8

5.3 „Büffel“ Pump

Single ‘’Büffel’’ piston pumps are screwed on to a brick or concrete base and secured with foundation bolts. No

particular foundation is required for vertical tanks. Pumps without a base plate and therefore without vibration

insulation should be mounted on to a piece of anti-vibration material placed between the pump and ground.

5.4 Suction Line for Pump Units and ‘’Büffel’’ Pumps

Perfect functioning of the pump depends largely on well layed-out suction lines. In order to prevent air-

pockets, the suction line should rise gradually from the well to the pump, or should at least be layed

horizontally. It must be absolutely seal proof and the inner diameter should at least be as large as the

connection on the pump. Only bows are to be used, no elbows.

It is advisable to install a foot valve or an intermediate valve in the case of a closed filter well. If suction

lines are longer than 30 m, a suction air chamber is to be installed directly in front of the pump. If vertical

tanks are used (fig. 113), it is advisable to support heavy suction lines so that their weight does not pull

on the pump.

5.5 Suction Head

The total gauged suction head which is the height between the water level and the pump plus loss of

friction in the pipe and possible filter resistance, is not to exceed 7.5 m, not forgetting that in dry seasons

the water level in the well may be lower than usual.

In the case of short suction lines or a suction head of below 2m, or if input pressure is present, a shut-off

valve (not a tilted seat-valve) must be installed in front of the pump. This shut-off valve can be adjusted

with greater accuracy to the required suction head, ensuring the avoidance of water-hammer.

5.6 Intake Pressure - Pump Unit as Booster Set

If the inlet pressure is more than 0.3 bar (3 m), it is advisable to install a pressure-free tank with float

valve. If this cannot be done, a shut-off regulator valve must under all circumstances be installed in the

feed line. A vacuum of 4-6 m has to be provided if the automatic air volume control is to function properly.

If the pump hammers, install a suction air chamber (approx. 7.5-15 ltrs) in the feed line. A shut-off valve is

at all events necessary in a suction line with intake pressure so the pump can be opened for servicing.

5.7 Discharge Line - Refers only to installation of pump units with vertical tanks or pumps alone

If possible, the line should rise gradually upwards from the pump to the tank or at least be horizontal - it

should never slope downwards. Only use curved joints, elbows may only be used after the tank.

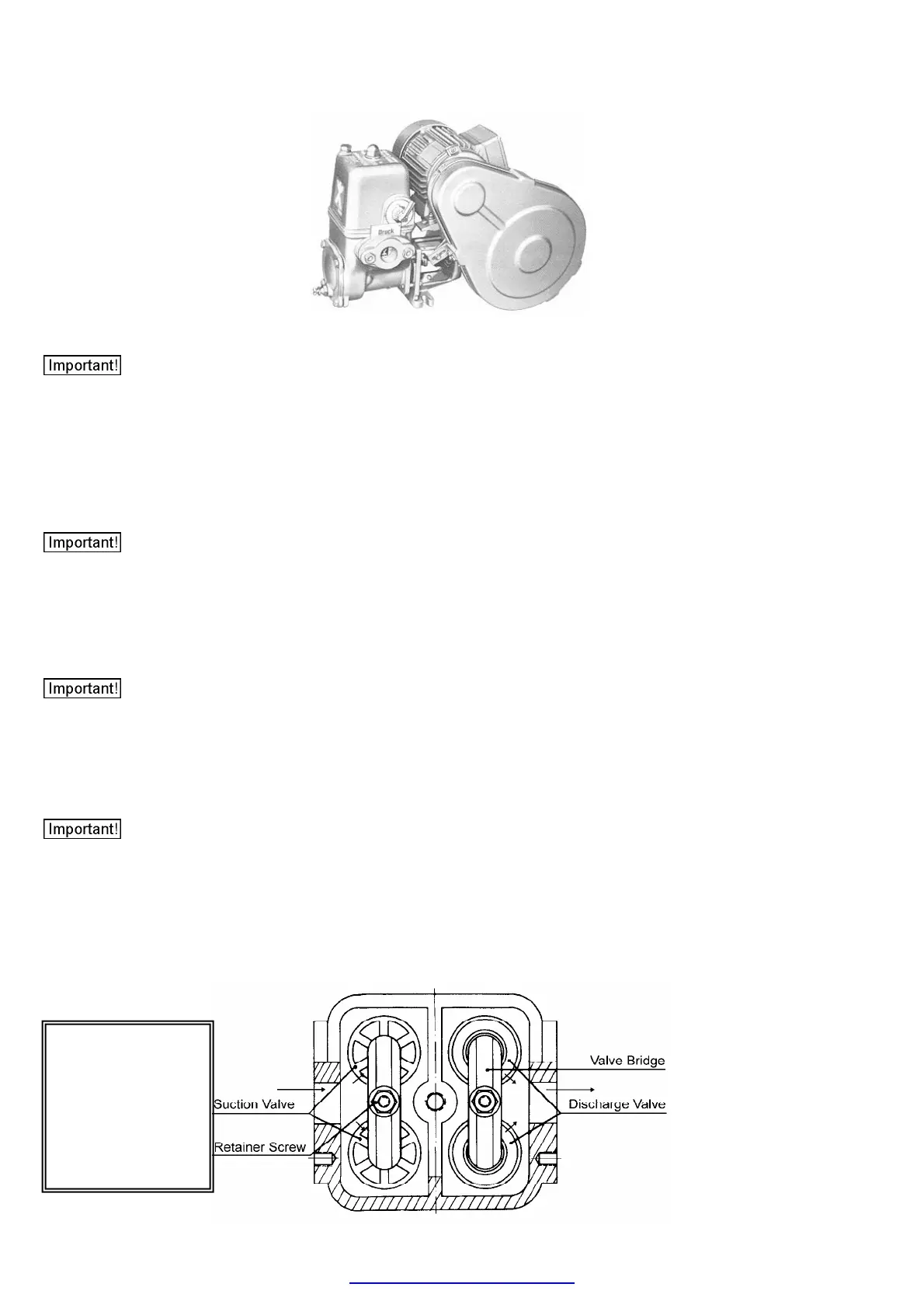

5.8 Umtausch der Saug- und Druckanschlüsse

(Does not apply to units with horizontal tanks)

The suction and discharge sides of SPECK ‘’Büffel’’ pumps can be interchanged by converting the suction and

discharge valves. This often saves inconvenient installation of suction and discharge lines. Install clean valve seals

and make sure the valves sit properly.

Fig. 112 „Büffel“ pump

After suction and discharge

valves have been exchnged, the

air chamber must be turned

around 180° so that the safety

valve is always located on the

dischar

e side.

see fi

ure 115

Fi

. 114

Starting torque of

holding screw:

BS15: 12Nm (M8)

BS25: 16Nm (M10)

BS40: 18Nm (M10)

BS50: 36Nm (M12)

Loading...

Loading...