Operating Instructions Form No. 102875

SET-UP INSTRUCTIONS

Filling The Pump Reservoir Or Bladder

NOTE: Most pumps are shipped without hydraulic fluid in the reservoir. Hydraulic fluid may have been

shipped with the pump in a separate container. If hydraulic fluid is needed, use 215 SSU @ 100° F (47 cSt @

38° C) hydraulic fluid. Pumps with a bladder are shipped with hydraulic fluid in the bladder.

1. Clean the area around the filler cap to remove all dust and grit. Any dirt or dust in the hydraulic fluid can damage

the polished surfaces and precision-fit components of this pump.

2. Retract all cylinder(s) to their return position.

3. Remove the filler cap and insert a clean funnel with a filter. Fill the reservoir with hydraulic fluid to 1" (25,4 mm)

(PE8, PE17 & PE30 series pumps to 1-1/2" [38,1 mm]) from the cover plate. PR10 series pump bladder must be

filled completely. Replace the filler cap. IMPORTANT: For PR10 series pumps, tighten filler cap 1/2 - 1 turn

after o-ring contacts sealing surface. Overtightening can cause pump damage on bladder equipped

pumps.

Hydraulic Connections

Remove the thread protectors or dust covers from the hydraulic ports if applicable. Clean the areas around the fluid

ports of the pump and cylinder. Inspect all threads and fittings for signs of wear or damage, and replace as needed.

Clean all hose ends, couplers and union ends. Connect all hose assemblies to the pump and cylinder. Use an

approved, high-grade pipe thread sealant to seal all hydraulic connections. Tighten securely and leak-free but do not

overtighten.

Hydraulic lines and fittings can act as restrictors as the cylinder or ram retracts. The restricting or slowing of the fluid

flow causes back pressure that slows the cylinder’s or ram’s return. Return speed also varies because of the

application, condition of the cylinder or ram, inside diameter of hose or fitting, length of the hose, and the temperature

and viscosity of the hydraulic fluid.

