IM-S24-15 CH Issue 4

13

4. Maintenance

4.1 Periodic maintenance

After 24 hours of operation

After 24 hours of operation check the flange bolts for tightness.

On valves with graphite stem seal packing compress the gland seal packing by tightening

the gland nut by ¼ of a turn. Care should be taken not to overtighten as this may cause the

spindle to lock-up.

Every 3 months of operation

Every 3 months of normal operation check the stem gland seal for leakage. In the case of

leakage proceed as follows:

- For valves with a PTFE gland seal renew the gland seal by following the procedure in

Section 4.2.

- For valves with a graphite stem seal packing compress the gland seal packing by tightening

the gland nut by ¼ of a turn. If leakage cannot be eliminated, renew the graphite gland seal

by following the procedure in Section 4.3.

Annually

Inspect the valve to check for wear or scale deposits. Worn or damaged parts, like the plug

or seat may need to be replaced, as well as the gland seal packing.

The graphite packing is normally subject to wear. Therefore it is recommended to renew the

packing rings annually.

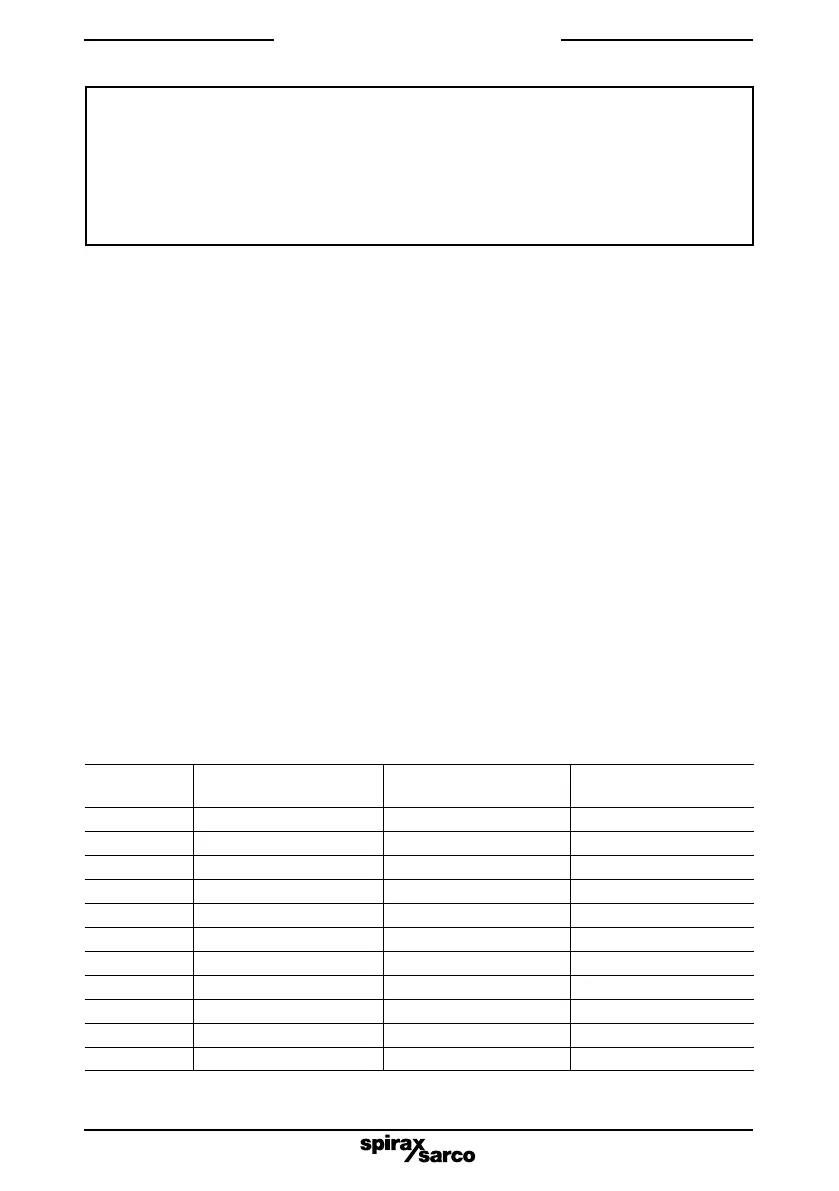

Table 1 Recommended tightening torques N m (lbf ft)

Size Seat (4) Bonnet nuts (15)

Gland nut

(chevron seals) (9)

DN15 (½") 40 ±5 (30 ±4) 30 ±1.5 (22 ±1) 25 - 30 (19 - 22)

DN20 (¾") 53 ±3 (39 ±2) 30 ±1.5 (22 ±1) 25 - 30 (19 - 22)

DN25 (1") 80 ±5 (59 ±4) 40 ±2 (29 ±1.5) 25 - 30 (19 - 22)

DN32 (1¼") 130 ±5 (96 ±4) 45 ±2 (33 ±1.5) 25 - 30 (19 - 22)

DN40 (1½") 220 ±5 (160 ±4) 45 ±2 (33 ±1.5) 25 - 30 (19 - 22)

DN50 (2") 150 ±5 (110 ±4) 65 ±3 (48 ±2.5) 25 - 30 (19 - 22)

DN65 (2½") 300 ±12 (220 ±9) 65 ±3 (48 ±2.8) 32 - 38 (24 - 28)

DN80 (3") 400 ±16 (295 ±12) 60 ±3 (44 ±2) 32 - 38 (24 - 28)

DN100 (4") 600 ±24 (442 ±18) 60 ±3 (44 ±2) 32 - 38 (24 - 28)

DN150 (6") 678 (500) 488 (360) 81 (60)

DN200 (8") 678 (500) 488 (360) 81 (60)

KEA61 and KEA63 Warning

The 316 type stainless steel used in the construction of this product particularly for

screwed or close fitting parts, is very susceptible to galling or cold welding. This is an

inherent characterisitic of this type of material and great care should therefore be taken

when dismantling or reassembling.

If the application permits, it is recommended that a lighter smear of a PTFE based grease

is applied to any mating parts before reassembly.

Loading...

Loading...