27

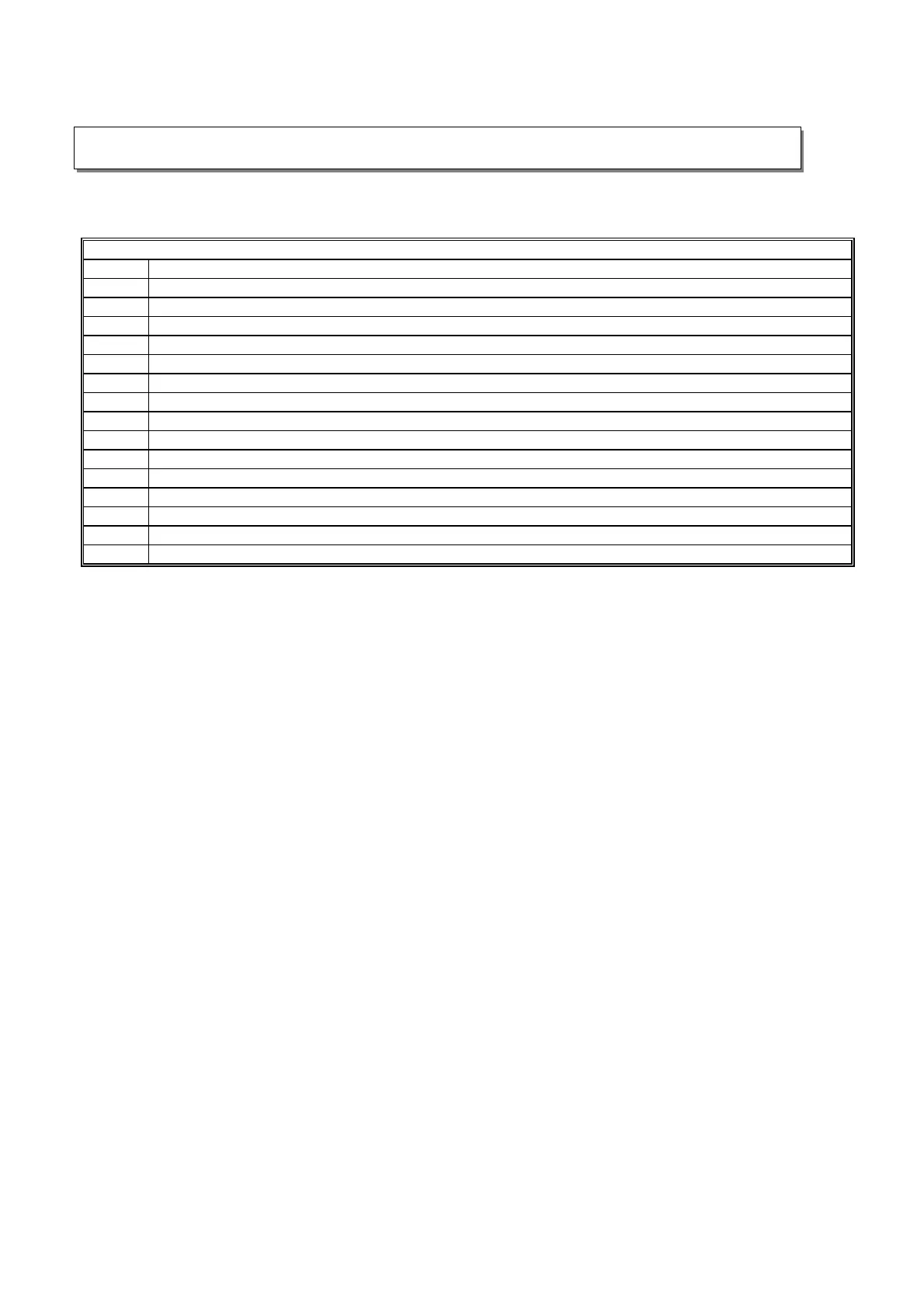

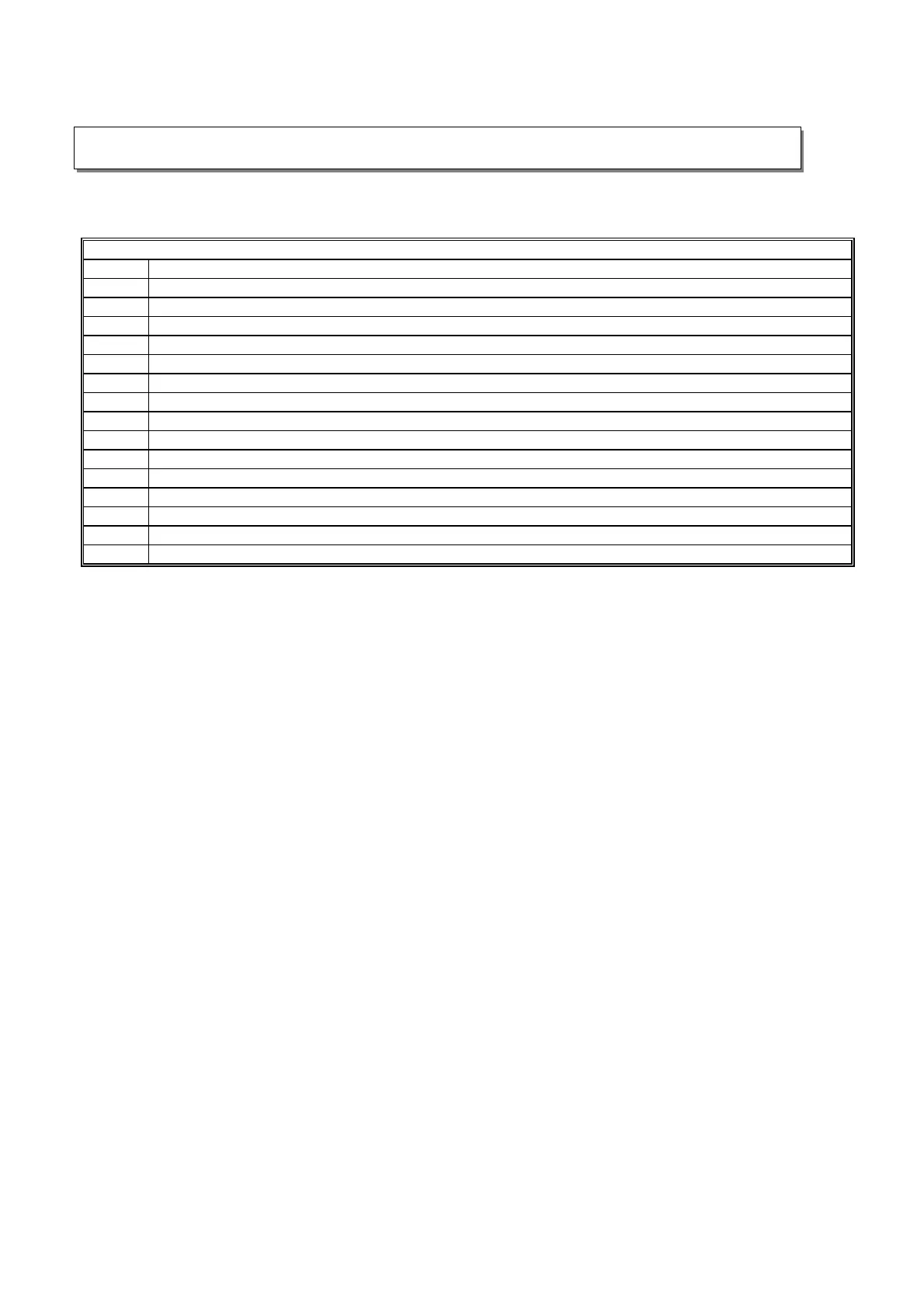

4.0 LEGEND

A 5,5 COLOURED DISPLAY

B ENCODER (OR JOYSTICK) FOR PROGRAM SELECTION

C AIR TEMPERATURE SENSOR

D KEYBOARD WITH 9 KEYS

E HIGH PRESSURE COUPLING

F LOW PRESSURE COUPLING

G USED OIL PLASTIC BOTTLE

Ha NEW OIL PLASTIC BOTTLE

Hb TRACER PLASTIC BOTTLE

I BOTTLE SECURITY VALVE

L USB SERIAL PORT

M POLISNAP MODULE

N DRAWER FOR ACCESSORIES

O VACUUM PUMP WARNING LIGHT

P PRINTER

Q INCONDENSABLE GASES DISCHARGE OUTLET

4.1 MESSAGES ON THE DISPLAY

All signals will be displayed on the LCD.

When switching on the machine the display shows the amount of freon, which is available inside the internal

bottle.

If an error occurs during the execution of the phases, the display will show an Error message.

The Errors are the following:

When a minimal amount of freon is available inside the internal bottle (<1kg). In this case the freon has to be

recovered from an external bottle.

When a leak in the air conditioning device of the vehicle is detected during the vacuum test.

When the amount of cooling liquid contained in the internal bottle is too high (> 17,5 kg) and you try to

perform the recovery. In this case you should perform a charge in an external container.

When you try to perform a “vacuum” with the A/C station under pressure or if during the vacuum phase a

pressure increase occurs (> 0,5 bar). In this case, you should perform a recovery first.

When the interval for maintenance (150 h) is overdue – replace the internal filter.

When you try to perform the recovery (manually) and the pressure of the system to be checked is less than

0,5 bar – empty circuit.

When you try to charge the internal bottle and the external bottle is empty or it becomes empty before the set

charge is finished.

When the recovery from the external bottle is finished, you have to close the tap of the bottle and press the

key “ENTER” to recover the gas in the hoses.

Insufficient quantity of gas to perform the flushing of the A/C system, at leat 4kg required

CHAP. 4 - DESCRIPTION OF THE STATION

(please refer to the pictures in pag. 37-38)

Loading...

Loading...