72

MAITENANCE E CLEANING

BSS-134

CHAP.- 10

10.7.2 Extraordinary maintenance

Chain transmission

A chain transmission is used to transmit the movement between the two shafts of the same machine,

as well as between an electric motor, or any other source of power, and an independent mechanism.

The chains are subject to extensions, wear and corrosion.

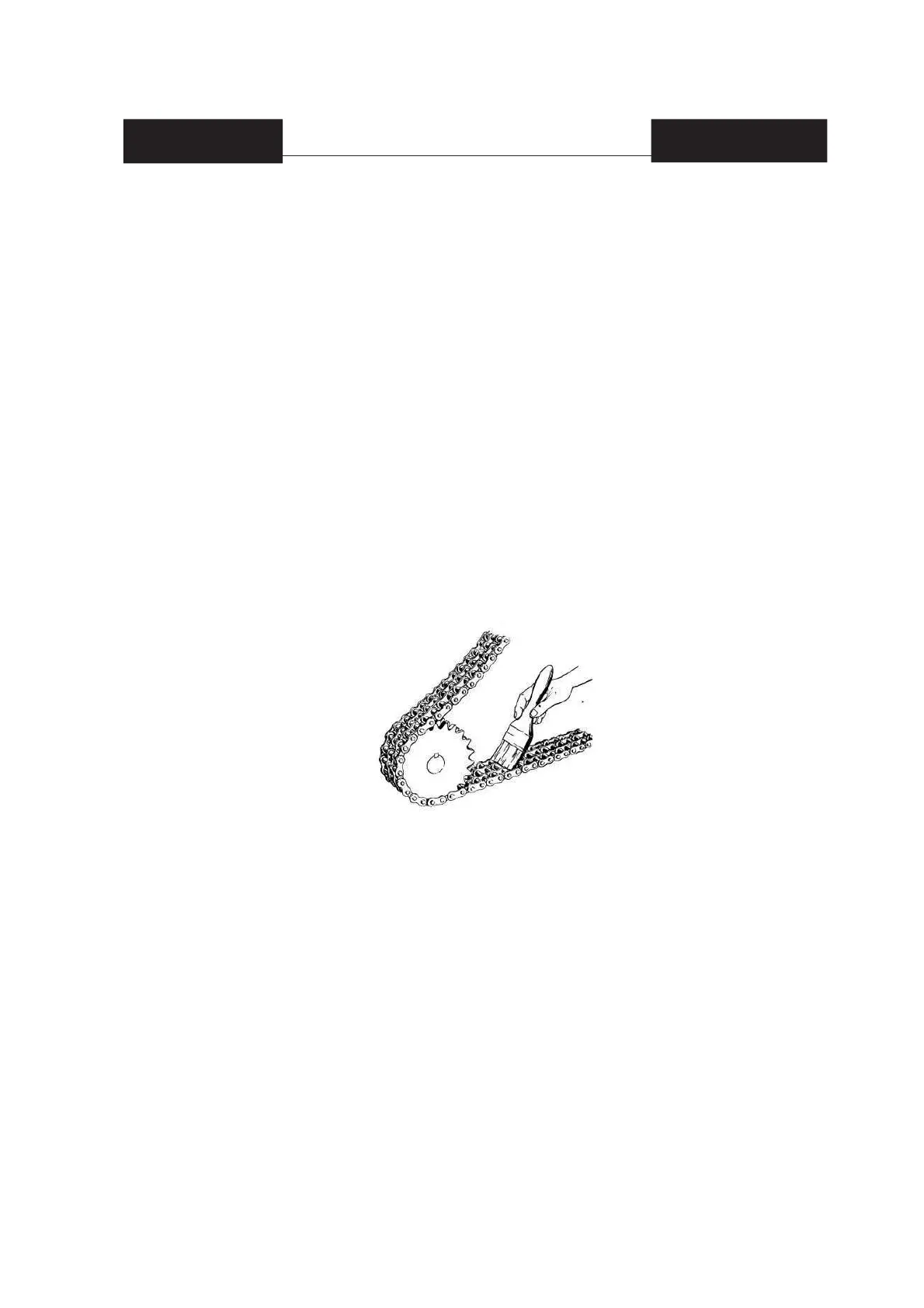

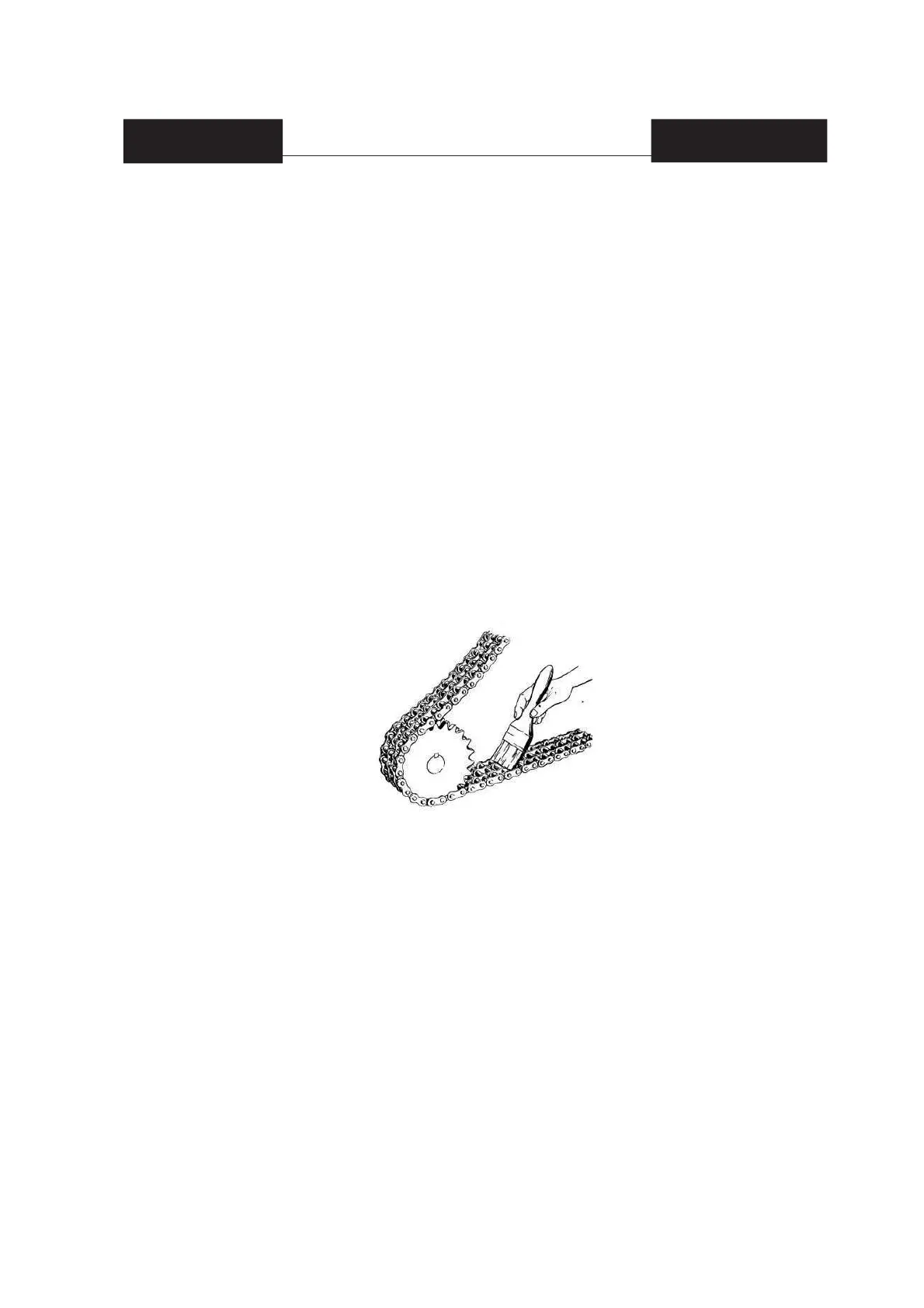

Lubrication

An appropriate lubrication is important to guarantee long duration of a chain transmission.

In fact, during working, the pins, the bushes, the rollers, the internal and external sides of the plates,

the teeth sides of the pinions, rotate one in relation to the other and would be destroyed if the surfaces

were not protected by a fi lm of lubricant.

Lubrication protects the chain from oxidation and from corrosion, contributing in decreasing the noise

of the same transmission.

The lubricant must be periodically applied with a brush or with a manual lubricator and must be applied

inside the chain’s ring and, preferably, on the edges of the plates.

It is necessary to adjust the frequency of the applications and the amount of lubricant so as to have

complete lubrication, but without squirts and drippings.

Usually, an application of oil every working week is suffi cient in most cases.

Chain Transmission Assembly

An accurate assembly of a chain transmission allows obtaining a long period of service from the same.

Fastening of the shafts

Any misalignments due to premature subsidence of the supports signifi cantly reduce the useful life-

span of the chain and can often cause its breaking.

Alignment of the shafts

Check that the shafts are correctly aligned and parallel.

Alignment of the pinions

Verify the axial alignment of the toothed wheels by means of a ruler; the ruler must rest against the

worked side of the pinions. Should the wheel base be signifi cant, such not to allow the use of the

ruler, use a fl exible thread, assuring that during the operation, the same is well tensioned.

Should, for one of the shafts be envisioned a axial clearance, it is best to temporarily fi x the shaft in

its normal working position and proceed with the alignment of the pinions.

Loading...

Loading...