

5. Forward speed too high

6. Build-up of

rass inside flail

housing

1. Wait until the

rass has

dried

2. Go over the

ht

4. Accelerate to maximum

5. Decrease forward speed

6. Clean the inside of the flail

housing

Machine does not cut the

rass

completely

1. Forward speed too high

2. Engine speed too low

3. Grass too long

4. Flails worn or broken

5. Build-up of

rass inside flail

housing

1. Decrease forward speed

2. Accelerate to maximum

3. Go over the

ht

4. Replace the flails

5. Clean the inside of the flail

housing

Machine scalps the ground 1. Cutting height too low

2. Undulating terrain

3. Ground uneven

1. increase the cuttin

.

direction)

3. increase cutting height

Belt slips 1. belt tension inadequate

2. Build-up of

rass inside flail

housing

3. Belt worn

1. Adjust the belt tension

2. Clean the inside of the flail

housing

3. Replace belt

Machine vibrates excessively 1. Build-up of

rass inside flail

housing

2. Belt damaged

3. Flails bent or broken

4. Flail rotor warped

1. Clean the inside of the flail

housing

2. Replace belt

3. Replace flails

4. Replace rotor

En

work

operations

1. Engine speed too low

2. Flails worn

3. Forward speed too high

4. Snarl or build-up of

rass

on rotor

5. Grass too long

6. Cutting height too low

1. Accelerate to maximum

2. Invert or replace flails

3. Decrease forward speed

4. Remove

rass from flail

rotor

5. Go over the

ht

Machine tends to run awa

on

steep banks

1. ground too soft

2. operator cutting at right an-

gles to bank

1.wait until ground dries

2. work in direction of bank

The cutting unit projects ob-

jects outwards

1. front guard raised

2. front cover open

3. working in reverse gear

1.lower the front guard

2. close front cover firmly

3.only work in forward gear

ENGINE

Loading...

Loading...