TI-P146-05

CMGT Issue 6

Page 4 of 5

UFT32 Sealed Stainless Steel Ball Float Steam Trap (for use with Pipeline Connectors)

Safety information, installation and maintenance

For full details see the Installation and Maintenance Instructions (IM-P146-01) supplied with the product.

Installation note:

The UFT32 can be installed on any pipeline connector, but must be installed in a horizontal plane with the ‘TOP’ label facing

upwards See separate Installation and Maintenance Instructions for Spirax Sarco pipeline connectors (IM-P128-06, IM-P128-11

and IM-P128-13).

Disposal

The UFT32 trap unit is manufactured from stainless steel and is therefore totally recyclable. No ecological hazard is anticipated with

the disposal of this product provided due care is taken.

How to specify

Steam traps shall be sealed ball float traps UFT32 type suitable for a differential operating pressure of either 4.5, 10, 14, 21 or 32 bar.

Traps to be zero maintenance and be connected to a separate pipeline connector by two screws to allow for quick and simple installation/

replacement.

For example Spirax Sarco UFT32-32 ball float steam trap.

How to order

The UFT32 is supplied as follows:-

1. The swivel pipeline connector

PC10HP Standard connection

PC20 One integral ISO valve plus 'Y' type strainer

IPC21 One integral ISO valve plus 'Y' type strainer and Spiratec sensor

PC3

_

One integral ISO valve

PC4

_

Two integral ISO valves

2. The STS17.2 steam trap station

3. The UFT32 trap complete with inner and outer gaskets and two connector screws. These items will be supplied in a protective box.

Note: Any optional extras need to be specified at the time of order placement.

How to order example:

1 off Spirax Sarco DN20 PC10HP pipeline connector with socket weld connections.

or

1 off DN20 STS17 steam trap station having socket weld connections.

and/or if you are ordering a replacement for an existing unit:

1 off Spirax Sarco UFT32-21 sealed stainless steel ball float steam trap.

plus

1 off Spirax Sarco insulating jacket to fit a UFT32.

Please note: The above items are to be supplied with connector screws and gaskets.

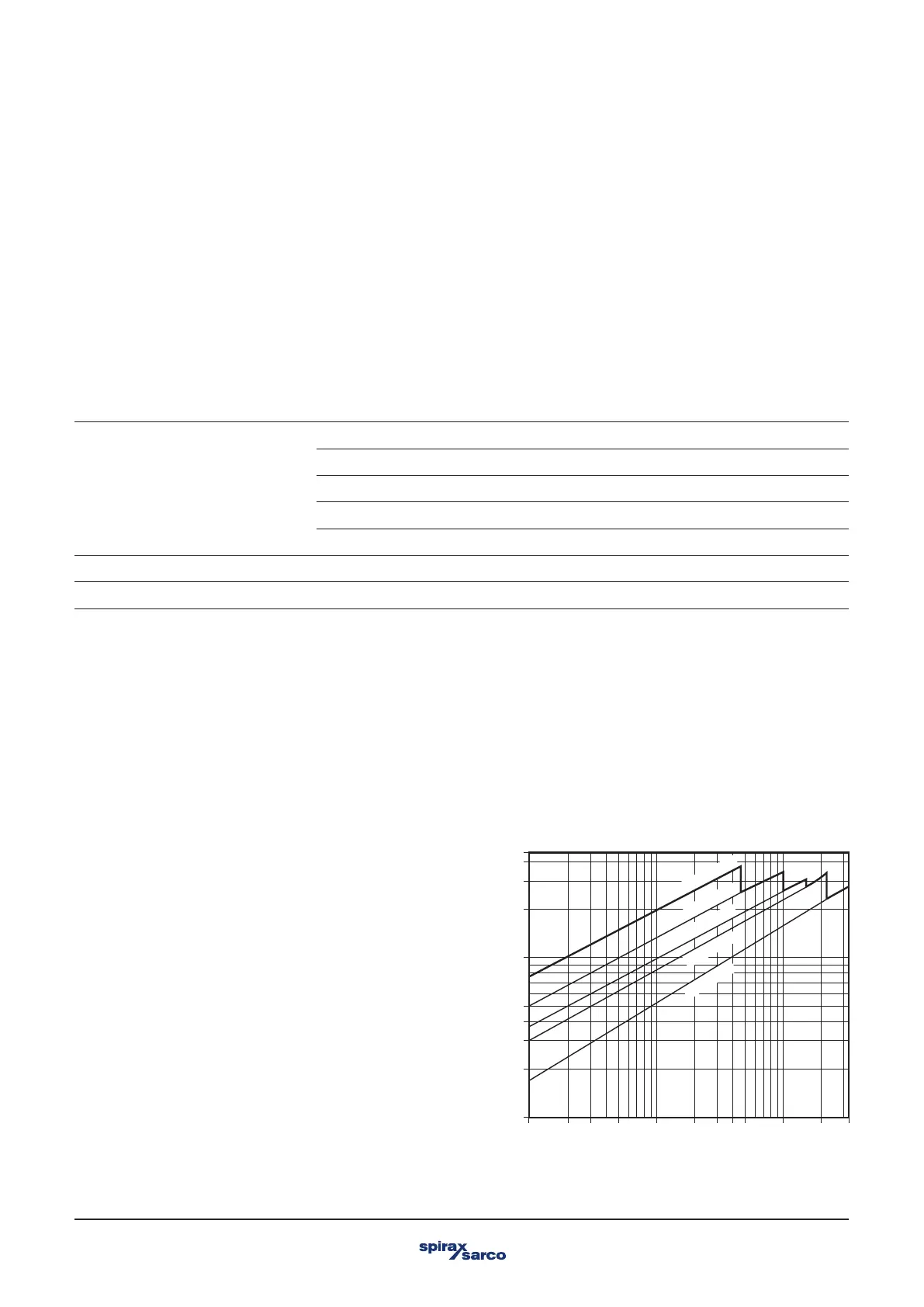

Capacities (in accordance with ISO 7842)

Note: Capacities shown are based on discharge at saturation

temperature. When discharging sub-cooled condensate the air

vent provides extra capacity. Under start-up conditions the

thermostatic air vent will be open, and will provide additional

condensate capacity to the main valve assembly. This will provide

a minimum of 100% increased capacity above the hot condensate

figures shown.

For example:

A UFT32-14 has a hot condensate capacity of 195 kg/h at 5 bar

differential. The cold start-up capacity will be a minimum of

390 kg/h.

Differential pressure bar (x 100 = kPa)

Condensate kg/h

Loading...

Loading...