IM-S02-30 CMGT Issue 14

13

FT43, FT44, FT46 and FT47 Ball Float Steam Traps

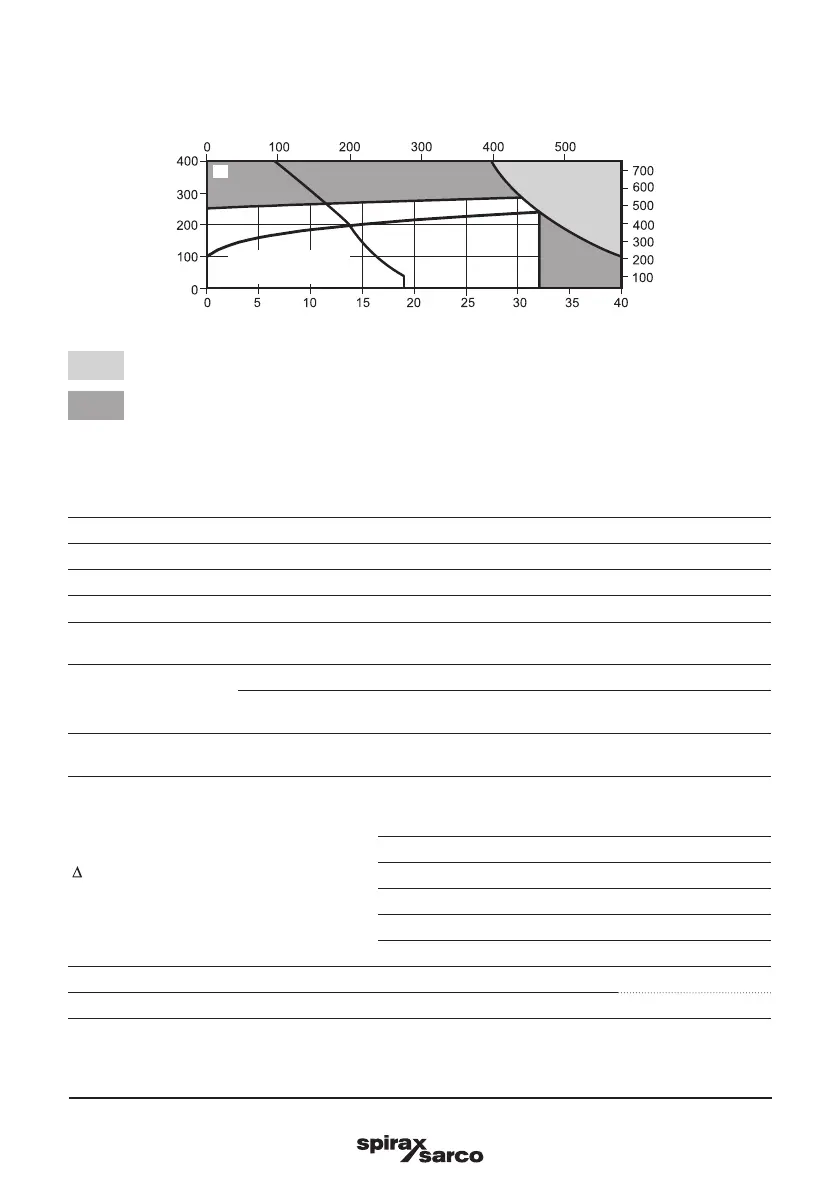

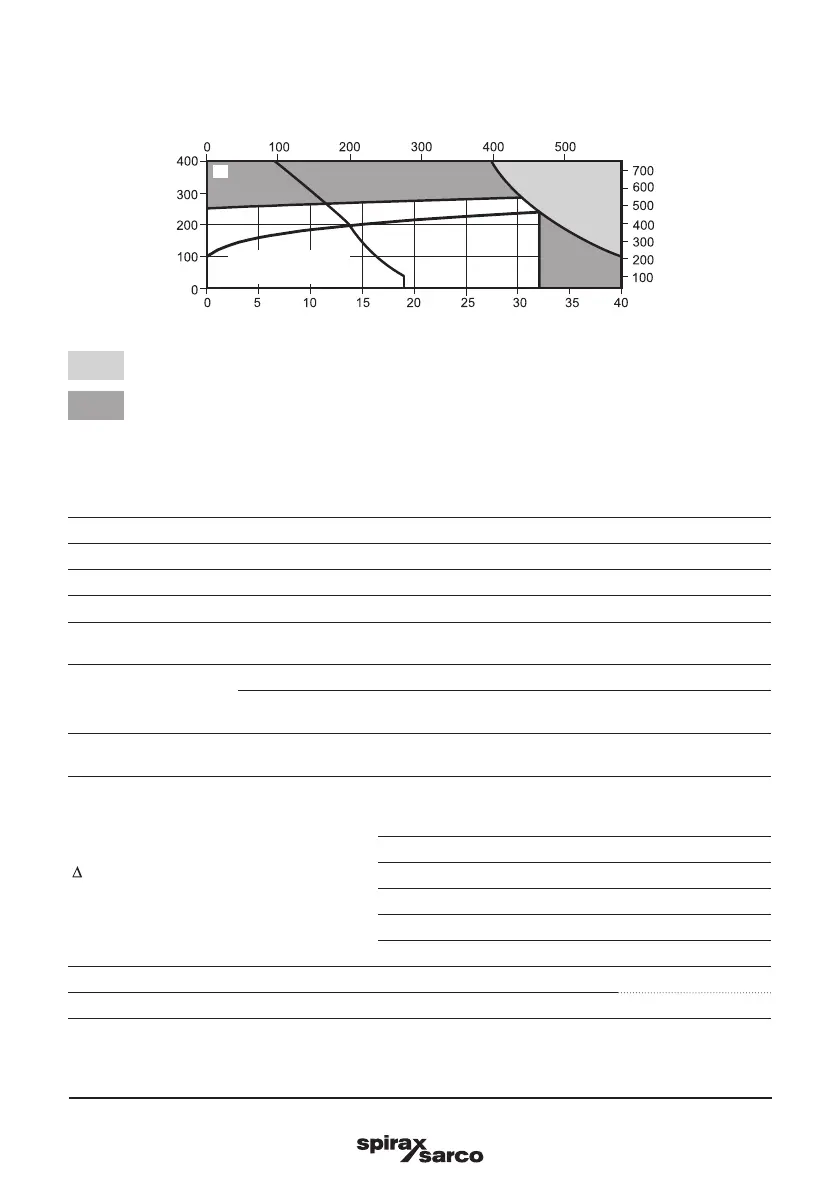

Pressure/temperature limits

The product must not be used in this region.

This product should not be used in this region as damage to the air vent may occur.

A - B Flanged EN 1092 PN40 and ASME (ANSI) 300.

A - C Flanged ASME (ANSI) 150.

Note: The use of the bimetallic element extends the superheat resistance to in excess of 400 °C.

Body design conditions PN40

PMA Maximum allowable pressure 40 bar g @ 100 °C (580 psi g @ 212 °F)

TMA Maximum allowable temperature 400 °C @ 27.4 bar g (752 °F @ 397 psi g)

Minimum allowable temperature -10 °C (14 °F)

PMO

Maximum operating pressure for saturated steam

service

32 bar g @ 239 °C (464 psi g @ 462 °F)

TMO

Maximum

operating

temperature

When fitted with a capsule 285 °C @ 30 bar g (545 °F @ 439 psi g)

When fitted with a bimetallic air

vent

400 °C @ 27.4 bar g (752 °F @ 397 psi g)

Minimum operating temperature

Note: For lower operating temperatures consult Spirax Sarco

0 °C (32 °F)

PMX

Maximum differential pressure

Size

DN15

DN20

DN25

DN40

DN50

FT46-4.5 4.5 bar 4.5 bar (65 psi)

FT46-10 10 bar 10 bar (145 psi)

FT46-14 14 bar - (203 psi)

FT46-21 21 bar 21 bar (304 psi)

FT46-32 32 bar 32 bar (464 psi)

Designed for a maximum cold hydraulic test pressure: 60 bar g (870 psi g)

Note: With internals fitted, test pressure must not exceed: 48 bar g (696 psi g)

Caution: The trap in its complete operational form must not be subjected to a pressure greater than 48 bar

otherwise damage to the internal mechanism may result.

Pressure bar g

Temperature °C

B

A

C

Pressure psi g

Temperature °F

Steam saturation

curve

Loading...

Loading...