Refuelling and adding oil to the chain lubrication system

ENGLISH 11

6. Refuelling and adding oil to the chain

lubrication system

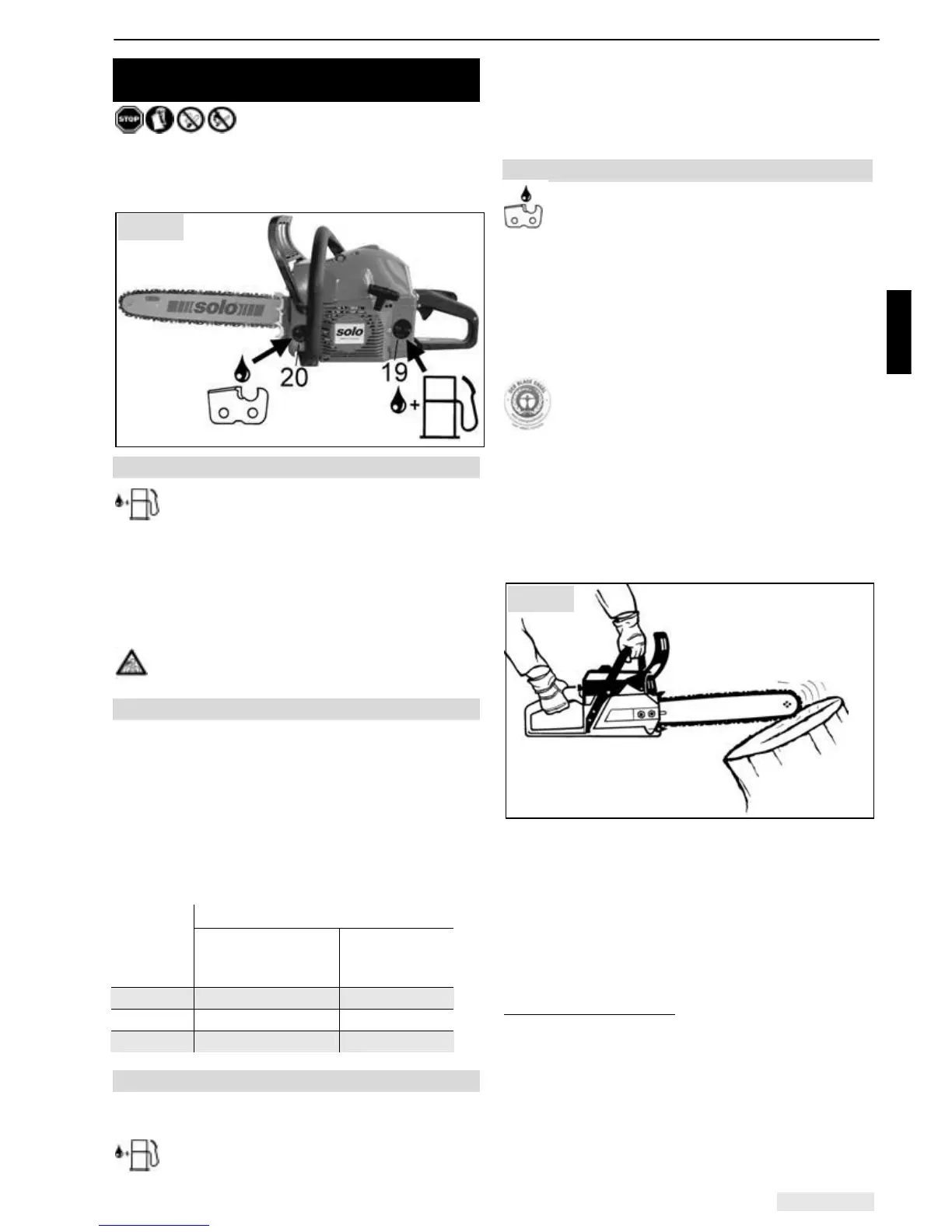

The tank caps for the fuel tank and the chain lubrication

oil tank are sealed by means of an O-ring. Both tank

closures should only be tightened finger-tight, without

the use of tools.

6.1 Fuel information

A high performance two-stroke engine operated

with a petrol:oil mixture (petrol + oil = fuel

mixture) or with a special fuel mixture for two-stroke

engines available from specialists powers this machine.

The fuel mixture can be made up with standard lead-

free petrol or with lead-free premium grade petrol. The

minimum octane rating for petrol is 92 ROZ.

Unsuitable petrol or deviations in the mixing ratio may

lead to serious engine damage!

Avoid direct skin contact with petrol and avoid

inhaling petrol fumes - health hazard!

6.2 Mixing ratio

Always use a fuel:oil ratio of 25:1 (4%) for the first five

tank fillings.

After that we recommend a ratio of 50:1 (2%) with the

use of special two-stroke oil "SOLO 2T engine oil"

which we can supply.

With the use of other brand two-stroke oils we

recommend a ratio of 25:1 (4%).

Never store fuel mixture longer than 3 - 4 weeks.

Fuel mixture table

Oil in litres Petrol in

litres

SOLO 2T engine oil

2% (50 : 1)

Other two-

stroke oils

4% (25 : 1)

1 0,020 0,040

5 0,100 0,200

10 0,200 0,400

6.3 Fuelling

While fuelling always follow all safety instructions and

take all safety precautions.

Handle fuel only with the engine turned off.

Carefully clean the area around the filler inlet.

Place the machine with the fuel inlet pointing upwards.

Unscrew the tank lid and fill the fuel mixture up to the

lower edge of the filler neck. Use a funnel with filter to

prevent tank contamination. After filling the tank replace

the tank lid and tighten firmly.

