28

5.3.2 Spring kit - How to fit:

Note: Items 9 and 28 do not apply to the PN9400 actuator.

-

Remove actuator from valve as described in Section 5.1.

-

Lubricate the threads of the three long hex. head screws with a PTFE based grease

before releasing the tension in the springs.

-

Loosen and remove the short housing screws and nuts (22, 23 and 24).

-

Holding each nut with a spanner, rotate the three long hex. head screws a few turns at

a time. Remove the screws and upper housing (2).

Note 1: On certain spring ranges 3 off longer housing screws are fitted to safely allow

spring decompression (23). These should be removed last after all other bolts are

removed and should be loosened evenly to prevent distortion of the housing.

-

Taking care not to damage the 'O' ring (9) fitted between the diaphragm support plate

(3) and spacer (8), remove the washer (28) and the diaphragm (4).

-

Using a spanner to hold the actuator spindle (6), loosen and withdraw the bolt (21).

Remove the washer (7), the diaphragm (4) and the diaphragm plate (3). Remove the

springs (5) taking note of their location.

-

Replace the new springs (5) locating them in the same position as the previous set.

-

Refit all other items in reverse order. Using a spanner, to hold the actuator spindle so

that the diaphragm sits evenly in the lower housing, refit the top housing (2) and securing

nuts and screws (22, 23 and 24).

Note 2: Tighten the housing securing bolts evenly to avoid distortion. 3 off longer

housing screws (23) are provided on some spring ranges to cater for longer springs.

If supplied, these should be positioned 120° apart and tightened evenly prior to fitting

the remaining screws.

