•

Be sure knives are sharpen uniformly. If necessary substitution, replace with original

knives.

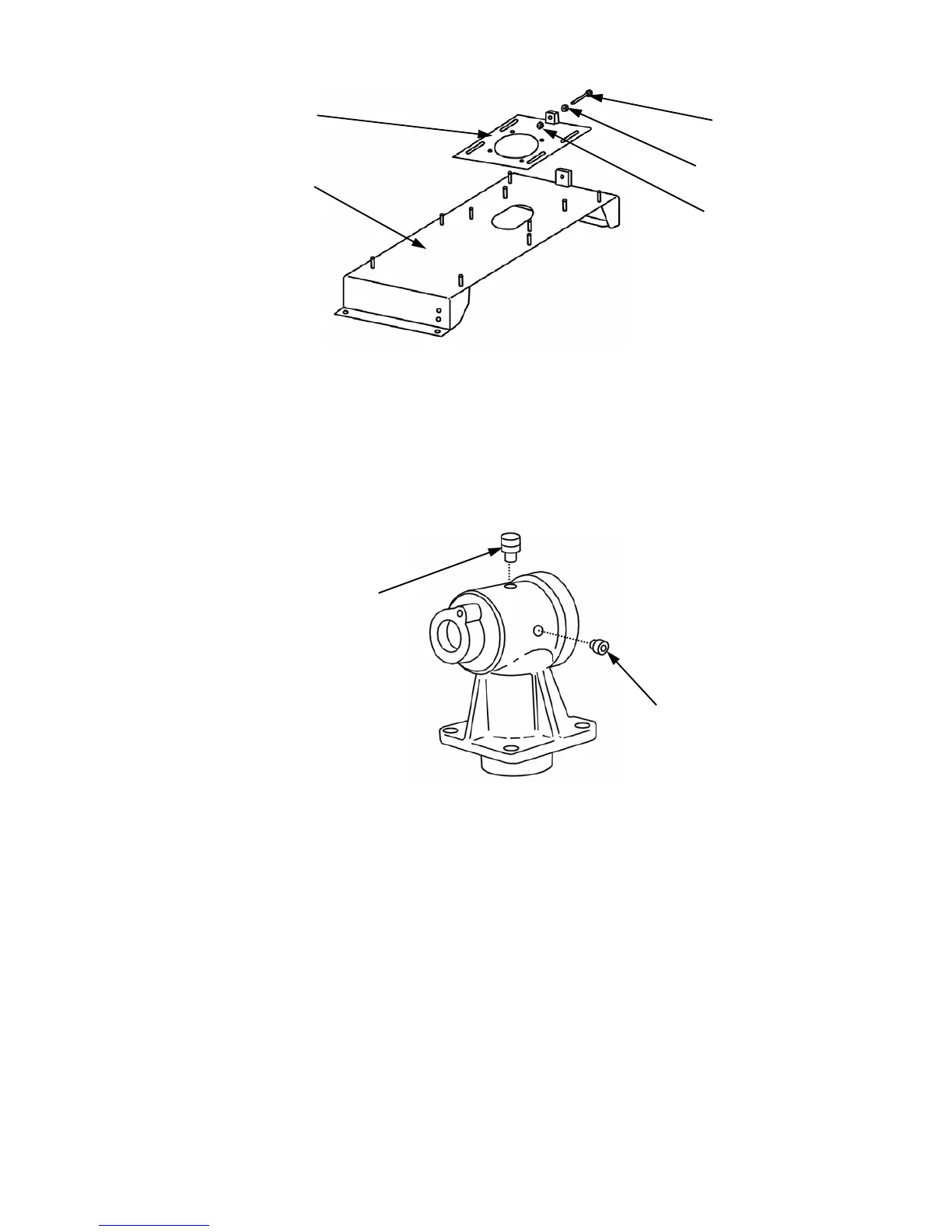

• Check gearbox correct oil level. To proceed, remove the oil level screw (see fig. 4). If

needed to add oil, remove the filler screw located on top of the box, and fill in until oil

starts running out of the level hole.

Every 50 working hours

•

For those versions of the machine equipped with rear roller, proceed to grease its lateral

supports. Before greasing, clean the grease nipple correctly for better lubrication. Use lith-

ium type grease NLGI2.