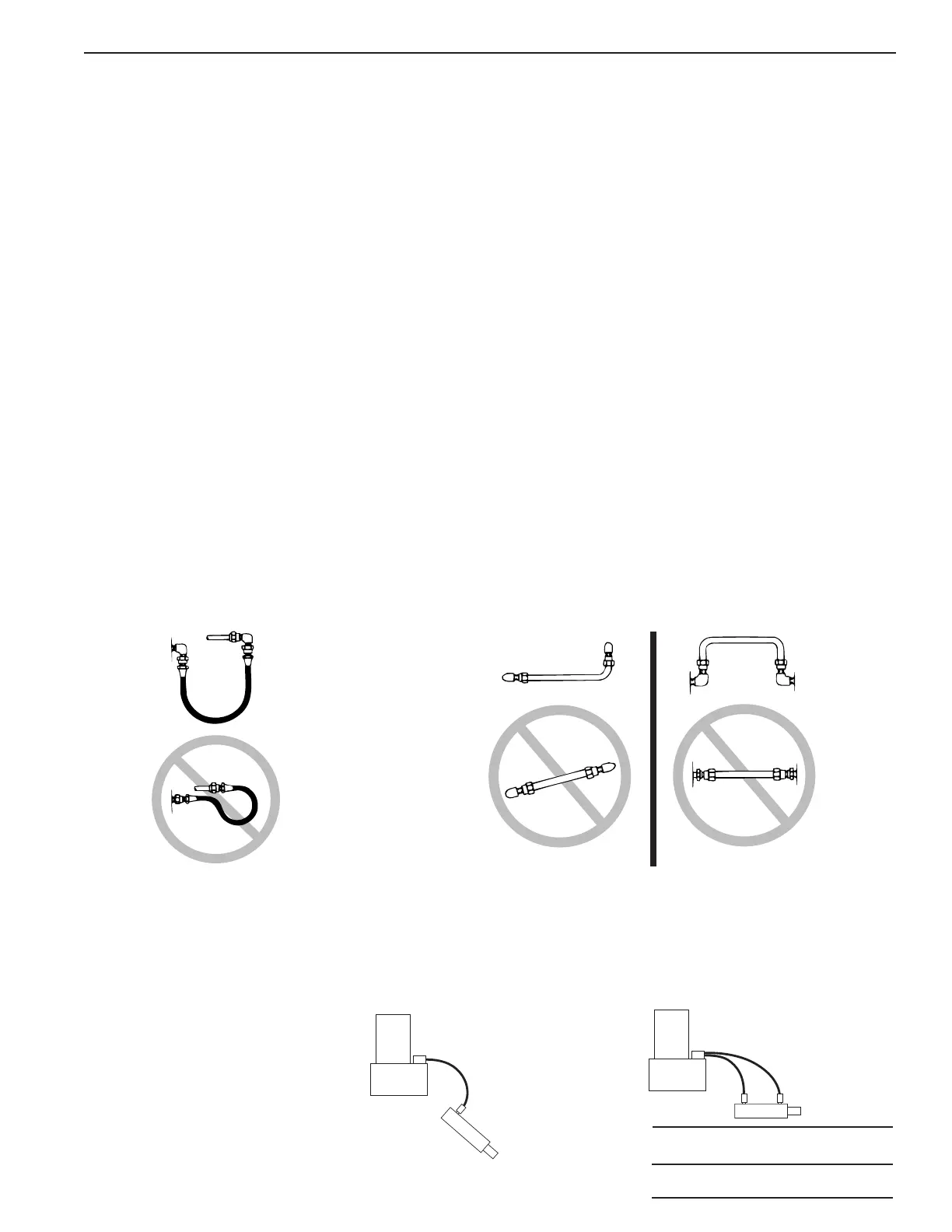

HOSES TUBING

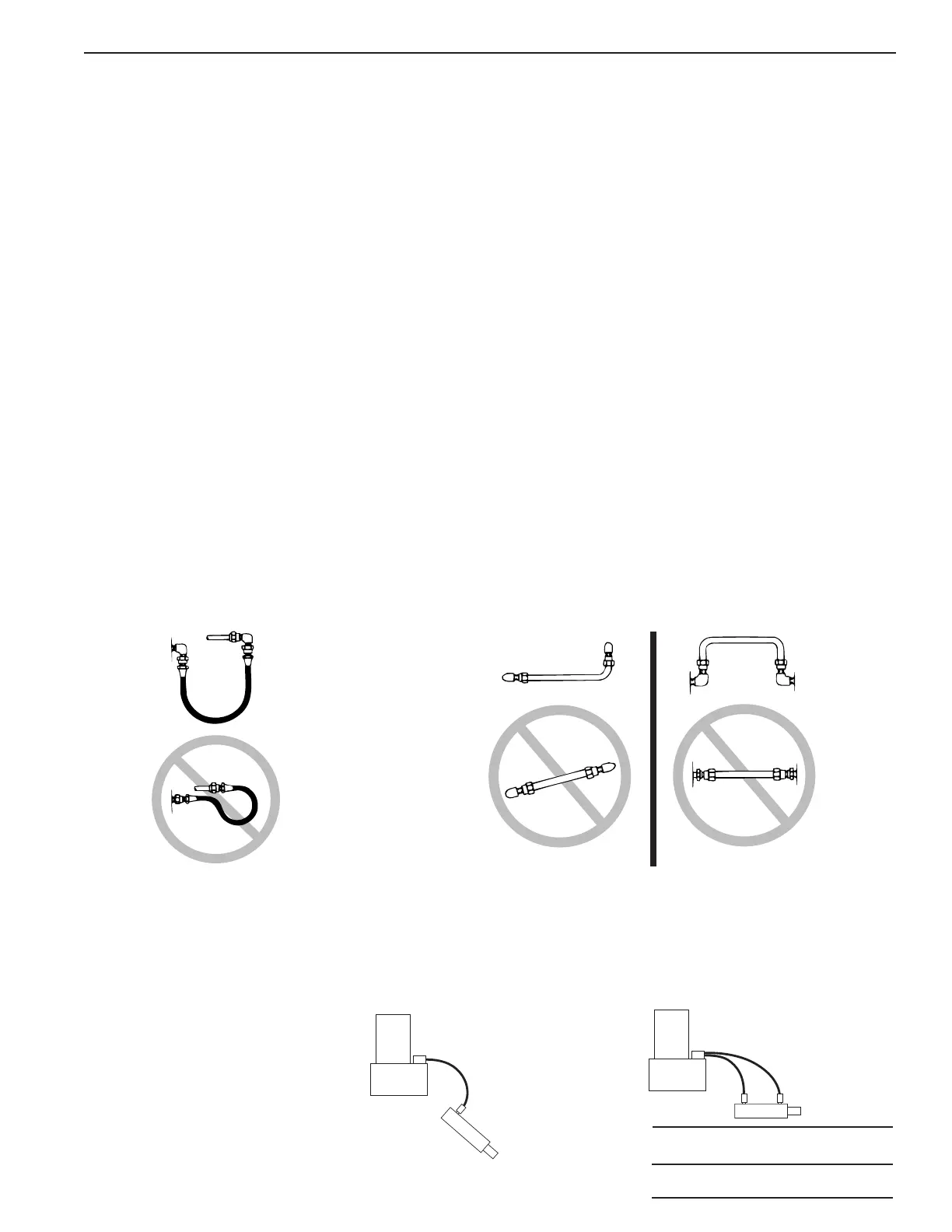

Bleeding The System

After all connections are made, the hydraulic system must be bled of any trapped air. Refer to the diagrams below.

With no load on the system and the pump vented and positioned higher than the cylinder or ram, cycle the system

several times. Check the reservoir for possible low fluid level and fill to proper level with approved, compatible

hydraulic fluid as necessary (see “Filling The Pump Reservoir Or Bladder” section under Set-up Instructions).

Sheet No. 3 of 8

Rev 10 Date: 02 Mar 2005

INCORRECT

CORRECT

CORRECT

CORRECT

INCORRECT

INCORRECT

IMPORTANT: Some spring

return cylinders or rams have

a cavity in the rod which

forms an air pocket. This type

of cylinder or ram should be

bled when positioned upside

down or lying on its side with

the port facing upward.

System with a

single-acting

cylinder

System with a

double-acting

cylinder

Loading...

Loading...