21

INSTALLATION

BSS-134

CHAP.- 6

6.1 Putting at work

The machine must be positioned inside a work place that protects it from bad weather and climatic

differences of the weather, without circulation of dust and without excessive temperature changes in

order to avoid damaging condensation of residue humidity. The range difference must be between

+5°C and +40°C.

Environmental conditions different from those specifi ed can cause serious damages to the machine

and, in particular, to the electronic equipment, therefore for different environmental conditions, the client

must inform Sorma S.p.A. to evaluate the possibility of applying adequate systems to the machine to

guarantee the good functioning.

The positioning of the machine in environments not corresponding to that indicated, expires the

warranty for the parts to be replaced.

The various parts of the machine must be positioned carefully in the place decided on beforehand.

The machine has been designed to reduce noise at its source.

There are no noise reduction devices, as the values measured near the machine are below the limit

values foreseen by law.

There is a risk condition if the machine is inserted in a reverberating environment or in the presence

of other sources of noise and the daily personal exposure level exceeds 80 dB(A); in this case the

employer must provide the worker with personal protective equipment (ear muffs, earplugs).

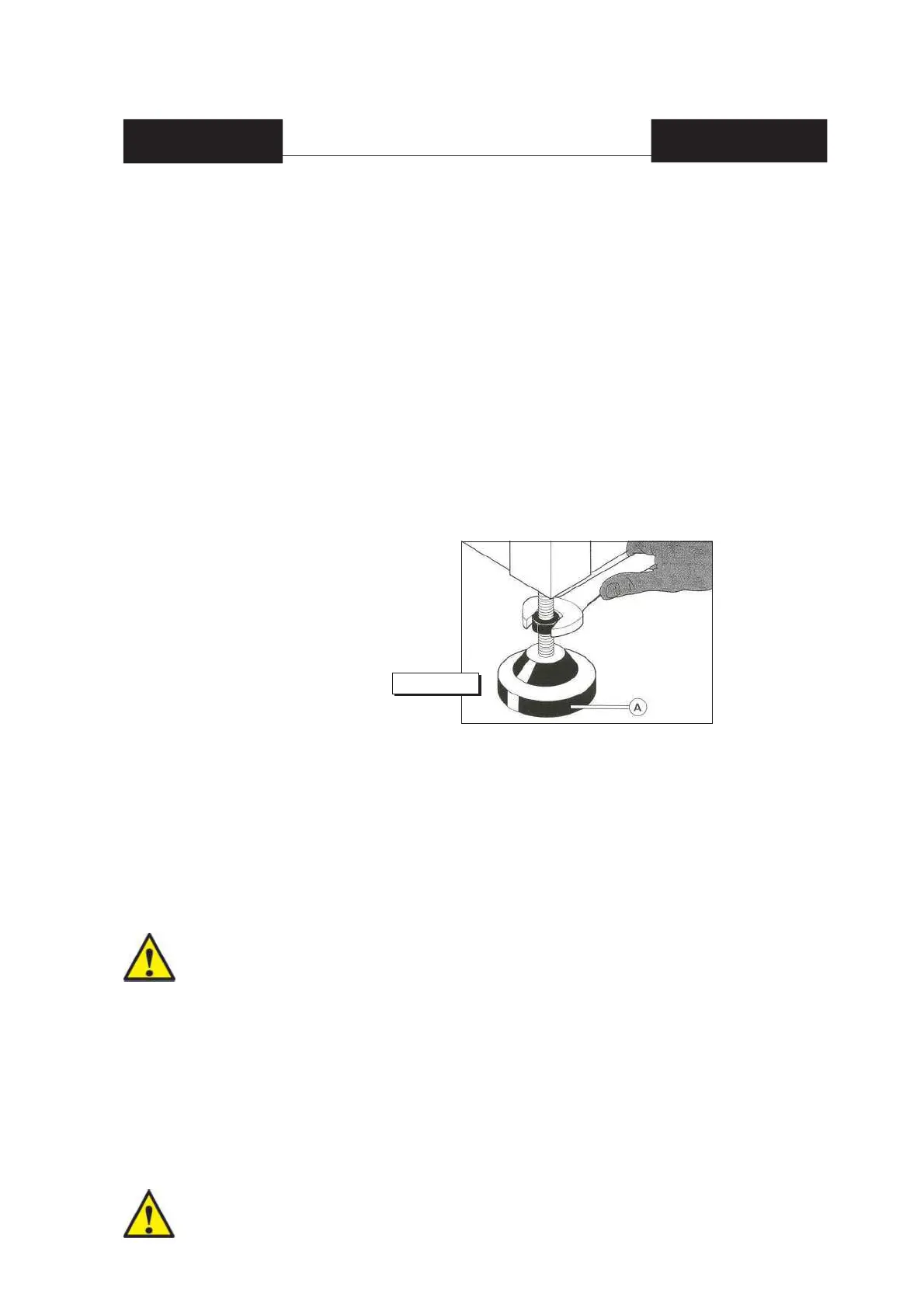

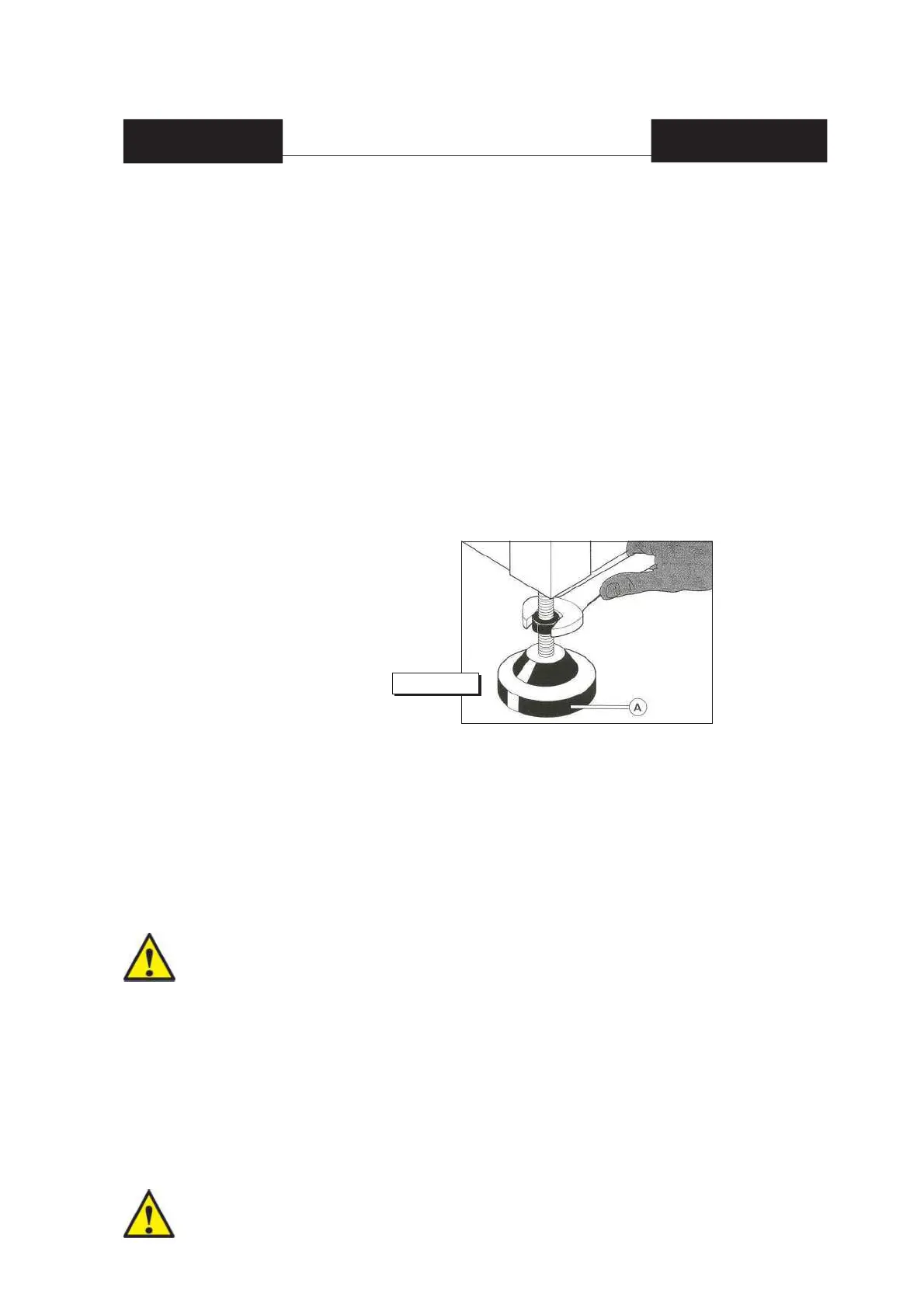

The machine must be placed on a fl at fl oor. Any small level differences must be taken care of by

adjusting height of the feet (see fi g.1 chap.6).

Fig.1 chap.6

6.2 Space necessary for the operator