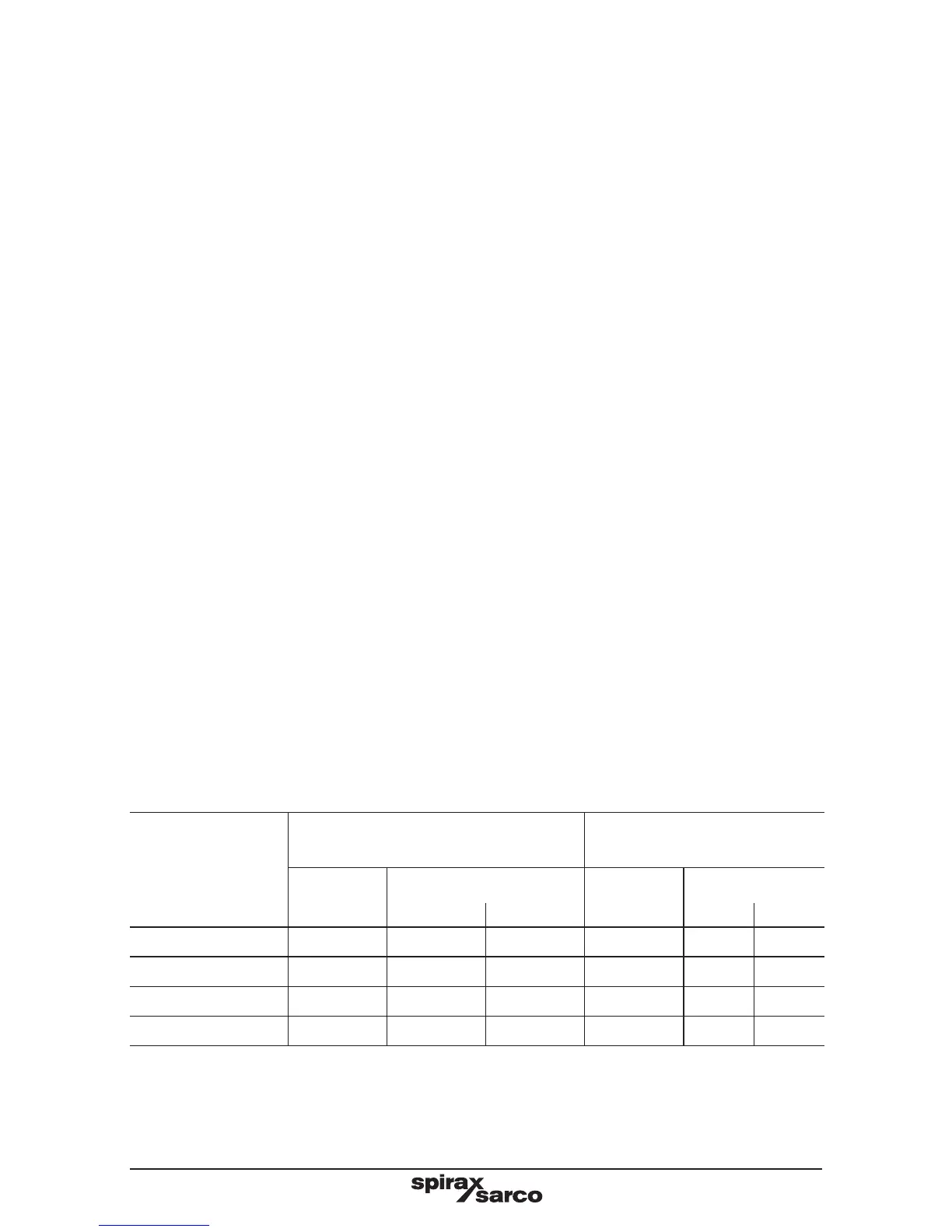

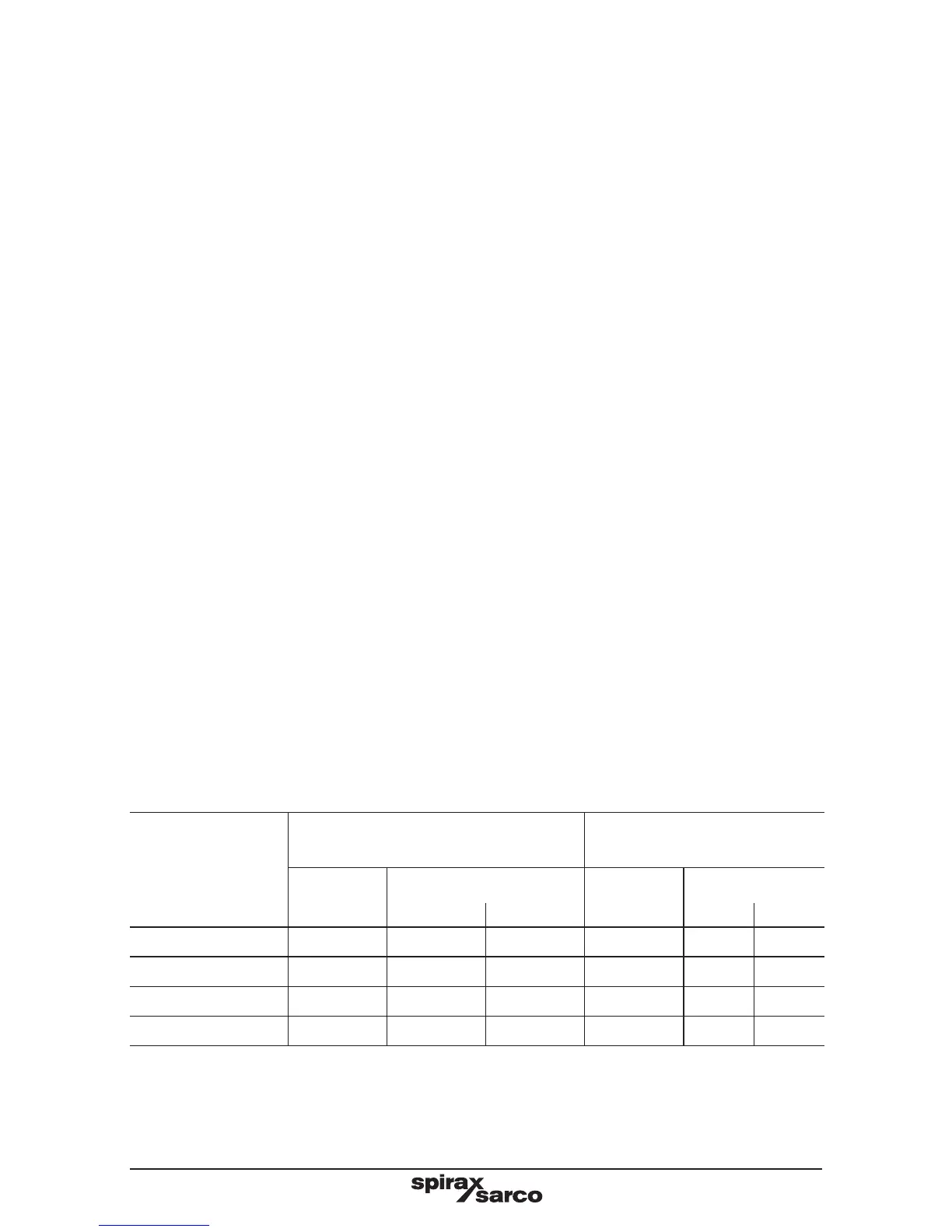

Refer to Table 1, for the recommended tightening torques.

Table 1 Recommended tightening torques

Actuator series

Screws and nuts

(Items 22, 23 and 24)

Bolt

(Item 21)

Size Torque Size Torque

N m lbf ft N m lbf ft

PN9100 M6 7 5.2 M12 40 29.5

PN9200 M10 35 26.0 M12 40 29.5

PN9300 M10 35 26.0 M12 40 29.5

PN9400 M10 60 44.0 M16 40 29.5

Loading...

Loading...