3

1. General safety information

Safe operation of these products can only be guaranteed if they are properly installed, commissio-

ned,usedandmaintainedbyqualiedpersonnel(SeeSection11ofthisdocument)incompliance

with the operating instructions. General installation and safety instructions for pipeline and plant

construction, as well as the proper use of tools and safety equipment must also be complied with.

1.1 Intended use

Intended use Referring to the Installation and Maintenance Instructions, name-plate and Technical

Information Sheet, check that the product is suitable for the intended use/application.

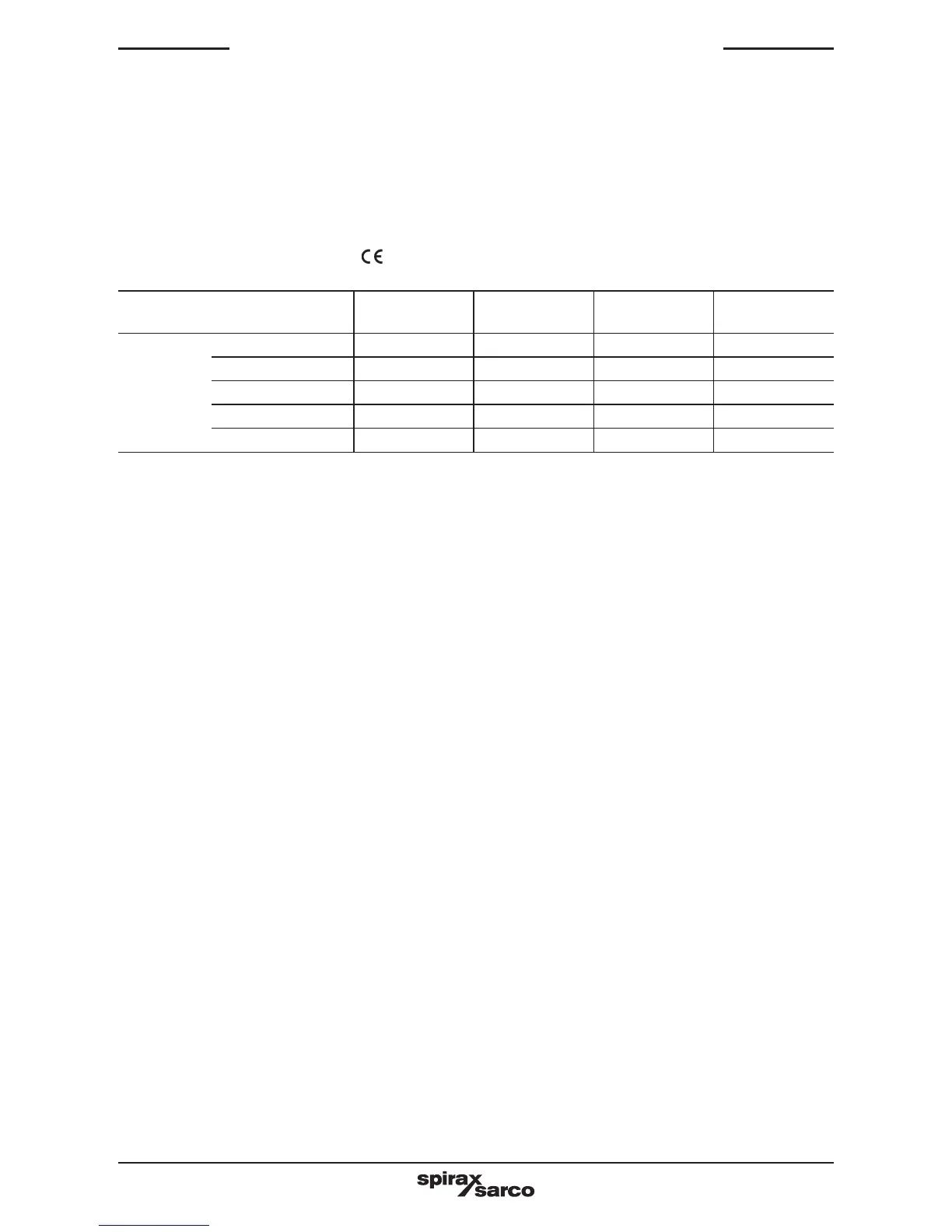

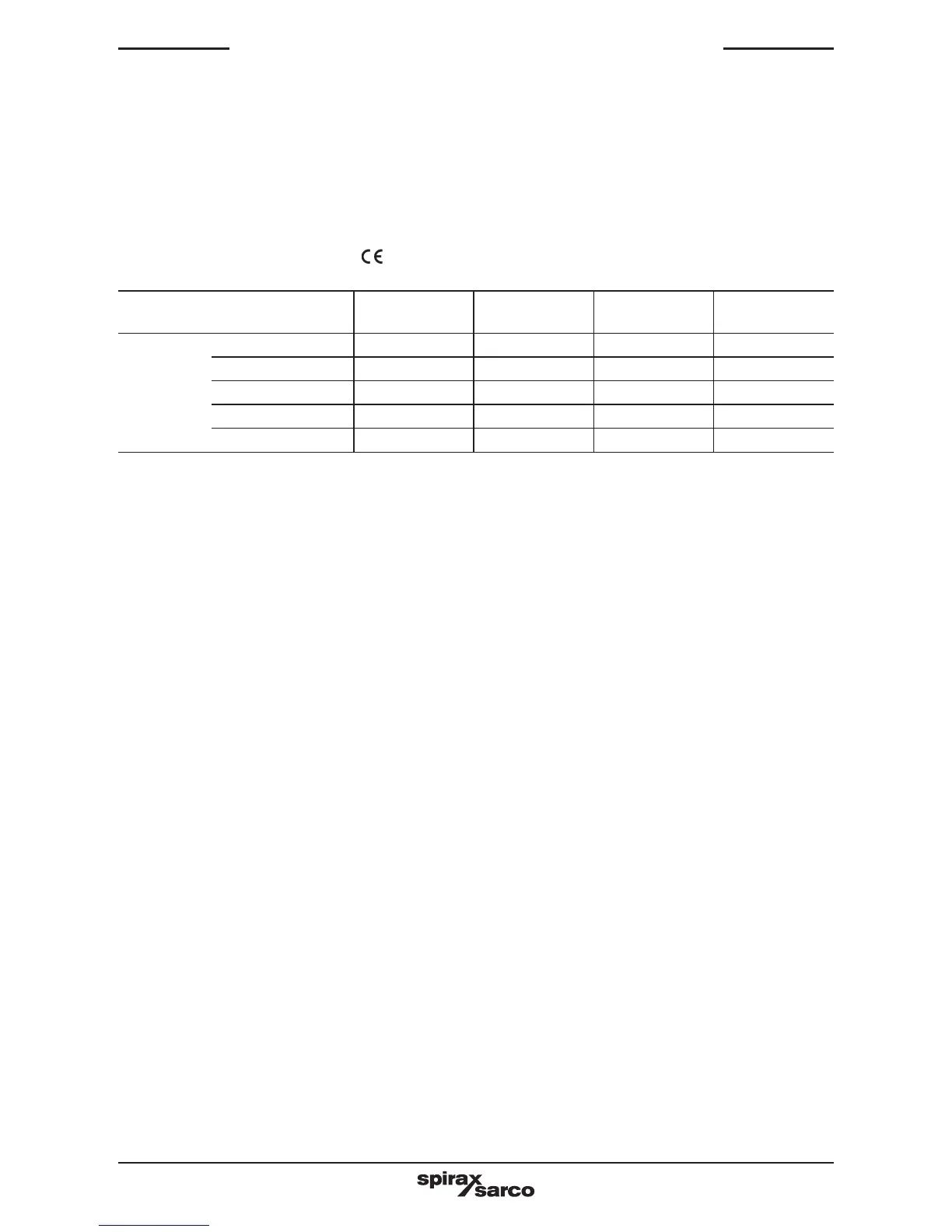

The products listed below comply with the requirements of the European Pressure Equipment

Directive 97/23/EC and carry the mark for DN 32÷250.

The products fall within the following Pressure Equipment Directive categories:

Product

Group 1

Gas

Group 2

Gas

Group 1

Liquid

Group 1

Liquid

BSK1

DN15÷25 SEP SEP SEP SEP

DN32÷50 1 SEP SEP SEP

DN65÷125 2 1 SEP SEP

DN150÷200 2 1 2 SEP

DN250 3 2 2 SEP

I) Theproductshavebeenspecicallydesignedforuseonsteam,compressedair,waterand

otherindustrialuidsthatareinGroup2oftheabovementionedPressureEquipmentDirective.

Theproducts'useonotheruidsmaybepossiblebut,ifthisiscontemplated,SpiraxSarco

shouldbecontactedtoconrmthesuitabilityoftheproductfortheapplicationbeingconsidered.

