18

© SPX

Form No. 1000572

Rev. 0 February 8, 2012

Sound Reduction - Electrically Powered Motor

The electrically powered hydraulic pump operates in the 85-90 dB A range. If further sound reduction is

desired, any of the following options will help reduce the sound level.

1. Install a pressure switch to automatically shut off the motor when maximum pressure is reached

(holding cycle).

2. Install casters (7.5L (2 Gallon) reservoir only).

3. Contact Power Team Hydraulic Technology technical support for products more suitable to your

application.

Hose Connections

CAUTION: Contamination of the hydraulic uid could cause the valve to malfunction.

Loss of the load or personal injury could result.

IMPORTANT: Sealant tape or non-hardening sealer tape can be used to seal hydraulic

connections if only one layer of tape is used. Apply tape carefully, two threads back, to

prevent it from being pinched by the coupler and broken off inside the system. Loose

pieces of sealant could travel through the system and obstruct the ow of uid or cause

jamming of precision-t parts.

Storage

Store the unit in a dry, well-protected area where it will not be exposed to corrosive vapors, dust, or

other harmful elements. If a unit has been stored for an extended period of time, it must be thoroughly

inspected before it is used.

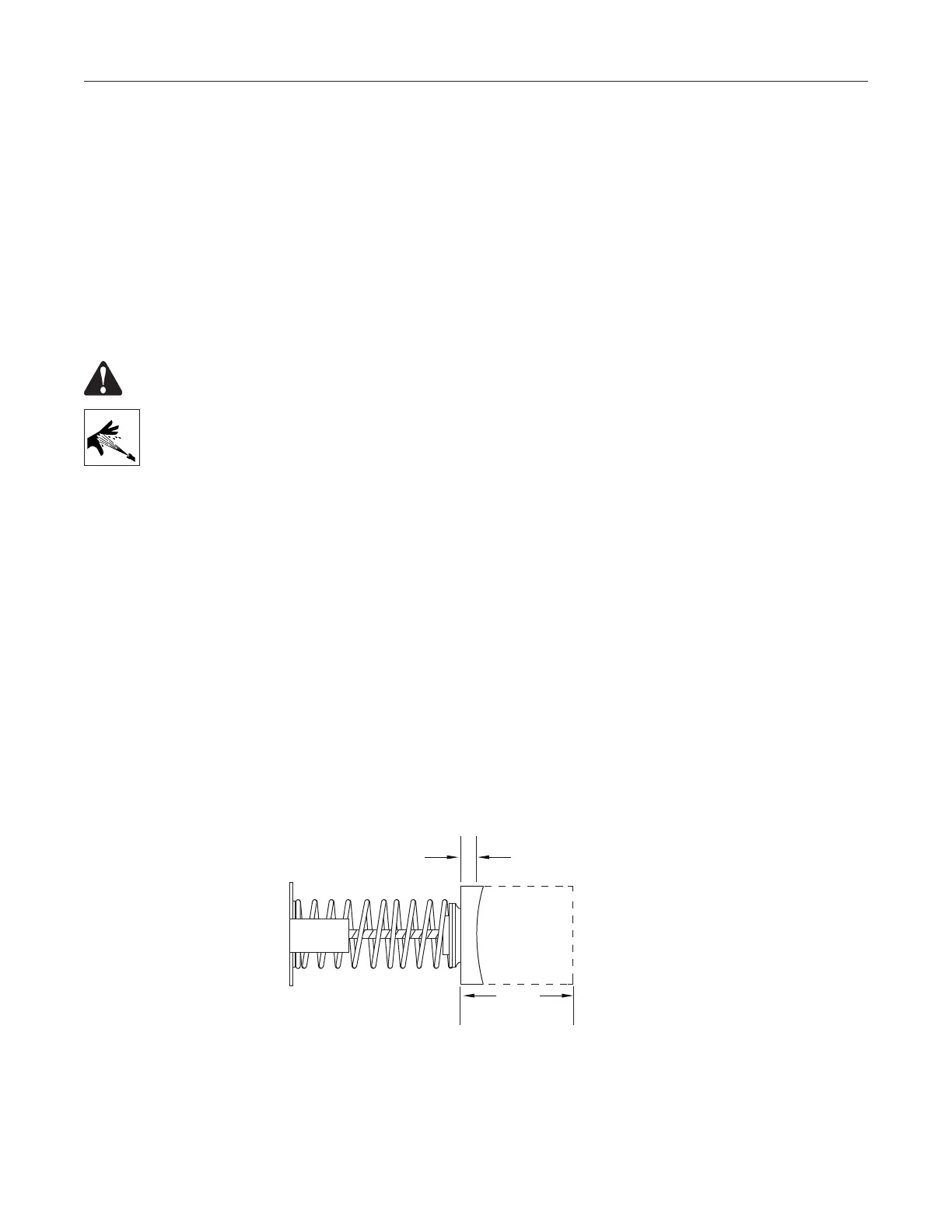

Checking Brushes on Electric Motors

To help prevent premature failure of the armature, check the brushes every 100 hours or 100,000

pressure cycles:

1. Remove the brush holder caps and brush assemblies.

2. The brush assemblies must be replaced if they are 4.7mm (3/16") long or less. See Figure 9.

3. Install brush assemblies and brush holder caps.

General Maintenance continued

Figure 9. Brush Inspection

22 mm (7/8")

(new)

Replace when

Loading...

Loading...