Operating and maintenance information

ENGLISH 17

11. Operating and maintenance information

With modern equipment and safety-relevant

components, maintenance and repairs must only be

carried out by persons with suitable specialist

qualifications in a workshop equipped with the

necessary special tool and testing equipment. As a

result, the manufacturer recommends that all work

which is not described in these operating instructions

should be performed by a specialist workshop. The

experts have access to the training, experience and

equipment which is required in order to provide you with

the most cost-effective solution. An expert can also

offer invaluable advice.

Always follow all of the safety instructions when

performing maintenance work.

After the device has been run in for around 5 operating

hours, all accessible nuts, bolts and screws (except the

carburettor adjusting screws) should be checked for

tightness and retightened as required.

It is best to store the device in a dry and safe location

with a full fuel tank. There must not be any naked

flames or similar nearby. If you plan to not use the

chainsaw for a longer period (i.e. more than four

weeks), please refer to the information in chapter 11.7

"Taking the chainsaw out of operation and putting it into

storage.

11.1 Maintenance and care of the cutting gear

Saw chain:

Just like any other cutting tool, the saw chain is subject

to natural wear. Your chainsaw will only be able to

deliver its full potential if the saw chain is correctly

sharpened. Every saw chain is matched to the relevant

chainsaw type in terms of its form, cutting performance

and design. Only use the genuine SOLO saw chain

which is approved for your chainsaw / guide bar type.

The key distinguishing factors for the saw chain are:

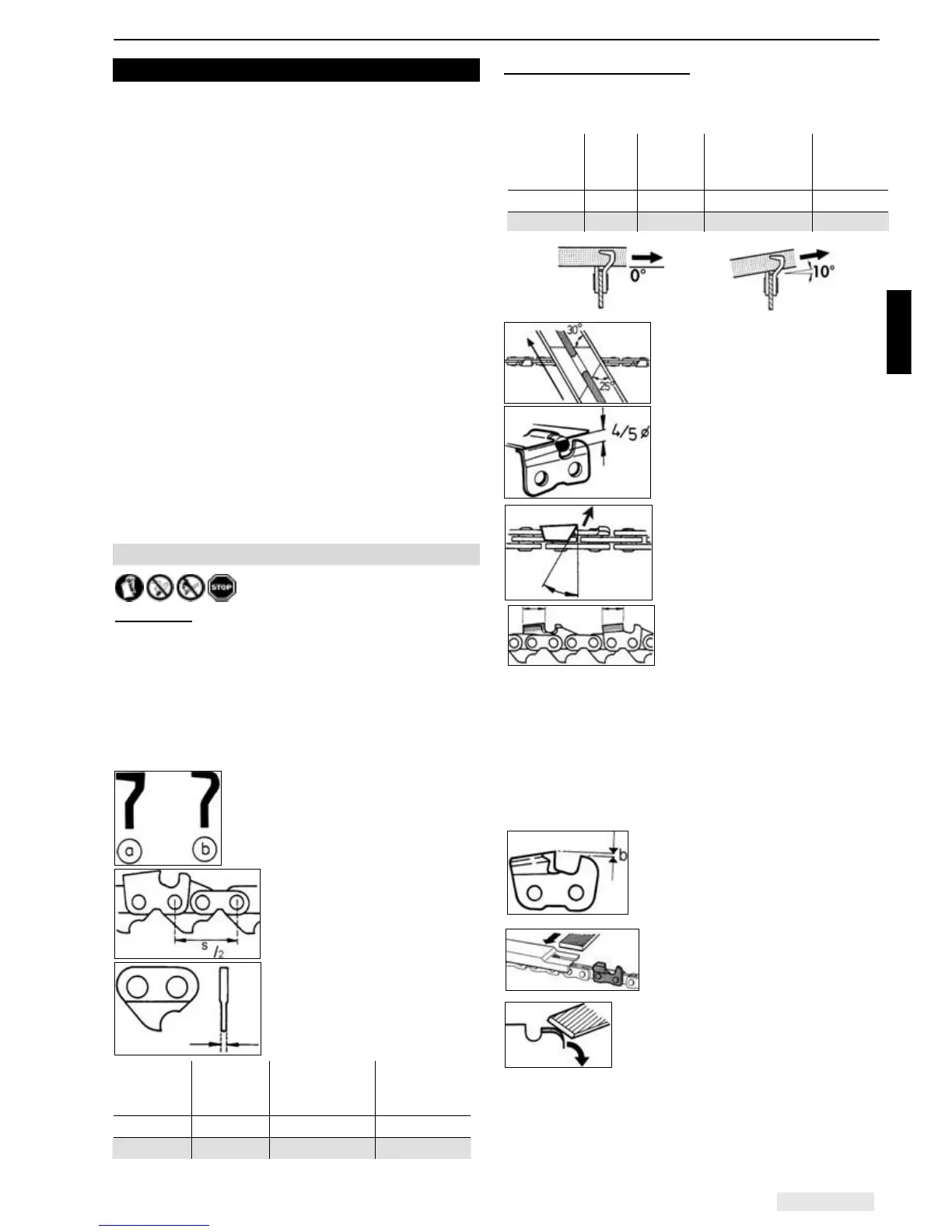

The form of the cutting elements,

a) Solid bit (rectangular cutting tooth,

professional chainsaws)

b) Half bit (half-round cutting tooth,

semi-professional / hobby chainsaws)

The pitch

This is the distance s (from one

rivet to the next but one) divided

by 2.

The pitch is quoted in inches

The driving link thickness

This is the thickness of the part

of the driving link which

protrudes in the guide groove of

the rail.

