IM-P693-13 EMM Issue 2

9

CP42 Conductivity Probe

1

2

3

4

56

7

8

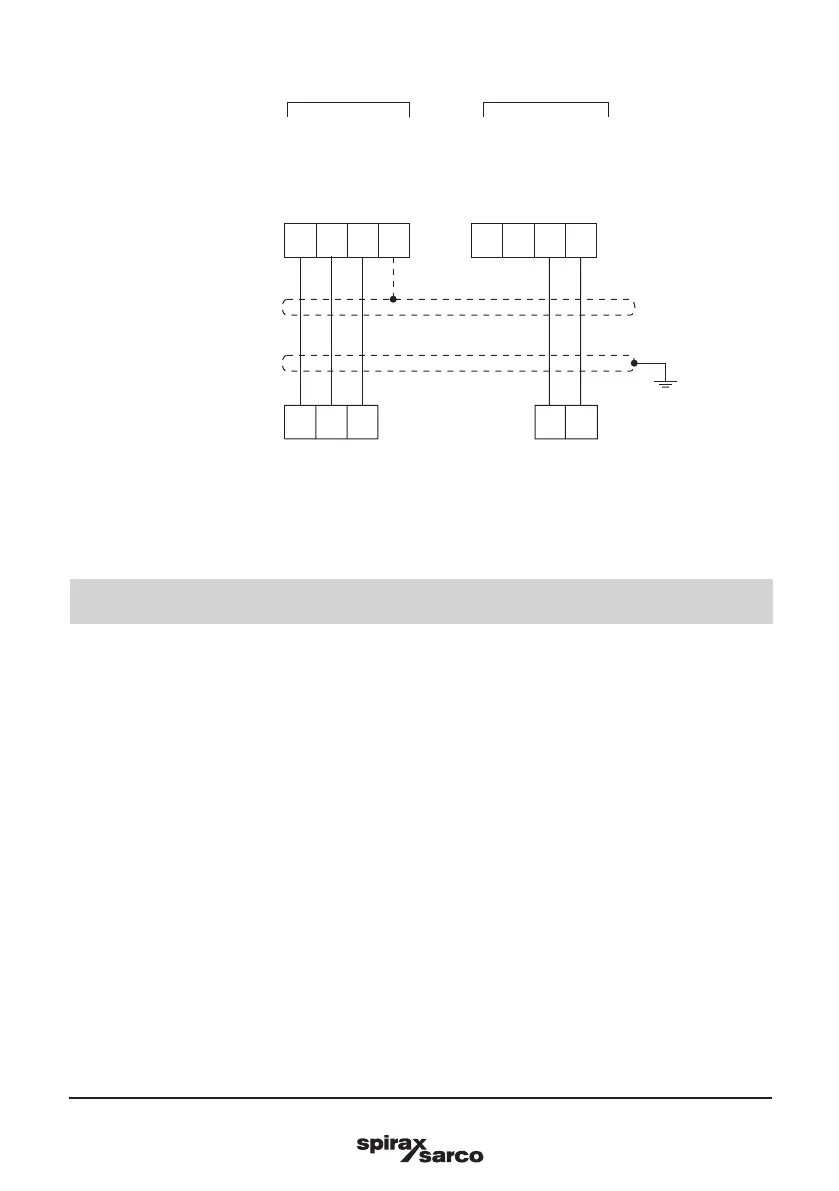

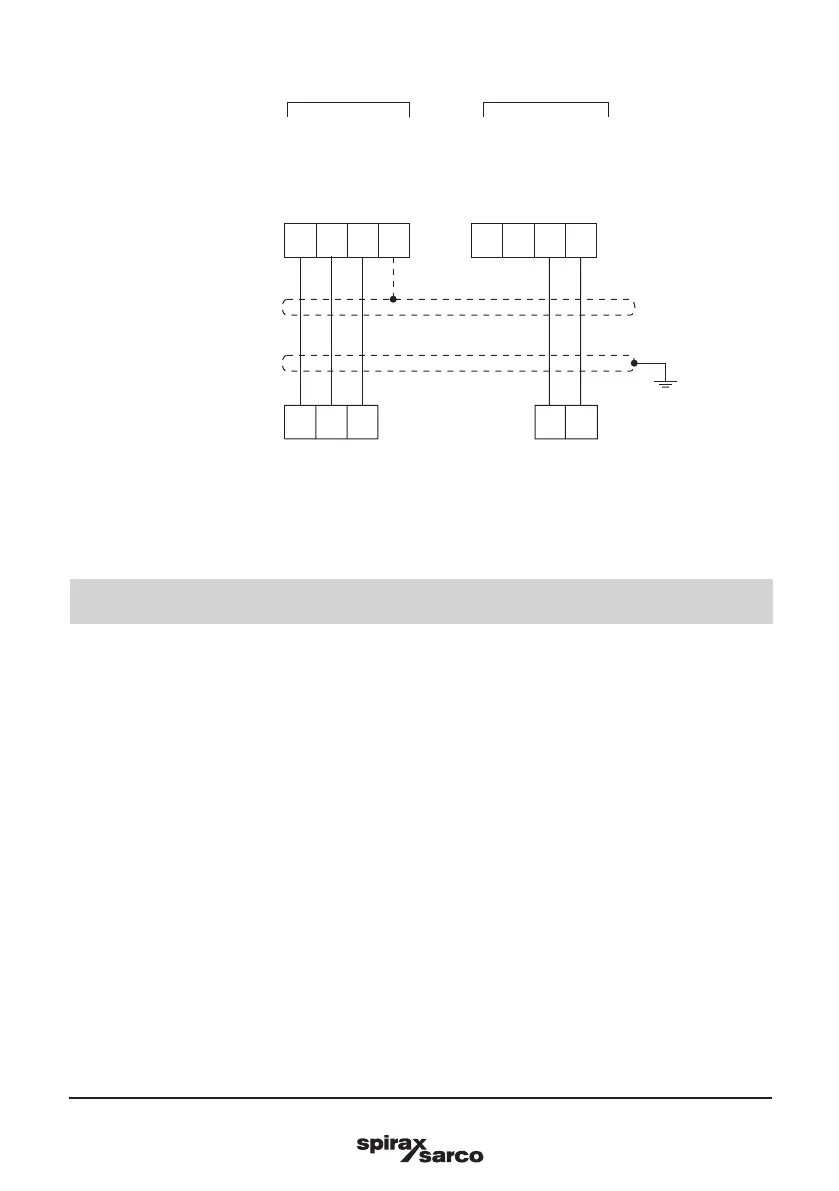

Driver tip

Sensor tip

Earth feedback

Earth

Earth

Feedback

Return

Drive

CP42 terminal

block TBK2

Probe Pt100

Fig. 4 Wiring diagrams

Ensure resistance from probe body to

pipework/boiler shell is less than 1 .

CP42 terminal

block TBK1

15 14 13 6 5

Screen

BCR3250 controller

The probe does not normally need regular maintenance. Remove, clean, and check the probe annually.

We also recommend that if the controller ever indicates a fault condition for over 12 hours that it is removed,

checked, and cleaned.

If scale should start to form on the probe, then it will normally be removed/made conductive by the automatic

conditioning system. However, this system is not a substitute for adequate water treatment. It is still possible

that under very severe conditions the probe may need extra cleaning.

To clean the probe tip manually

Probe body cleaning instructions - Use a cloth dampened with tap/de-ionised water or isopropyl alcohol.

Use of other cleaning materials could damage the product and invalidate the warranty.

Caution: The probe contains no user-serviceable components - any attempt to dismantle the unit will result

in permanent damage.

Remove the probe and clean with a wet cloth. For hard scale, fine wet-or-dry paper (600 grit maximum

coarseness) may be used on the tip. Do not use abrasives on the sleeve.

If excessive corrosion occurs at the probe tip, it may be necessary to replace the probe.

Refit the probe using PTFE tape rather than paste-type compound. See Section 3 'Installation'.

5. Maintenance

Loading...

Loading...