The space necessary for the operator for the correct use of the machine and those in charge of

maintenance, must be of at least 80/100 cm.

This space must be left along the entire perimeter of the machine. Also consider that, in case the

physical characteristics and/or need of moving to perform the above quoted operations correctly and

safely, or if the operators should request it, such space must be brought to a value higher than that

indicated above.

6.3 Wiring conections

The activities described in this paragraph must be carried out only by qualifi ed staff, and

precisely:

- TECHNICIAN trained through specialisation and training courses and with experience

with regard to installation, start-up and maintenance of the systems, and is aware of the

accident-prevention Standards.

Make sure the mains voltage and frequency are the same as the data shown on the power cabinet.

The power cabinet must be connected to power source provided with a suitable magnetic tempera-

ture cut-off switch. Machine power connections and preliminary testing must be performed by expert

technical personnel which must make sure that the power supply voltage of the machine is the same

as the local mains voltage, and must perform all connections safely, according to current law. For

power connection, use a four-pole cable with a minimum cross-section of 2.5 mmq and connect it to

the terminals R S T and to the neuter N (see fi g.2 chap.6).

(every time check the minimum section according to the distance).

The machine must be connected to the power mains only by specialised personnel

and the machine must be protected by a HIGH SENSITIVITY ground fault circuit

interrupter according to rules for good practice and safety.

Loading...

Loading...