Pitch

in inches

in mm

Driving link

thickness in

mm

in inches

3/8’’ Spez. 9,32 mm 1,3 mm .050’’

.325’’ 8,25 mm 1,5 mm .058’’

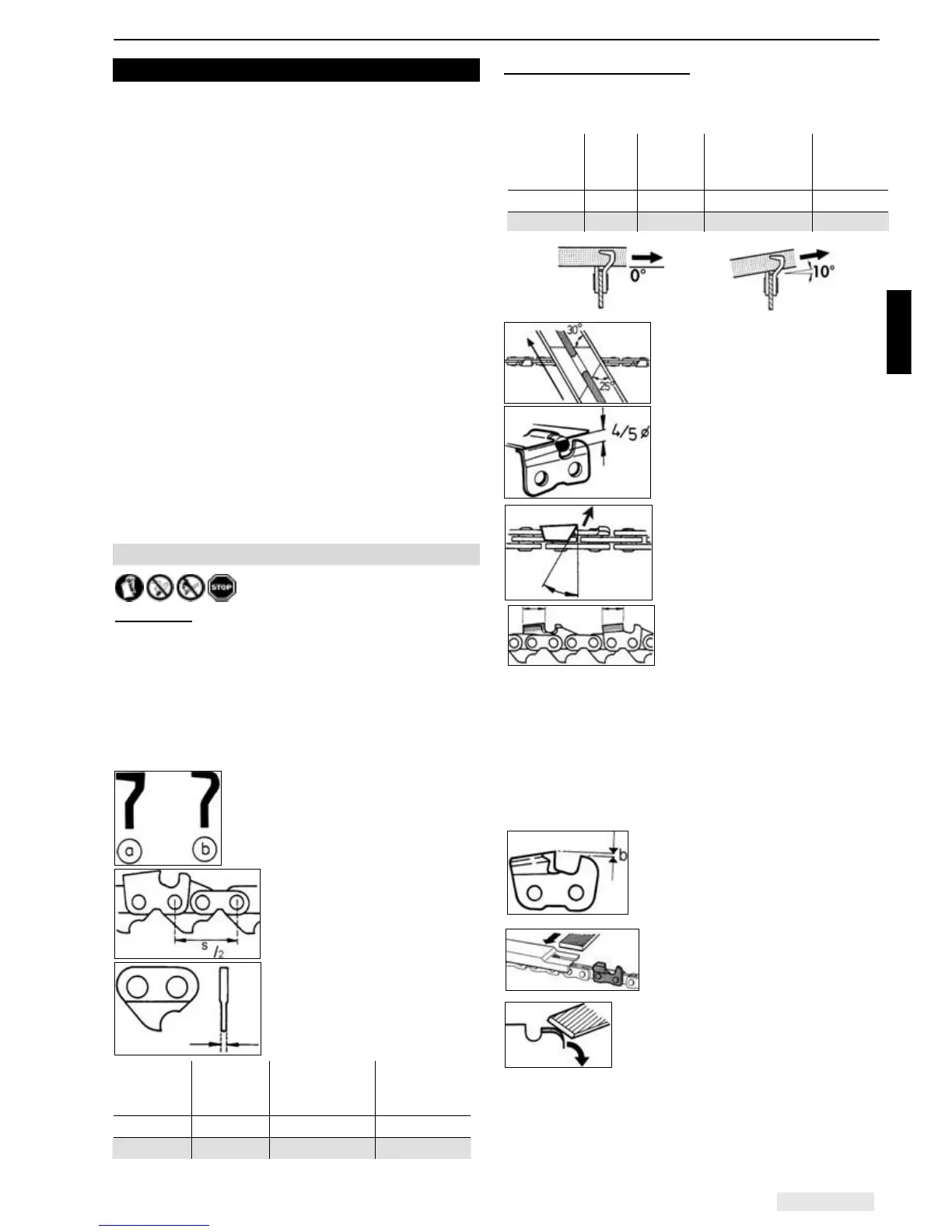

Sharpening the saw chain:

A special round chain file with the correct diameter

should be used for sharpening. Normal round files are

not suitable.

Pitch

in inches

Files Ø

mm/zoll

Filing

angle α

Depth limiter

spacing b

mm/zoll

Filing

direction

3/8’’ Spez.

4,0/

5

/

32

30° 0,64 / .025 0° horizon

.325’’(21BP) 4,8/

3

/

16

30° 0,64 / .025 10° upw.

A file holder makes guidance of

the file easier, as it has

markings for the correct

sharpening angle (align the

markings parallel to the saw

chain) and limits the penetration

depth (4/5 of the file diameter)

Position the file holder on the

roof of the tooth. The file should

only engage during the forward

stroke. Lift the file off when

moving it back.

The shortest cutting tooth is

sharpened first. The length of

this tooth is then the target size

for all the other teeth on the

saw chain. All of the cutting elements must have the

same length.

To start with, file all of the cutting elements on one side

from the inside outwards, then file all of the cutting

elements on the other side.

Always fully file out any damage from the side plate or

the roof of the tooth.

Correction of the depth limiter:

The distance b between the depth limiter (round nose)

and the cutting edge defines the

thickness of the chips. The best

cutting results are obtained with the

prescribed depth limiter spacing,

which should be checked every

time the saw chain is sharpened.

Lay the depth limiter gauge on the

cutting element. If the depth

limiter protrudes, file off the

protruding part with a flat file.

Round off the front edge of the depth

limiter. The original shape must be

restored. CAUTION: If the spacing is

too large then there is a greater risk of

kickback.

For your safety: If you would like to pull the chain

through while filing, pull the chain forwards with a

screwdriver towards the tip of the rail. This will reduce

the risk of slipping.

Loading...

Loading...