II) Checkmaterialsuitability,pressureandtemperatureandtheirmaximumandminimumvalues.

Ifthemaximumoperatinglimitsoftheproductarelowerthanthoseofthesysteminwhich

itisbeingtted,orifmalfunctionoftheproductcouldresultinadangerousoverpressureor

overtemperature occurrence, ensure a safety device is included in the system to prevent such

over-limit situations.

III) Determinethecorrectinstallationsituationanddirectionofuidow.

IV) SpiraxSarcoproductsarenotintendedtowithstandexternalstressesthatmaybeinduced

byanysystemtowhichtheyaretted.Itistheresponsibilityoftheinstallertoconsiderthese

stresses and take adequate precautions to minimise them.

V) Removetheprotectivecoverfromalltheconnectionsand,ifnecessary,theprotectivelm

from all the nameplates before installation on steam or high temperature plant equipment.

1.2 Access

Ensuresafeaccessandifnecessaryasafeworkingplatform(suitablyguarded)beforeattempting

to work on the product. Arrange suitable lifting gear if required.

1.3 Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

1.4 Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline at some previous time.

Consider:ammablematerials,substanceshazardoustohealth,extremesoftemperature.

1.5 Hazardous environment around the product

Consider:explosion riskareas, lackof oxygen(e.g. tanks,pits), dangerousgases, extremesof

temperature,hotsurfaces,rehazard(e.g.duringwelding),excessivenoise,movingmachinery.

Loading...

Loading...