2

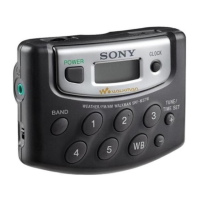

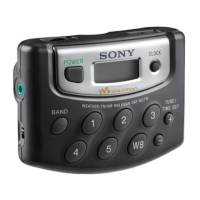

SRF-M97

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 4

2-2. MAIN Board, Cabinet (Front) Assy ................................ 4

2-3. Side Panel Section, Cabinet (Rear) Assy......................... 5

2-4. AMP Board...................................................................... 5

3. ELECTRICAL ADJUSTMENTS ......................... 6

4. DIAGRAMS ................................................................. 8

4-1. Schematic Diagram ......................................................... 9

4-2. Printed Wiring Board – MAIN Board – .......................... 10

4-3. Printed Wiring Board – AMP Board – ............................ 11

5. EXPLODED VIEWS

5-1. Cabinet (Front) Section ................................................... 14

5-2. Cabinet (Rear) Section .................................................... 15

6. ELECTRICAL PARTS LIST................................ 16

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Loading...

Loading...