– 22 –

Model LAHP48 Air to Water Heat Pump — Installation, Operation & Maintenance Manual

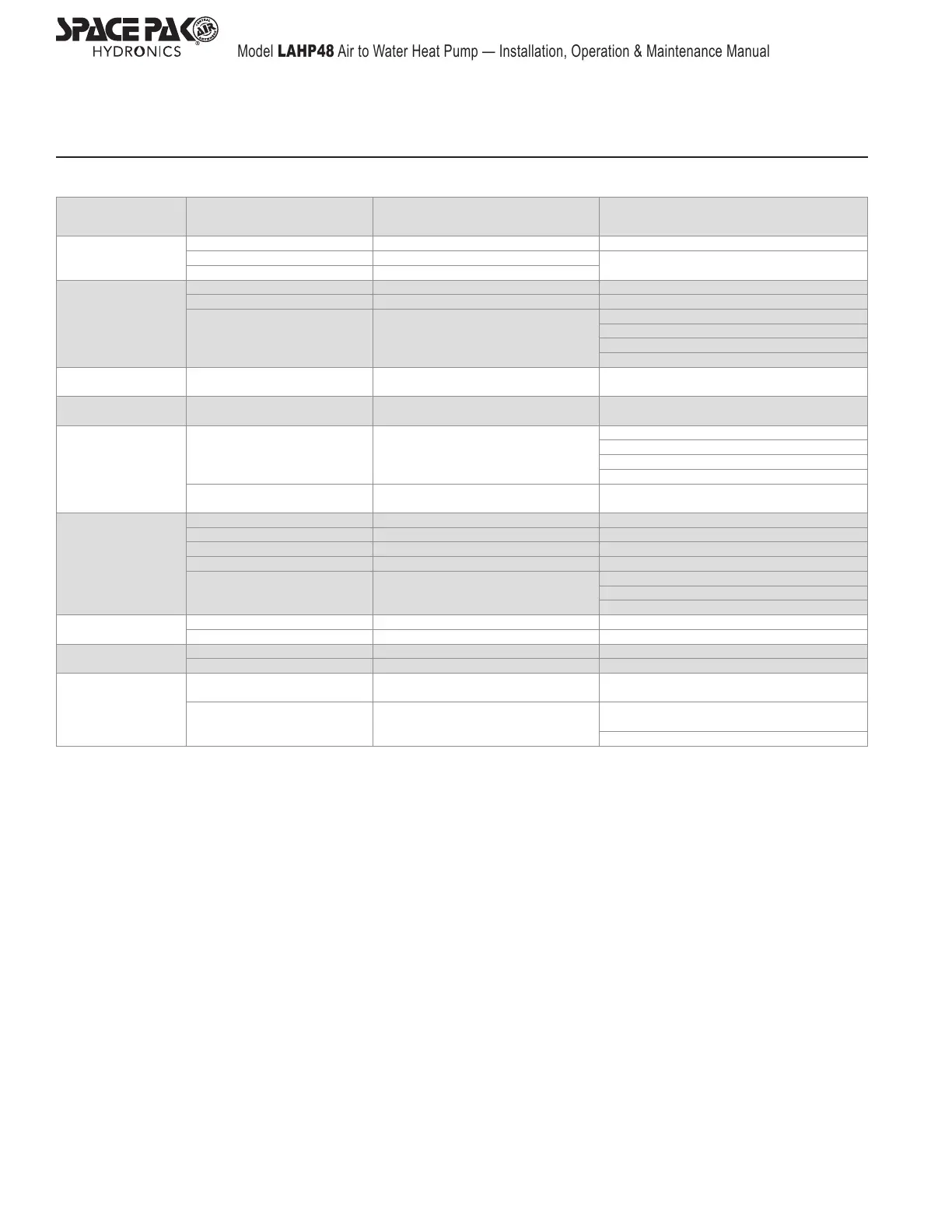

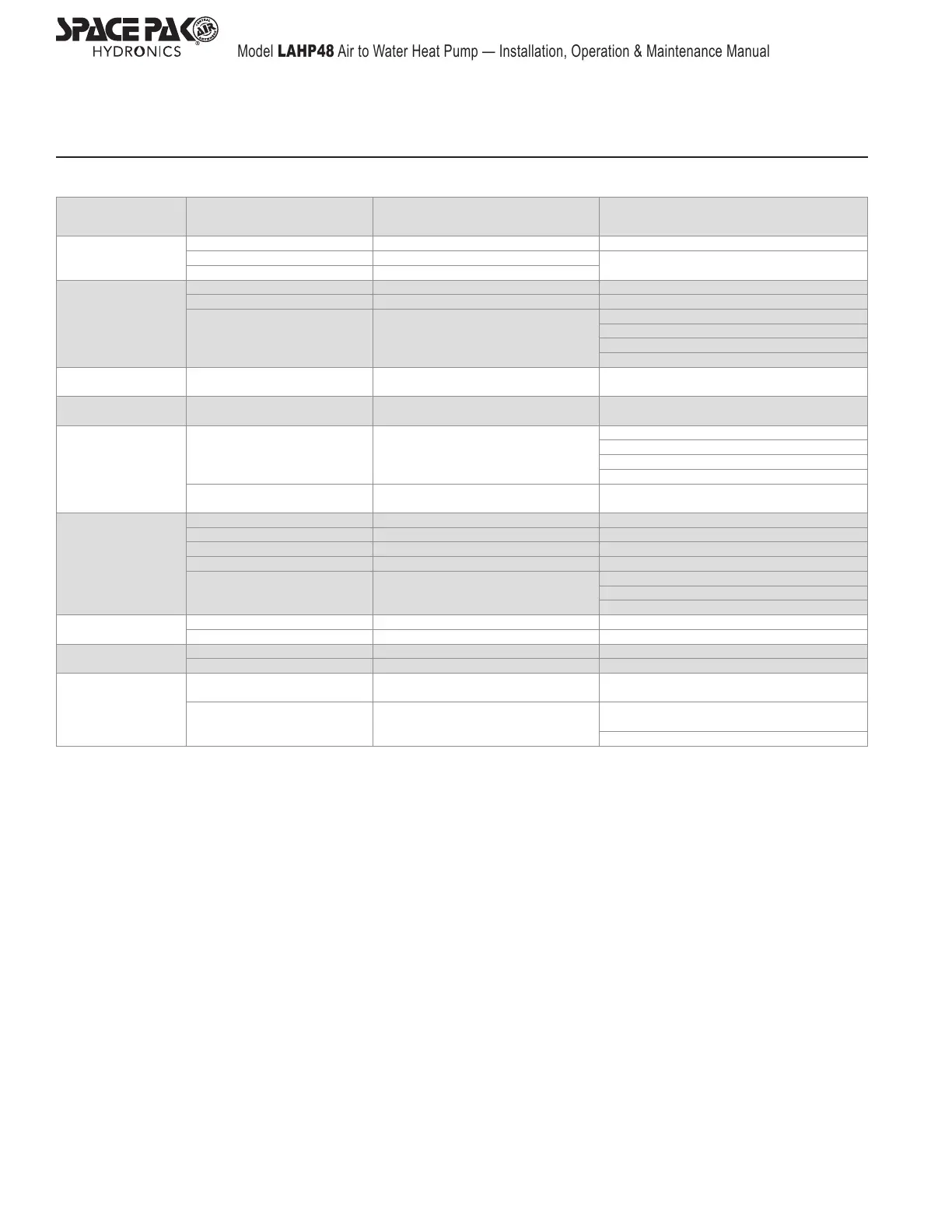

Section 10: Troubleshooting

Condition Possible Causes Verification Solution

Unit will not start

Incorrect power supply Check power supply Supply correct power, 220-240 60Hz

Loose or broken wires Check wiring

Repair or replace wiring

Circuit breaker interrupted Check for short

Compressor running -

insufcient cooling/heating

Insufcient pipe insulation Check insulation Add/repair insulation

Dirty coil Check coil Clean coil

Low water ow Look for alarm symbol and FL fault code

Clean strainer screen

Clear blockage

Remove air in piping

Verify operation/condition of water pump

High compressor discharge

pressure in cooling

Dirty coil Check coil Clean Coil

High compressor discharge

pressure in heating

Low water ow Measure water ow through heat exchanger Flow should be a minimum of 10 GPM

Low compressor suction

pressure in cooling

Insufcient / no water ow Look for alarm symbol and FL fault code

Clean strainer screen

Clear blockage

Remove air in piping

Verify operation/condition of water pump

Cooling operation in low Ambient

Conrm outdoor ambient is lower than typical for

cooling operation, i.e. <55°F

If low ambient cooling is desired, contact Technical Support

for procedure to modify fan operating parameters.

Compressor will not run

Power supply failure Supply correct power, 220-240 60Hz

Failed compressor contactor Replace contactor

Loose power cable Check power cable Tighten power cable

Incorrect return water temperature setting Check return water temperature setting Adjust return water temperature setting

Low glycol/water ow Look for alarm symbol and FL fault code

Clean strainer screen

Clear blockage

Remove air in piping

Fan will not run

Fan controller failure Replace fan controller

Fan motor failure Replace fan motor

Compressor runs - no

heating/cooling

No refrigerant charge Check for leaks Add appropriate refrigerant

Damaged heat exchange Check for glycol/water leaks and/or refrigerant leaks Replace heat exchanger

Low outlet glycol/water

temperature in cooling

Improper temperature control setting Check cooling temperature setpoint and differential

Contact Technical Support for instructions to reset cooling

setpoints

No load/rapid temperature drop

Ensure compressors are allowed to run a

minimum of three minutes before reaching desired

temperature

Verify cooling function when there is sufcient heat load to

allow continuous operation.

Ensure system volume is at least 40 Gallons

Figure 20 Troubleshooting Suggestions

Loading...

Loading...