6.4 Chain lubrication

Chainsaw oil with an anti-fling additive that helps

the oil adhere to the chain should be used for

lubrication of the saw chain and guide bar.

Note: You should generally always add the chain oil

whenever topping up with fuel.

If the saw is used regularly we recommend the use of

biodegradable chainsaw oil.

The bio-chainsaw oil available from SOLO (order no. 00

83 107, 1 litre) has been awarded the German blue

angel symbol for eco friendliness (RAL UZ 48).

Biodegradable chainsaw oil only has a limited

lifespan and should be used within a period of 2

years from the printed date of manufacture.

Important: If you are planning to not use the saw for

more than 2 months and are using bio-chainsaw oil then

you will need to drain the oil tank and then add a small

quantity of engine oil (SAE 30). Then run the chainsaw

for a while to ensure that all bio-oil residue has been

flushed out from the tank, oil pickup hose and cutting

device. Fill up with bio-chainsaw oil again when you are

ready to take the saw back into operation again.

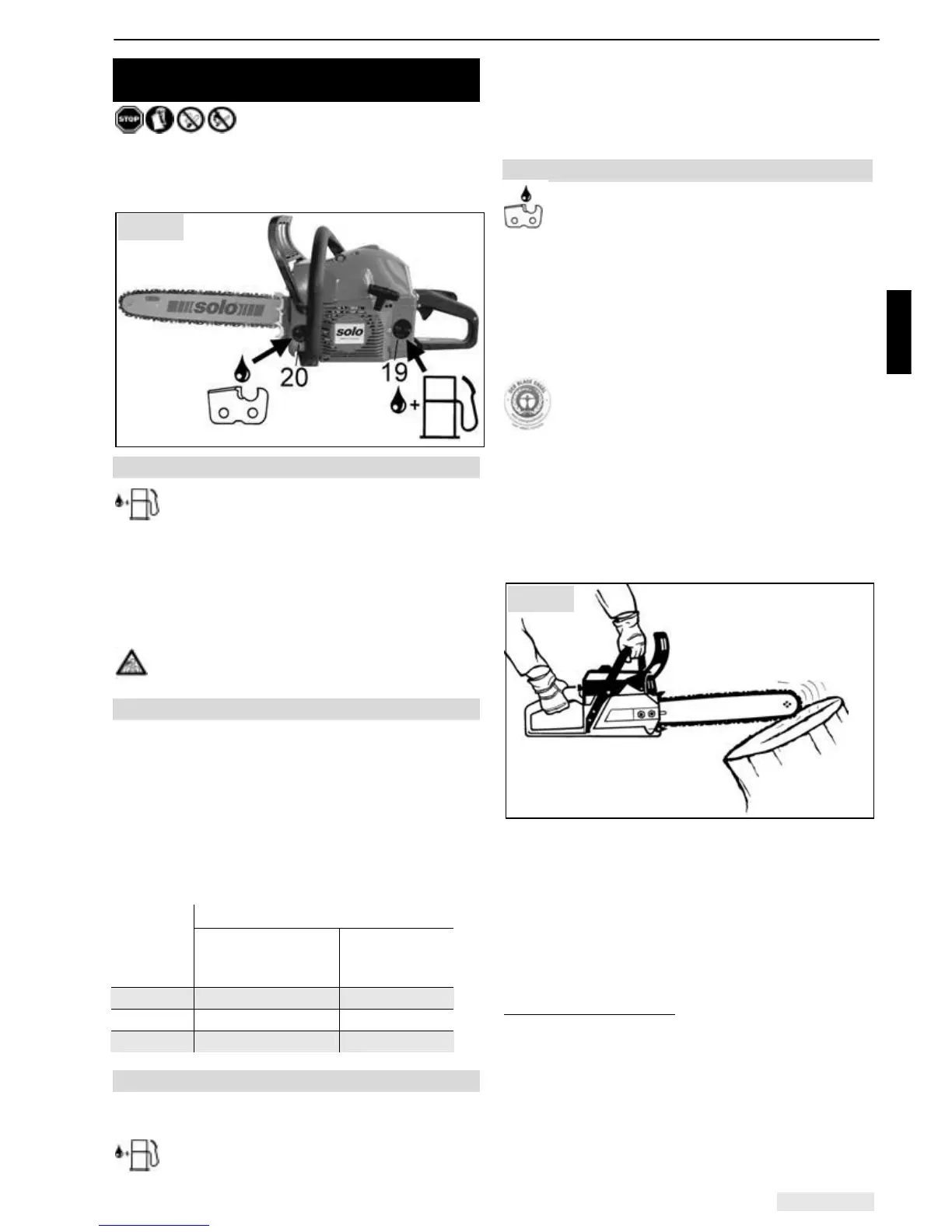

(schematic diagram)

To check the chain lubrication, hold the guide bar above

a lightly coloured object (e.g. a tree stump) and allow

the chainsaw to run in part throttle mode. A light oil trail

should form on the lightly coloured object.

Important: Never work without chain lubrication. Check

the operation of the chain lubrication system and the

level of the oil in the oil tank every time before you start

work. Never re-use old oil.

Notes for new saw chains:

Before installing a new chain

we recommend soaking it in a container (bowl) with

chain oil with anti-fling additives that help the oil adhere

to the chain. Once the chain has been installed, do not

start to cut wood straight away, but allow the machine to

run at part throttle for a while until a slight oil trail forms

on a lightly coloured background.

Fig. 6

Fig. 5

Loading...

Loading...