Do you have a question about the Spirax Sarco 1600V and is the answer not in the manual?

Details on instrument dimensions and panel mounting procedures.

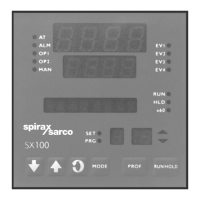

Explains indicators for operation modes and system states.

Shows the current process variable and error messages.

Displays the current setpoint value.

Visual representation of a variable as a percentage.

Details on the 'F' key and '*' key functions.

Details standard and optional power supply connections.

Describes generic and analogue output connection configurations.

Details the isolated transmitter supply connection.

Explains isolated digital input connection specifications.

Describes auxiliary inputs and current transformer connections.

Details serial line connection configurations for communication.

Lists available input types like thermocouples and RTDs.

Displays information like serial code and software version.

Accesses custom menus for data configuration.

Used for configuring control parameters.

Configuration for serial communications.

Settings related to input configurations.

Configuration of output settings.

Protection code settings for the instrument.

Hardware configuration settings.

Input linearisation settings.

Custom data menu.

User calibration options.

Explains Proportional, Derivative, and Integral control actions.

Step-by-step guide for manually tuning PID parameters.

Procedure for disabling/enabling the instrument's power function.

Automatic calculation of PID parameters for optimal control.

Continuous or one-shot tuning for system oscillation reduction.

Details on proportional-only and relative gain heat/cool control.

Describes absolute, deviation, and symmetrical alarm configurations.

Monitors load current variations using a current transformer.

Detects control loop interruptions, like broken heaters.

Gradually increases output power upon instrument startup.

Configuration and operation of timers and multiple setpoints.

Enables multiple setpoints and controls setpoint change ramps.

Defines parameters like actuator time, minimum pulse, and dead band.

Details floating and feedback valve control types (V0, V1, V2).

Allows custom correction of main input readings via four values.

Details current transformers for current measurements.

Description of RS232 cable for PC configuration.

Guide to configuring the instrument's order code.

Critical safety advice for installation and operation.

| Brand | Spirax Sarco |

|---|---|

| Model | 1600V |

| Category | Controller |

| Language | English |

Loading...

Loading...