First 100 working hours

•

When the machine has done its first 100 hours, change the oil from the gearbox. To pro-

ceed, drain all the oil through the level screw hole after leaning opportunely the machine,

then fill in with new oil through the filler hole. This substitution is necessary because the

gears are new and so are subject to quicker worn. Use oil SAE 80 W 90 API GL4.

Pag.26

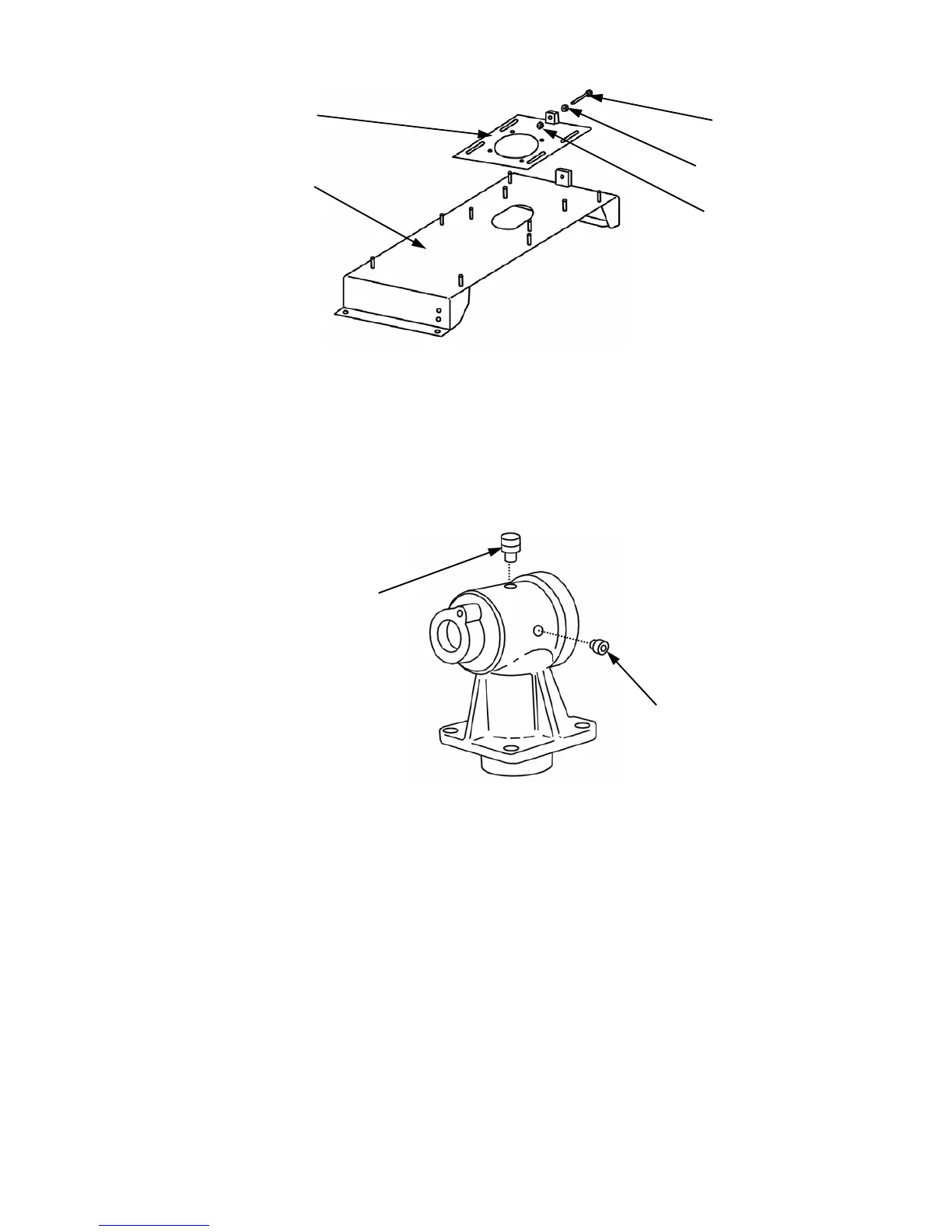

CASE

SUPPORT

TENSIONING

SCREW

COUNTER NUT

BLOCKING

NUT

FIG. 3

FILLER

SCREW

LEVEL SCREW

FIG. 4

Loading...

Loading...