15. MAINTENANCE AND STORAGE

! All operations on the machine must be carried out exclusively by authorized

personnel.

! Always switch off the engine when checking, adjusting or servicing the ma-

chine.

! Allow the machine to cool down before inspection.

! The belt guard (Fig. 9 ref. D) and flail guards ( Fig. 1 ref. F) must always be

correctly installed and intact. If they become damaged, have them repaired

before the machine is used again.

! Make sure that all the guards of rotating and moving parts are in place.

! For greater safety, when replacing the flails replace all the fixing screws and

nuts at the same time, as described in section 14, point D.

! Inspect the fuel lines. These should be replaced if damaged or after a maxi-

mum of three years, along with the fixing bands. Old lines may leak fuel.

! Check and regularly adjust the forward clutch control, blade clutch control,

brakes, accelerator and crawl/high speed gear selector lever and gear lever.

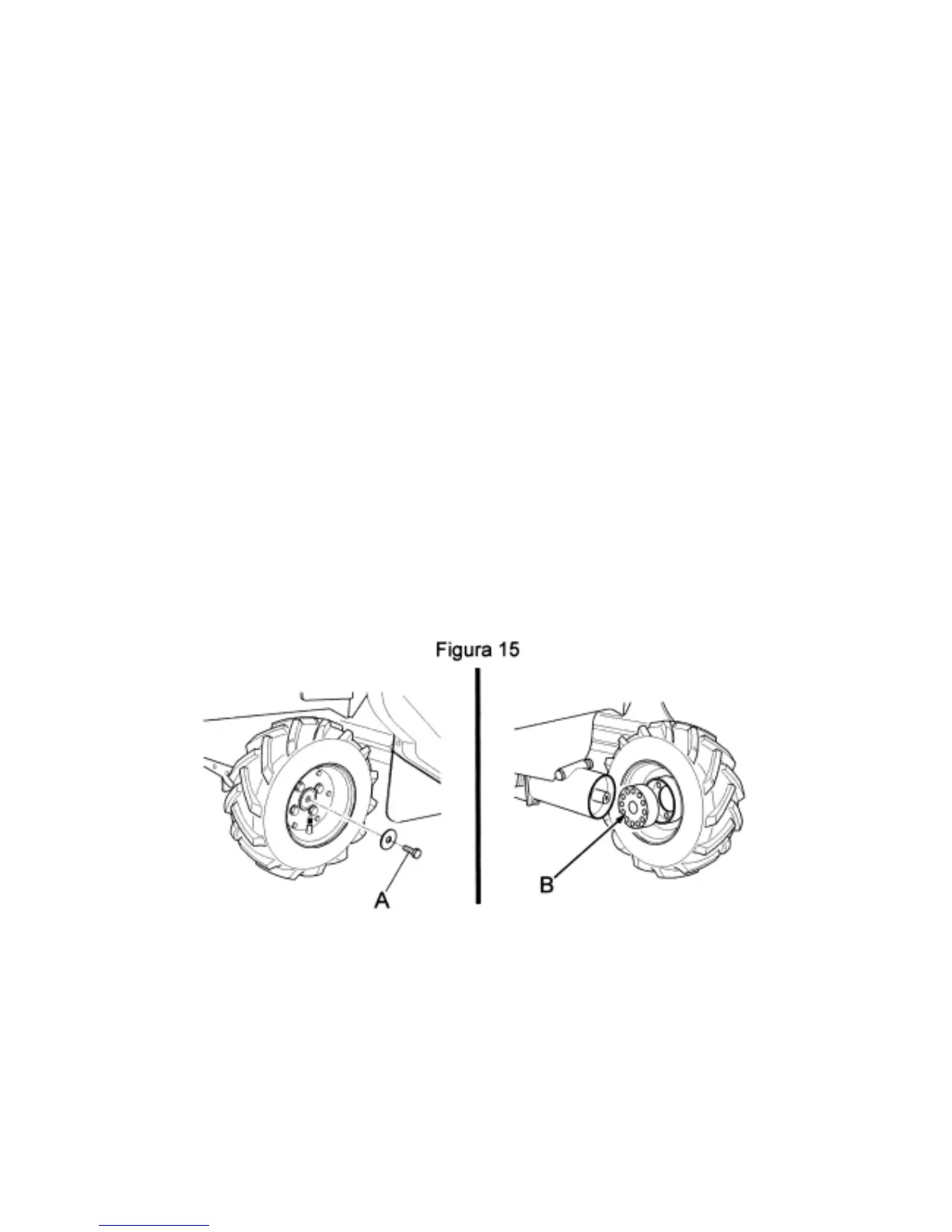

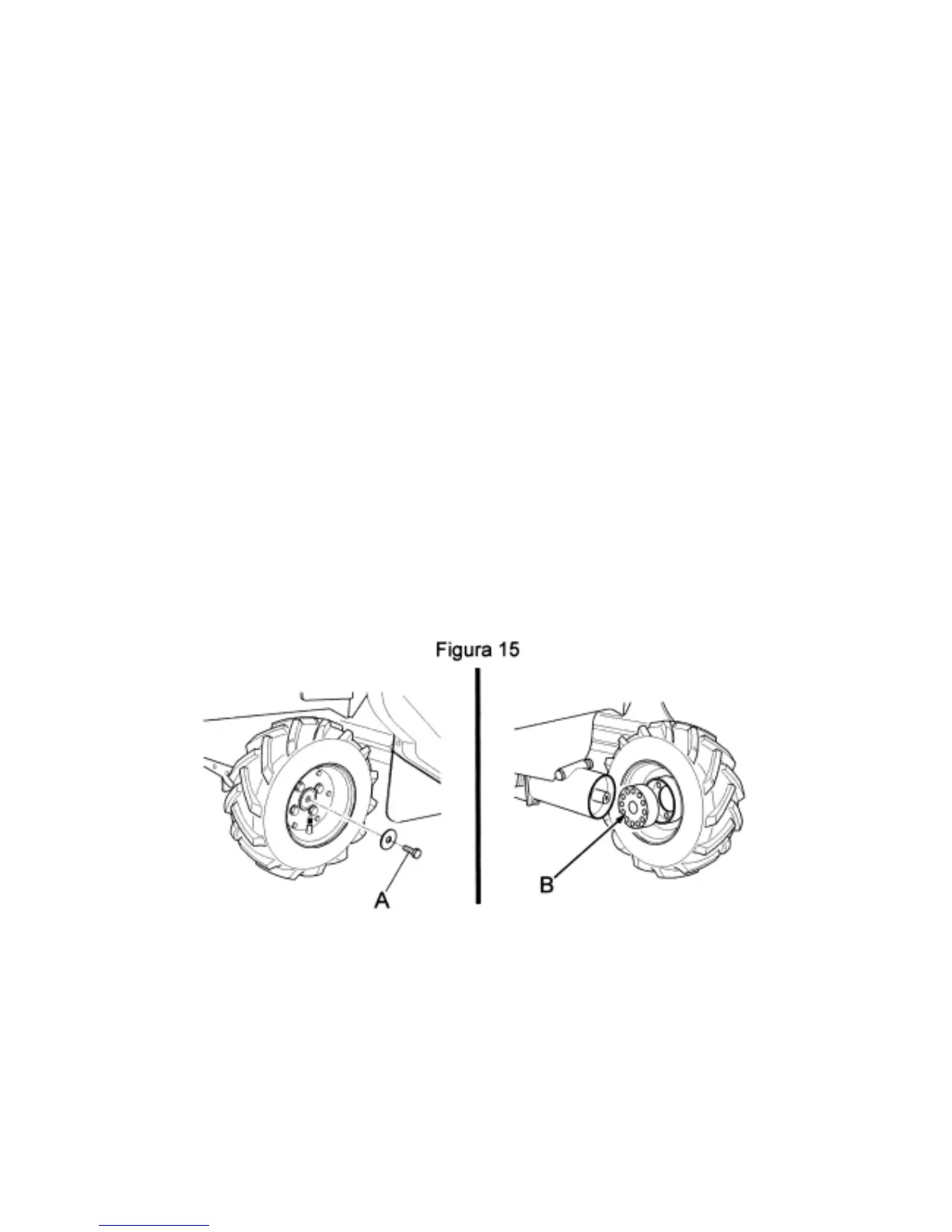

! Every 50 hours grease the wheel release devices, removing the centre screw

shown in fig. 15 (ref. A). Remove the wheel completely from its hub, grease the

exposed part ( fig. 15, ref. B) and then remount the wheel.

Figure 15

Loading...

Loading...