15

Even though valves are very robust, they can be damaged by inappropriate commands, neglected

maintenance or by being used for purposes other than their intended use. All maintenance and/or

repairsshouldbecarriedoutbyexpert,qualiedpersonnel.However,rstandforemost,itisalways

advisabletoconsultSpiraxSarco.

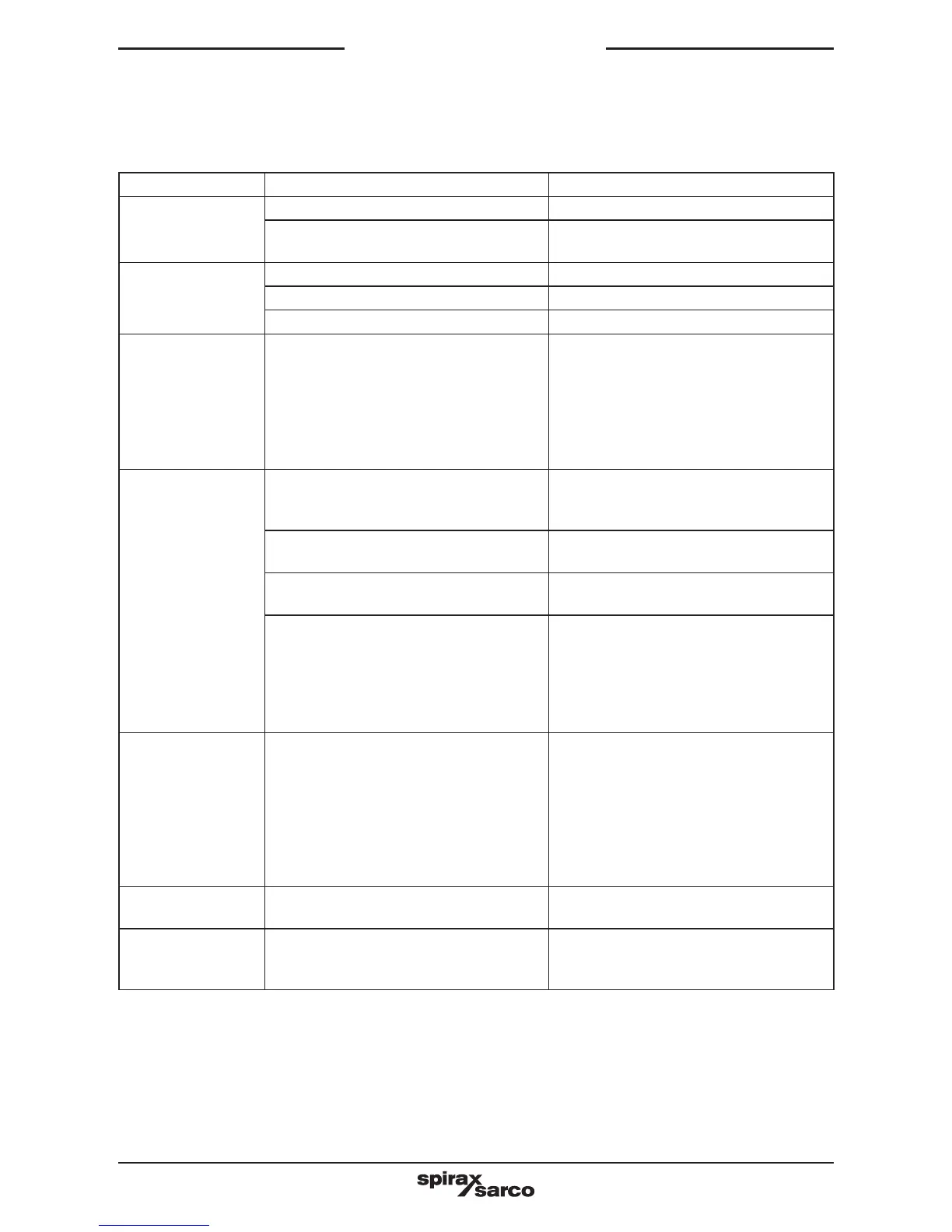

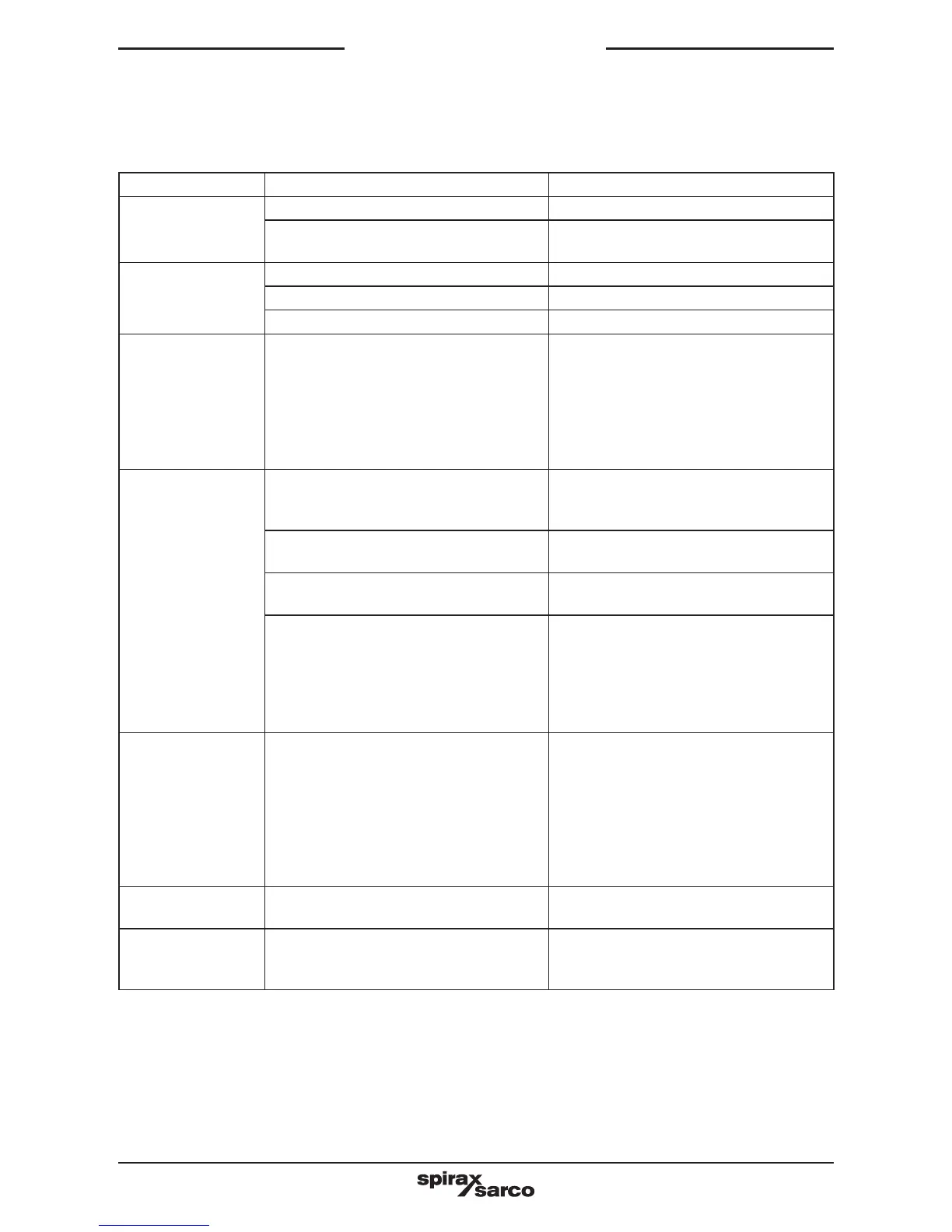

Symptom Possible cause Action

No ow

Valve closed. Open the valve.

Protective covers of the ange are

not removed.

Removetheangeprotections.

Reduced

owrate

Valve is not open enough. Open the valve.

Filter upstream the valve is dirty. Cleanorreplacethelter.

Pipeline is obstructed. Check and unclog the pipeline.

The stung

box is leaking

The stung box and/or the bellows

gasket are damaged for one or more

of the following reasons:

- material wear

- poor temperature resistance

-poorresistancetotheoperatinguid

- poor maintenance

Checkandtightenthestungboxand,

if necessary, add/replace graphite rings

to restore the tightness. Pay attention

nottoexcessivelyincreasethefriction

against the spindle. Immediately replace

the bellows.

Leakage between

seat and plug

assembly

Incorrect closure.

Close the valve by turning the wheel

anti-clockwise. Do not use additional

tools as levers.

Dierentialpressureistoohigh.

Use a plug with a balancing disc.

Checkthatthedirectionofowiscorrect.

Presence of impurities/solid particles

intheoperatinguid.

Thoroughly clean the gasket surfaces.

Fitalterupstreamthevalve.

Plug and/or seat have been damaged

for one or more of the following reasons:

- wear due to erosion/corrosion

- wear due to abrasion

-excessivemechanicalstressdueto

piping load and thermal stress.

Thoroughly clean the gasket surfaces.

If necessary replace the valve and/or

contactSpiraxSarco.

Leakage at

the body/cover

assembly

Gasket between the valve body and

cover is damaged for one or more of

the following reasons:

- wide temperature variations

- non-allowable pressure values

- poor temperature resistance

-poorresistancetotheoperatinguid

- poor maintenance

Replace the gasket between body

and cover.

Leaks at

connections

Flange bolts are not tightened enough.

Retightentheangebolts.

If necessary, renew the gaskets.

Breaking of

the connecting

anges.

Bolts have not been tightened evenly. Replace the valve.

8. Fault nding

Loading...

Loading...